Edited by: www.immyhitech.com

Wheat mills represent a cornerstone of global food production, transforming raw wheat grains into essential flour products that feed billions worldwide. In today's advanced agricultural landscape, wheat mills have evolved from simple grinding mechanisms to sophisticated integrated production systems that incorporate cutting-edge technology for optimal efficiency and quality control. Modern wheat mills must balance multiple competing demands: producing consistent, high-quality flour while maximizing yield, minimizing energy consumption, and ensuring food safety throughout the process. The journey from grain to flour involves a complex series of precisely calibrated steps, each requiring specialized equipment designed to perform specific functions within the integrated wheat flour mill production line.

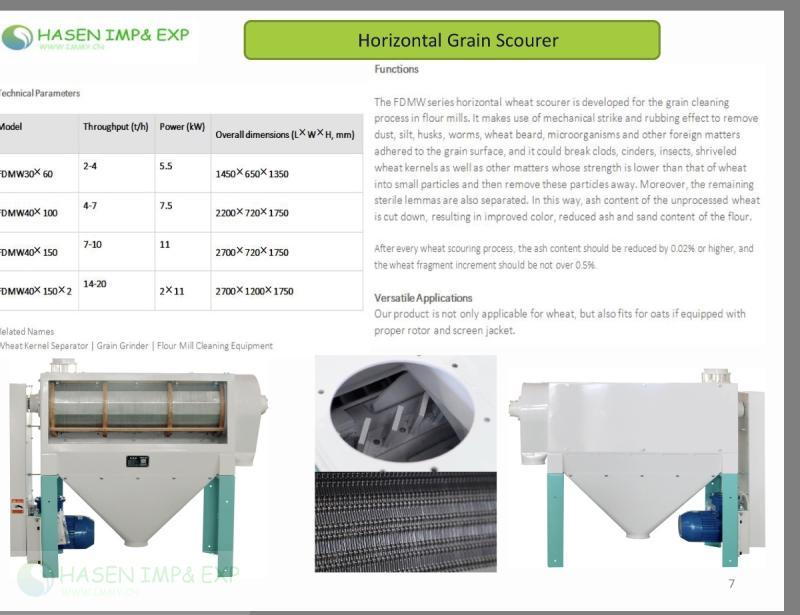

Contemporary wheat mills perform several critical functions that go far beyond simple grain crushing. First, cleaning and preparation removes impurities, foreign materials, and damaged grains through specialized equipment like the Intensive Wheat Scourer offered by Wuxi Hasen wheat mills, which comes in two efficient models (30/60 friction malting machine and 45/80 friction malting machine). This preparation phase is crucial for ensuring final flour quality and preventing equipment damage. Next comes the milling and separation stage, where roller mills break down wheat kernels into their constituent parts, and plansifters classify these intermediate products by particle size. Wuxi Hasen wheat mills provides specialized roller mills that serve as core equipment for large and medium-sized flour milling operations, capable of processing not only wheat but also black rice, barley, maize (corn), sorghum, and other grains with remarkable efficiency.

The third essential function is purification and refinement, where machines like purifier series cleaning equipment separate bran and germ from endosperm to create various flour grades. Wuxi Hasen wheat mills offers complete purifier series cleaning machines specifically designed for integrated wheat flour mill production lines. This comprehensive approach ensures that every aspect of wheat processing is optimized for maximum yield and quality. Finally, modern wheat mills incorporate automation and control systems that monitor and adjust the entire process in real-time, a capability that distinguishes leading manufacturers like Wuxi Hasen wheat mills, who supply intelligent plant controllers to create automated, digital, and even unmanned facilities that dramatically improve working efficiency.

Modern wheat mills serve diverse applications across the global food industry, with specialized equipment configurations tailored to specific end products. Industrial-scale bakeries require consistent, high-protein flours for bread production, while pastry manufacturers need softer, lower-protein flours for cakes and pastries. Integrated wheat flour mill production lines must be versatile enough to produce multiple flour grades simultaneously to meet varied market demands. For artisanal bakeries and specialty food producers, smaller-scale but equally sophisticated wheat mills offer the flexibility to create unique flour blends with specific characteristics.

Beyond traditional flour production, contemporary wheat mills support value-added processing applications. Some facilities incorporate additional equipment to produce pre-mixes, fortified flours with added vitamins and minerals, or specialty products like semolina for pasta production. The adaptability of systems from Wuxi Hasen wheat mills extends to processing other cereal grains, allowing facilities to diversify their product offerings. For international markets, wheat mills must accommodate varying wheat varieties with different hardness, moisture content, and protein levels—a challenge addressed by customizable solutions that can be precisely adjusted to local conditions. The Wuxi Hasen wheat mills approach includes providing complete engineering design, manufacturing, installation, training, commissioning, and project contracting services to ensure optimal performance regardless of geographical location or specific production requirements.

