Secondary Water Wddition and Wecondary Wetting in Wheat Processing: Differences and Effects

Edited by: www.immyhitech.com www.immy.cn

(FLOW BALANCE)

In the process of wheat processing, moisture adjustment is a key step, which directly affects the quality and yield of flour. Among them, the second addition of water and the second wetting wheat are two commonly used moisture adjustment methods, although the purpose is the same, but the mode of operation and the effect is different.

I. Secondary water addition

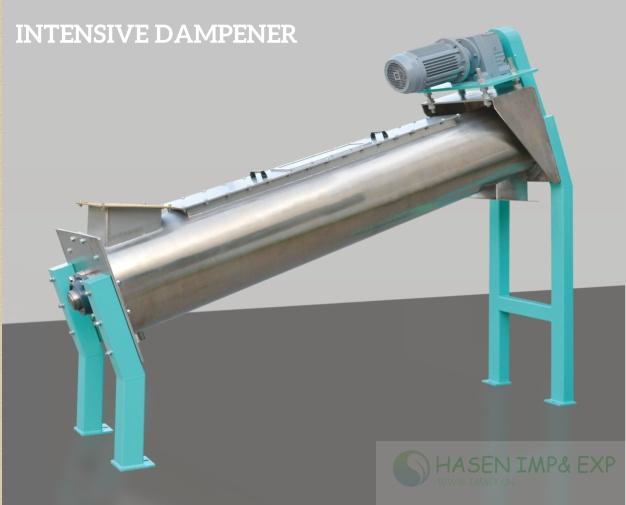

1. Definition: Secondary water addition refers to adding the right amount of water to the wheat again according to the moisture and processing needs of wheat after the first moistening. 2.

2. Operation: usually in the wetting bin or wetting machine, through the water spray device evenly sprayed to ensure full penetration of water.

3. Function: Supplementary moisture: After the first moistening, some of the wheat may not be adequately moistened, and a second addition of water ensures that all the wheat reaches the desired moisture content.

Improve processing performance: Proper moisture adjustment can soften the endosperm, reduce the hardness, facilitate grinding and improve the flour yield.

Stabilise flour quality: Moisture adjustment helps to reduce flour ash and improve colour and taste.

4. Cautions:

Control the amount of water: too much will cause the wheat to be sticky, too little will not achieve the effect, need to be adjusted according to the actual situation.

Uniformity of adding water: Make sure the water is evenly distributed, avoid local over-wet or over-dry.

Dampening time: After adding water, it is necessary to extend the dampening time so that the water can fully penetrate.

Second rinsing

1. Definition: secondary moistening is in a moistening wheat, wheat again into the moistening bin, after a certain period of time, so that the moisture to further penetrate. 2.

2. operation: a wetting of wheat after the wheat re-fed into the wetting bin, standing for a few hours to more than ten hours.

3. effect:

Promote water penetration: prolong the moistening time, so that the water penetrates into the wheat more evenly.

Improvement of endosperm structure: prolonged moistening softens the endosperm, reduces hardness and improves flour yield.

Improve the quality of flour: secondary moistening helps to reduce the ash content and improve the colour and taste of flour.

4. Caution:

Dampening time control: too long may lead to heat and deterioration of wheat, too short is not effective, need to be adjusted according to the actual situation.

Temperature control: The temperature of moistening bin should be suitable, too high may lead to wheat deterioration.

Ventilation: Keep the wetting bin ventilated to prevent the wheat from heating.

Third, the difference between secondary water and secondary wetting wheat

Mode of operation: secondary watering through the water spray device, the second wetting wheat is static.

Time: the secondary water time is shorter, the secondary wetting time is longer.

Effect:

Secondary watering is mainly used to replenish water, while secondary wetting pays more attention to water penetration and endosperm structure improvement.

Fourth, production guidance recommendations

According to the quality of wheat and processing needs to choose the appropriate water adjustment method.

Strictly control the amount of water and wetting time to ensure the effect of moisture adjustment.

Regularly check the temperature and ventilation of the wetting bin to prevent wheat deterioration.

Through the reasonable use of secondary water addition and secondary wetting, wheat processing efficiency and flour quality can be effectively improved.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000