Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed. www.immyhitech.com

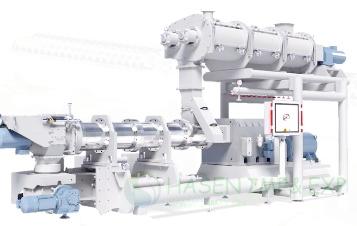

HasenSingle screw extruder machine is a classic extruding equipment, through the screw and cylinder friction on the material to form the material promotion,

extrusion, simple structure, stable running, with the lowest running costs to produce high quality feed. The whole machine is composed of anti-arching accurate

feeding system, DDC double-axis differential conditioning system, steam and liquid adding system, extruding system etc, which is one of the most stable

extruding technology on the market.

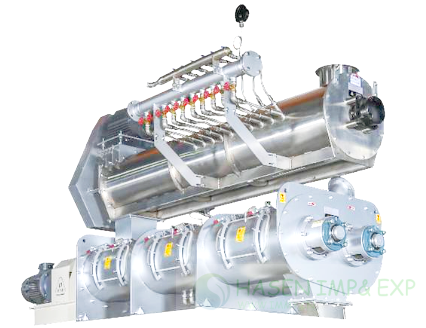

Hasen Twin-screw extruder screw section is "8" shape, the promotion and extruding of the material are completed between the two screws through the meshing

and separation movement of the two screws, the material is not easy to bond, not easy to produce countercurrent, generally can be adjusted screw speed according

to the characteristics of the material during processing. The twin-screw extruder has the advantages of strong adaptability, sliding transport and self-cleaning,

It is generally used in the production of aquatic feed with high added value and high fat, also used in the production of pet food containing high meat pulp or fresh meat.

FAQ:

1. What is a screw extruder in an aquatic feed production line?

A screw extruder is a core processing machine used in aquatic feed manufacturing, where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed is the primary function. In modern feed mills, Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed by applying precise temperature, pressure, and shear force. This allows feed producers to manufacture floating, slow-sinking, or sinking pellets using one flexible system where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed efficiently.

2. How does a screw extruder control feed density?

The ability of Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed depends on screw configuration, barrel temperature, moisture level, and die structure. By adjusting these parameters, Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed through controlled expansion or compaction. In professional animal feed mill machine systems, Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed without changing raw materials.

3. What is the difference between floating and sinking aquatic feed?

Floating feed requires higher expansion, while sinking feed requires higher density, and this is exactly where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed plays a critical role. Through mechanical and thermal control, Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed to meet the feeding habits of fish, shrimp, and aquatic species. With one extruder, Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed for multiple applications.

4. Why is density control important in aquatic feed?

Density affects feeding efficiency, water pollution, and feed conversion ratio, which is why Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed is essential. If feed density is incorrect, nutrition loss increases, but when Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed, pellets remain stable in water. Professional feed producers rely on systems where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed accurately.

5. Can one screw extruder produce both sinking and floating feed?

Yes, a single advanced extruder can do both, because Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed by adjusting operational parameters. In modern animal feed mill machine design, Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed without replacing major components. This flexibility allows manufacturers to respond quickly to market demand where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed.

6. What materials can be processed by a screw extruder?

Corn, soybean meal, wheat, fish meal, and protein concentrates are commonly used, and Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed regardless of formulation. With precise control, Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed even when raw material ratios change. This adaptability ensures Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed in commercial feed mills.

7. How does moisture and temperature affect density control?

Moisture and temperature directly impact starch gelatinization, which is why Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed through thermal regulation. Higher moisture and temperature increase expansion, while lower settings help Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed with compact structure. Advanced systems ensure Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed consistently.

8. Is screw extruder technology suitable for shrimp and fish feed?

Yes, shrimp and fish feed have different sinking speeds, and Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed to match species behavior. Whether slow-sinking shrimp pellets or floating fish feed, Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed precisely. This makes the screw extruder an essential animal feed mill machine where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed.

9. What are the advantages of using a screw extruder for density control?

The biggest advantage is flexibility, because Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed with one machine. Energy efficiency, stable pellet quality, and reduced waste are achieved when Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed accurately. Feed mills benefit from automation where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed consistently.

10. How does screw design influence feed density?

Screw pitch, compression ratio, and length directly affect pressure buildup, so Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed by mechanical design. Customized screw configurations allow Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed for different formulas. This engineering ensures Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed reliably in continuous production.

11. Is density control automated in modern extruders?

Yes, modern control systems monitor temperature, torque, and moisture, ensuring Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed automatically. PLC systems help operators fine-tune parameters so Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed with minimal manual intervention. Automation guarantees Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed in large-scale feed mills.

12. Where can I buy a reliable screw extruder for aquatic feed?

If you are looking for a professional animal feed mill machine where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed, choosing an experienced manufacturer is critical. With proven engineering and export experience, WUXI HASEN provides advanced systems where Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed for global markets.

For product consultation, technical support, and customized solutions of Screw Extruder Control the density of finished products according to different requirements, suitable for sinking or floating aquatic feed, please contact WUXI HASEN via www.immyhitech.com

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000