Guidelines for Process Adjustments in Wheat Processing Plants During Summer and Autumn

Edited by: www.immyhitech.com /www.immy.cn

I. Introduction:

Understanding the Challenges of Seasonal Transitions Summer brings high temperatures and humidity, while autumn gradually transitions to cooler, drier conditions.

This shift impacts wheat processing in multiple ways: 1. Changes in raw material properties: Wheat stored since summer undergoes internal moisture redistribution as it seeks equilibrium with ambient humidity.

As autumn arrives and air humidity drops, wheat kernels may become harder and more brittle. However, if they absorbed moisture earlier, their husk toughness may increase.

These changes directly affect milling difficulty, flour yield, and the ash content and whiteness of the flour.

2. Changes in processing environment: Lower workshop temperatures and humidity affect equipment performance (e.g., transmission efficiency, sifting effectiveness), pneumatic conveying stability, and operator comfort.

3. Changes in Microbial Activity: Lower temperature and humidity suppress the activity of harmful organisms like mold and pests. However, they may also alter the activity of wheat's own enzyme systems, affecting the biochemical properties of the flour.

Therefore, the core of process and operational adjustments lies in proactively adapting to these changes and reestablishing the optimal balance between personnel, machinery, and materials.

II. Adjustment Strategies for Core Process Systems

(1) Raw Material Management and Pretreatment Section

Raw Material Monitoring and Wheat Blending: - Enhance incoming wheat inspection: Conduct multiple daily checks of key indicators like moisture content, bulk density, and hardness for mill-bound wheat. Summer wheat may be softer with higher moisture, while autumn wheat tends harder with lower moisture. Dynamically adjust blending formulas based on real-time data.

Adjust grain blending strategy: If autumn raw materials are generally hard with low moisture, incorporate some softer or slightly moister wheat to balance overall processing characteristics, preventing sudden yield drops and excessive equipment load.

Watering and Grain Moistening: This is the most critical seasonal adjustment. Adjust watering volume: Autumn's dry air causes rapid surface moisture evaporation in wheat, potentially slowing water penetration. Therefore, total water addition should be finely adjusted based on actual milling moisture measurements. Typically, a slight increase (e.g., 0.2%-0.5%) compared to summer may be required to ensure optimal milling moisture (generally 15.5%-16.5% for hard wheat and 14.5%-15.5% for soft wheat). Avoid insufficient moisture, which can cause brittle bran, increased bran particles in flour, and elevated ash content. Soaking Time Adjustment: Lower temperatures slow water penetration into grains.

Extend soaking time appropriately—typically by 2–8 hours—determined by assessing “sensory indicators” (crisp bite, smooth texture when squeezed) and instrumental testing. Ensure uniform moisture distribution within the grain, soften the endosperm, reduce energy consumption, and improve flour yield. Control the wheat soaking environment: Maintain relatively constant temperature and humidity in the soaking silo to minimize external fluctuations. Where feasible, fine-tune the soaking workshop to prevent excessive drying.

(2) Flour Milling Section

Grinding System:

Gap Adjustment:

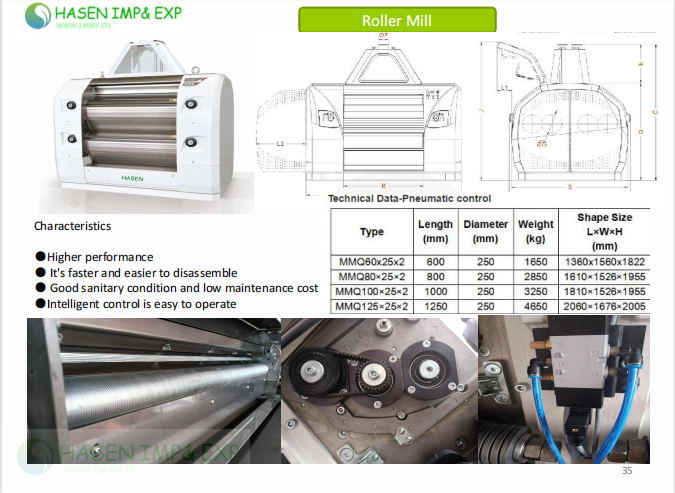

Autumn wheat typically exhibits increased hardness, requiring greater crushing force. The gap between the front-end skin mill and the middle-end core mill should be appropriately tightened to ensure effective shearing and compression of the material. However, note that if wheat becomes excessively hard due to poor prior management, overly tight gaps may cause increased equipment current, accelerated roller wear, and excessive heat generation that compromises flour quality. Therefore, adjustments should follow the principle of “gradual progression, monitoring current, and inspecting material.”

Flow Control:

Hard wheat may exhibit better flowability than soft wheat, but its material properties change after crushing. Monitor material distribution across systems to ensure balanced flow and prevent blockages or stoppages.

Screen Configuration:

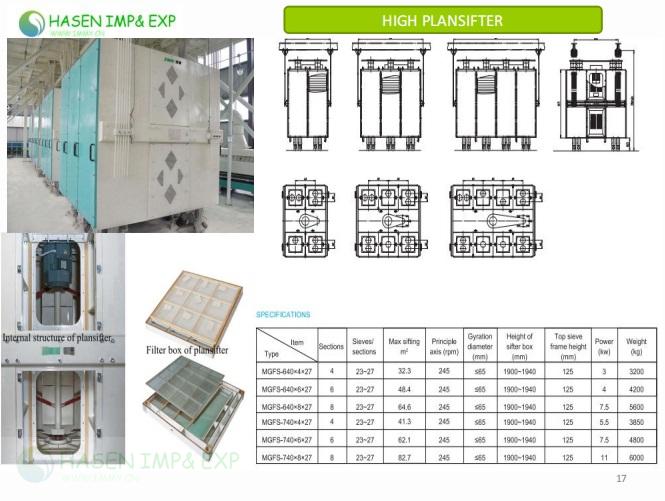

Bran Milling System: As bran may become brittle, consider increasing the mesh density of the pre-bran mill leveling screens to enhance bran purification and prevent excessive breakage from introducing bran particles into the flour.

