Steam-Pre Cooked Flake Machine for corn oats other grains&oil seeds,animal feed line. Steam Flaking – Focus on Conditioning Steam flaking of cereal grains such as corn, barley, sorghum, and wheat for beef cattle improves feed conversion and animal growth. www.immy.cn / www.immyhitech.com

PRE COOKED FLAKING MACHINE

STEAM FLAKE MACHINE FOR CORN OATS GRAINS

TURNKEY PROJECT PROVIDER

STEAM (PRE COOKED) FLAKE MACHINE FOR CORN OATS Steam Flaking – Focus on Conditioning Steam flaking of cereal grains such as corn, barley, sorghum, and wheat for beef cattle improves feed conversion and animal growth.

PRE COOKED FLAKING MACHINE

STEAM FLAKE MACHINE FOR CORN OATS GRAINS

TURNKEY PROJECT PROVIDER

. www.immy.cn / www.immyhitech.com

Steam flaking also improves starch digestion and lactation performance in dairy cows. In many locations around the country but especially in the Southwest and on the West coast, feed lots and feed mills supplying dairies are seeing the benefits of consolidating several smaller flaking units into one, two, or three larger machines.

The advantages of fewer larger machines include reduced maintenance and operating costs, more efficient utilization of existing space, and increased capacity and product quality.

