-Styrene Butadiene Rubber for Chewing Gum and Bubble Gum Applications

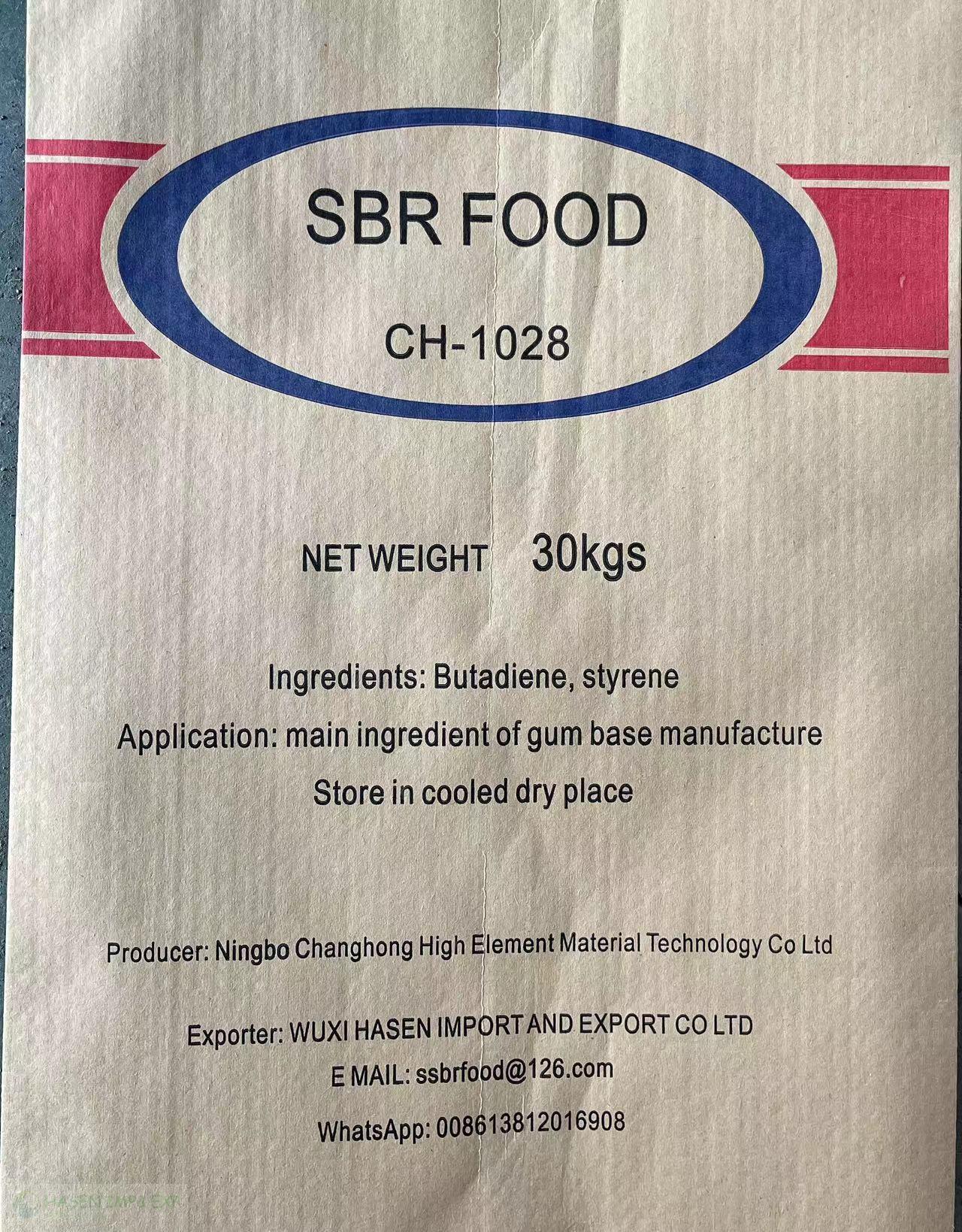

-High-Quality SBR Rubber Food from Wuxi Hasen China

Edited by: www.immyhitech.com

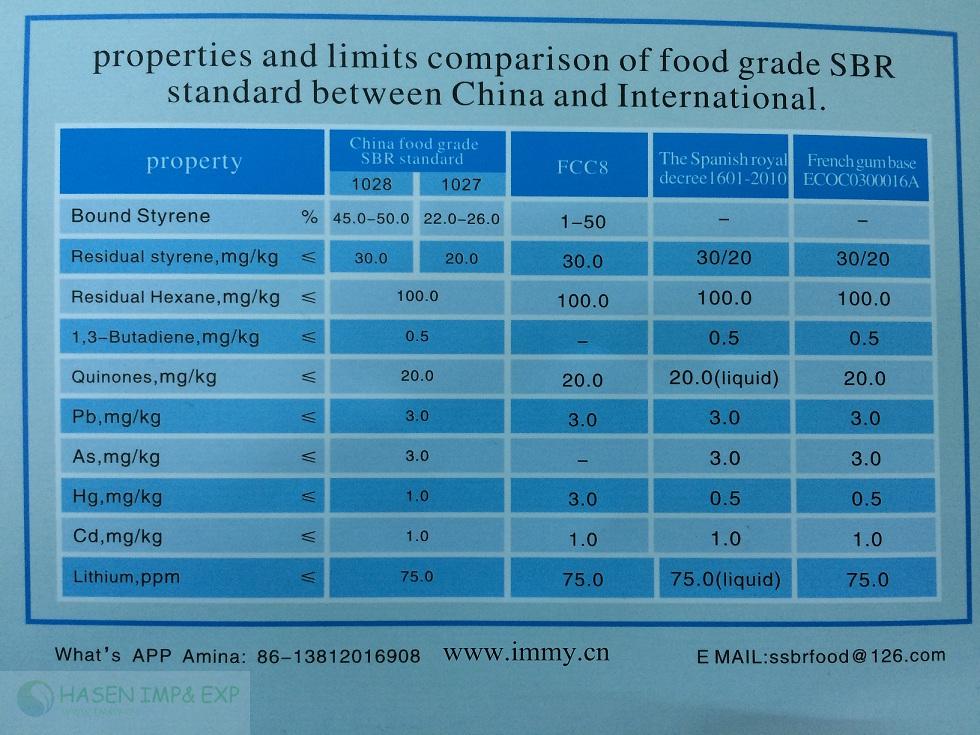

SBR rubber food (Styrene Butadiene Rubber for chew gum and bubble gum industry) is widely used as a safe and reliable base material in the confectionery and candy sector, especially for chewing gum and bubble gum formulations. Produced under strict quality control, SBR rubber food (Styrene Butadiene Rubber for chew gum and bubble gum industry) offers excellent elasticity, stability, and processability to meet international food-grade standards.

As a trusted supplier, Wuxi Hasen China provides consistent and compliant SBR rubber food (Styrene Butadiene Rubber for chew gum and bubble gum industry) tailored for modern food applications and global markets Wuxi Hasen :www.immyhitech.com

SBR FOOD rubber (for chew gum and bubble gum industry) is widely used in food applications requiring extreme temperature resistance and flexibility.

SBR has stronger abrasion resistance

SBR FOOD rubber (for chew gum and bubble gum industry) can handles much higher temperatures

SBR is more economical for standard food environments

Each material serves a different purpose, and the best choice depends on application requirements.

Selecting the right food grade rubber often involves comparison between multiple elastomers.

Food grade EPDM rubber is known for excellent resistance to heat, steam, and weathering. Compared to SBR:

EPDM performs better at higher temperatures

SBR offers superior abrasion resistance

SBR is often more cost-effective

SBR is typically preferred for mechanically demanding applications, while EPDM is chosen for thermal and steam exposure.

Silicone rubber is widely used in food applications requiring extreme temperature resistance and flexibility. Compared to silicone:

SBR has stronger abrasion resistance

Silicone handles much higher temperatures

SBR is more economical for standard food environments

Each material serves a different purpose, and the best choice depends on application requirements.

When selecting a food grade rubber material, consider:

Type of food contact (direct or indirect)

Operating temperature range

Mechanical stress and abrasion

Cleaning and sanitation processes

Cost-performance balance

Food grade SBR rubber remains a practical and reliable choice for many food contact applications where durability and safety are equally important.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000