Core Milling System:

Monitor the quality and quantity of bran cores and wheat kernels. Adjust the flat screen mesh based on particle size distribution and material quality to ensure purity of premium flour. Autumn may yield more abundant, finer-quality wheat kernels, necessitating optimization of extraction pathways.

Cleaning System:

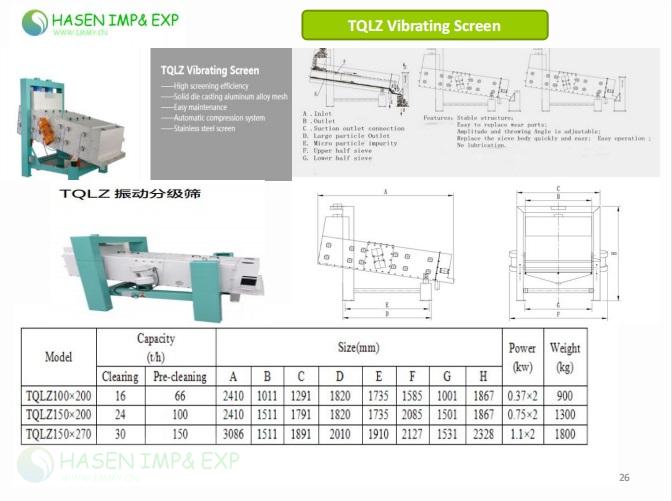

The role of the cleaning machine becomes particularly critical at this stage. Due to increased bran brittleness, the cleaning machine must more precisely separate endosperm adhering to bran flakes and remove fine bran particles mixed into the bran core material. Airflow Adjustment: Autumn air density increases, potentially slightly boosting airflow at the same fan speed.

Check and fine-tune the air dampers on each flour cleaner to ensure stable negative pressure within the suction hood, effectively drawing away lightweight bran without carrying heavy endosperm particles.

Screens and Vibration Amplitude: Depending on incoming material conditions, adjustments to screen configurations and vibration amplitude on flour cleaners may be necessary to achieve optimal particle size grading and purity enhancement. (3) Product Handling and Downstream Processes

Flour Collection and Blending: Seasonal variations may cause slight changes in ash content, whiteness, protein quality, and other indicators across different milling systems. Strengthen online monitoring at each flour collection point and conduct laboratory analysis of final products.

Timely adjustments to flour collection and blending schemes must be made to ensure final products meet established standards. For instance, if ash content slightly increases in the main mill's output, blending ratios may require adjustment or stricter control over upstream material purity.

Packaging and Storage:

Autumn's dry air reduces flour caking during packaging and storage, but static electricity may intensify, affecting packaging and palletizing. Verify that static elimination devices on packaging machines are functioning properly. Maintain cleanliness and dryness in the finished goods warehouse. Although the risk of mold growth is reduced, prevent external moisture from entering.

III. Strengthening Operational Procedures and Management Focus Areas

Enhance Patrol Inspections and Equipment Checks: Increase inspection frequency for key equipment (e.g., grinding mills, flat screens, flour cleaners, fans), focusing on bearing temperatures, equipment vibration, current fluctuations, etc., to promptly identify abnormalities caused by changes in material properties.

Inspect pneumatic conveying pipelines to ensure no air leaks or blockages, maintaining conveying efficiency.

Data-Driven Precision Operations: Enhance recording and trend analysis of critical process parameters (e.g., milling moisture content, system flow rates, flour yield, electricity consumption per ton of flour). Use data comparisons to scientifically guide adjustments rather than relying solely on experience.

Implement an incremental “small steps, quick runs” fine-tuning approach.

Observe the effects of any adjustment for a period to avoid production fluctuations caused by drastic changes.

Temperature and Humidity Monitoring with Environmental Management: Install thermohygrometers in critical workshop areas (e.g., wheat soaking room, milling floor, flat screen floor) and record readings regularly.

Factories with the capability may consider using central air conditioning or industrial humidification/dehumidification equipment to maintain a relatively stable workshop environment (e.g., temperature 22-26°C, humidity 60%-65%). This significantly mitigates the impact of seasonal changes.

Personnel Training and Awareness Enhancement: Organize training sessions for operators on seasonal adjustment protocols, ensuring they understand the underlying principles to enhance sensitivity and proactivity in responding to changes.

Emphasize interdepartmental coordination to ensure seamless alignment throughout the entire process—from raw material reception to finished product storage.

IV. Conclusion The transition period between summer and autumn presents both challenges and opportunities for wheat processing plants. The challenge lies in disrupting established production equilibrium; the opportunity arises from leveraging precision adjustments to unlock equipment potential, optimize processes, and enhance adaptability to complex raw materials while stabilizing product quality.

Success hinges on “anticipation, monitoring, fine-tuning, and coordination.” By implementing these systematic process and operational adjustments, production transitions smoothly, effectively mitigating seasonal disruptions. This ensures consistent output of high-quality products, maximizing economic benefits for the facility.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000