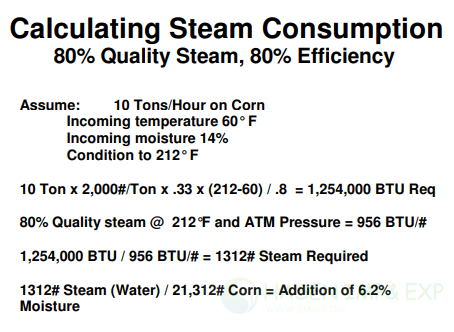

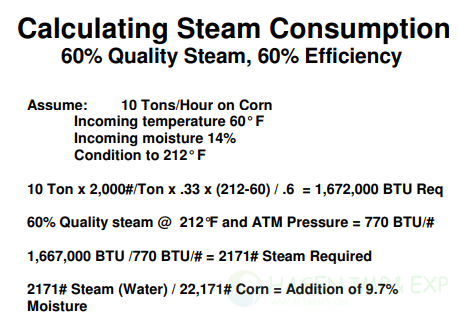

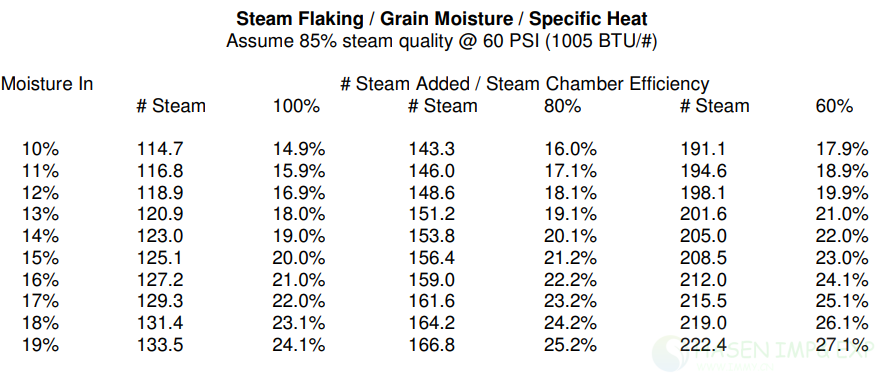

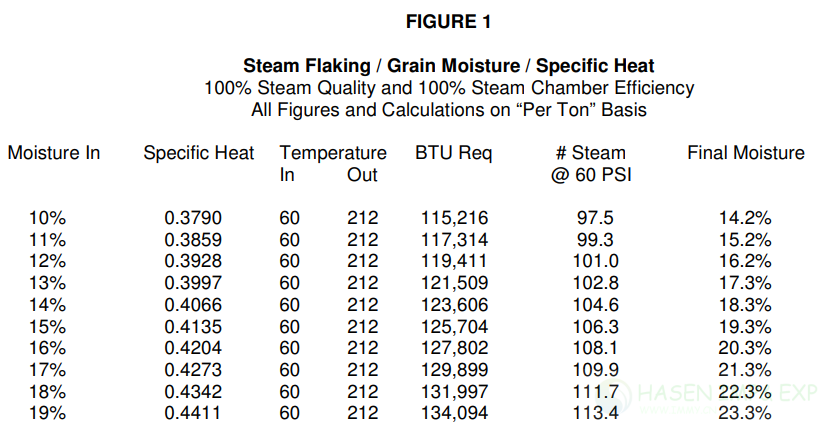

Conditioning for steam flaking requires time, temperature, and moisture. Ordinarily the temperature and moisture are provided by steam, and the time is provided by a relatively large vessel commonly referred to as a steam chamber, steam chest, or steamer. As the capacity of steam flaking systems increase, the size of the conditioners must increase to provide adequate retention time for the temperature and moisture to fully penetrate each kernel of grain.

While years ago retention times of 12 to 15 minutes were considered adequate, many of today’s processors are employing steam chambers sized to produce retention times of 60 minutes or more. As the capacity of some steam flaking lines approach 30 tons per hour, the size of the steam chambers become remarkably large!

![]()

1. This complete set of equipment is processing and producing refined mature low-fat corn flour with corn as

raw material

2. Using advanced processing technology, peeling, germ removal, steaming, flaking, milling and co-production

processing, it is a low-fat corn flour.

The complete set of equipment is including five parts:

Raw grain cleaning: magnetic separation-sieving-winnowing-stone removal -watering-moistening grain

Peeling and degerming part: Magnetic separation-peeling -degerming

Flaking : Soaking-steaming-flaking-drying and cooling

Milling part: sla breaking-grading-milling-finished product packaging

Feed part: collection-crushing-finished product packaging

3. Main supporting equipment:

Bucket elevator, scraper conveyor, self-balancing vibrating screen, vertical suction duct, grading destoner, suction destoner, fan, water mixer,

corn peeling machine, corn degerming machine, steaming tower , flaking machine, drying cooling box, vibration suction duct, ballast breaking

machine, milling machine, high square screen, packing scale, etc.

4. Steel frame structure, low power consumption, fine workmanship of steel frame platform, elegant appearance.

5. Compact structure, easy installation and operation.

6. Product structure: one kind of corn flour, one kind of corn feed

7. Production capacity: The output of the cleaning section and peeling section of this process is 100_200T/24h of corn, and the extraction rate of peeling and germination is 25%-32%. The degree of peeling can be adjusted according to the actual situation.

PRE COOKED FLAKING MACHINE

STEAM FLAKE MACHINE FOR CORN OATS GRAINS

TURNKEY PROJECT PROVIDER

Calories 120

Total fat 1g - 1%

cholesterol 0g - 0%

Na 0g - 0%

total carbohydrates 20g - 7%

Dietary fiber 3g - 10%

Total suger 0g - 0%

Contains 0g added sugar 0%

Protein 3g

Vitamins D 0%

Ca 0%

Fe 2mg - 8%

K 65mg - 2%

*The percentage of Daily Value tells you how much of the nutrient in a serving contributes to your daily diet. advice 2000 calories per day for general nutrition.

Not a significant source of cholesterol, sugar, vitamin A, vitamin C and Ca

Ingredients: Enriched with Precooked White Cornmeal (Niacin, Iron, Roboflavin, Tiamin and Folic Acid). May contain traces of soy.

Versatile Features

Arepa's characteristics vary by color, flavor, size and the food they are stuffed with. Versatility is without a doubt arepa's best quality, and thanks to the dish's simplicity and subtle taste, it can be adapted to any recipe.

Arepas can be prepared and filled with anything you like including: beef, pork, chicken, duck, turkey, tuna, salmon (or any other fish), shrimp, seafood, salami, ham, cheese, eggs, beans , vegetables, etc. Arepas can be served for breakfast, lunch, snack or dinner and are also a very convenient meal that makes you eat quickly, warm, tasty and healthy!

PRE COOKED FLAKING MACHINE

STEAM FLAKE MACHINE FOR CORN OATS GRAINS

TURNKEY PROJECT PROVIDER

STEAM FLAKE MACHINE FOR CORN OATS - TURNKEY PROJECT PROVIDER

PRE COOKED FLAKING MACHINE

STEAM FLAKE MACHINE FOR CORN OATS GRAINS

TURNKEY PROJECT PROVIDER

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000