With over 30 years of industry experience, Wuxi Hasen wheat mills has established itself as a premier provider of complete grain and oil processing solutions. The company functions not merely as an equipment supplier but as a general solution service provider and project system integration service provider, offering comprehensive services from technology research and development to final commissioning. This holistic approach ensures that every integrated wheat flour mill production line operates at peak efficiency from day one. Wuxi Hasen wheat mills emphasizes innovation through their machines and efficiency services, developing specialized equipment like the High Plansifter—one of their main grain oil equipment pieces specifically designed for the flour mill industry—which classifies intermediate products according to particle size with exceptional precision.

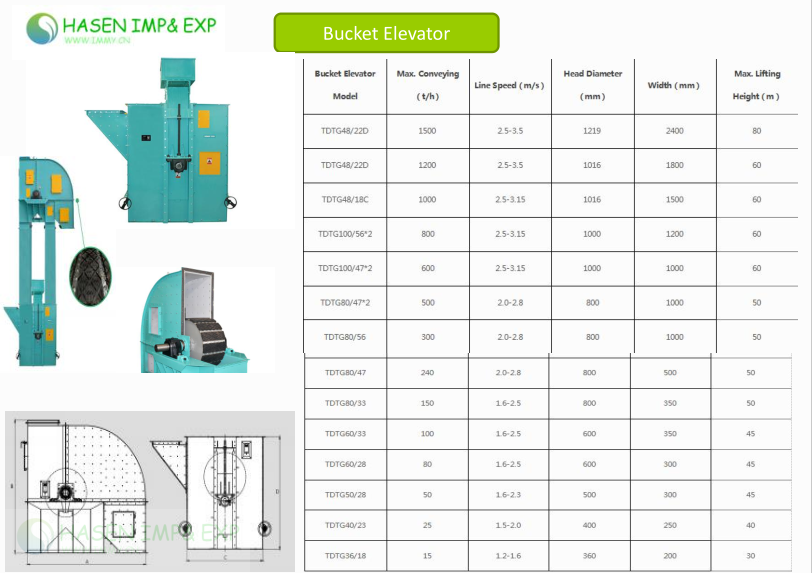

The company's product portfolio encompasses every component needed for modern wheat mills, from core milling equipment to advanced control systems. Their completed set flour making plant machines include everything required for both the cleaning workshop and flour milling workshop. For material handling, Wuxi Hasen wheat mills provides customized silo and conveyor plans featuring bucket elevators, scraper conveyors, and round screwed conveyors tailored to specific facility layouts and capacity requirements. Additionally, their commitment to technological advancement is evident in their intelligent plant controller solutions, which enable factories to become increasingly automated, digital, and even unmanned—significantly improving working efficiency while reducing labor costs and human error. For facilities requiring advanced material handling, Wuxi Hasen wheat mills even supplies robot stacking systems for modern production environments, saving both labor and valuable floor space while dramatically increasing productivity.

Wuxi Hasen wheat mills distinguishes itself through specialized equipment designed for specific functions within the integrated wheat flour mill production line. Their roller mills serve as the core host equipment for large and medium-sized operations, engineered for durability and precision in grinding various grains. These robust machines maintain consistent particle size reduction, which is essential for producing uniform flour quality. Complementing these are the company's High Plansifters, which utilize advanced screening technology to separate milled products by particle size at various stages of the milling process—a critical function that determines the final characteristics of different flour grades.

For the vital cleaning phase, Wuxi Hasen wheat mills offers specialized equipment including Intensive Wheat Scourers available in two efficient models and Indented Cylinder Separators capable of processing buckwheat, oats, and similar grains. Their purifier series represents another critical component, designed specifically for integrated wheat flour mill production lines to ensure thorough separation of bran particles from endosperm flour. Beyond wheat-specific equipment, the company provides solutions for processing related grains and byproducts, such as the SH Rice Bran Separation Circular Sifter that efficiently separates granular rice bran materials—demonstrating the versatility of their engineering expertise across multiple grain processing applications.

The international reach of Wuxi Hasen wheat mills is evidenced by their diverse customer base and successful project implementations across multiple continents. Their turnkey approach to integrated wheat flour mill production lines has enabled clients worldwide to establish or upgrade efficient processing facilities. For example, the company has implemented substantial projects such as a 750*2 tons per day wheat flour mill production line—a massive operation capable of processing 1,500 tons daily—demonstrating their capability to handle industrial-scale requirements. Similarly, their expertise extends to other cereal processing, as shown by their 240 tons per day maize flour mill production line in Zambia and 150 tons maize flour mill processing plant in Chengdu.

These successful implementations highlight the adaptability of Wuxi Hasen wheat mills solutions to different regional requirements, raw material characteristics, and production scales. Beyond equipment supply, the company's comprehensive service model includes customized proposals for cereal processing, covering maize milling plants, rice milling plants, buckwheat processing, and more. Their exhibition participation at major industry events like the Zhengzhou Grain and Oil Exhibition further demonstrates their commitment to staying at the forefront of milling technology and maintaining direct engagement with the global grain processing community.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000