Application of bearing temperature detection and

intelligent lubrication system in wheat processing-1

Edit By: www.immy.cn www.immyhitech.com

.png)

After the long-term production exploration and practice of wheat milling process, on the basis of analyzing the reasons for the low efficiency of traditional manual equipment inspection and maintenance, a bearing temperature detection and automatic lubrication system based on PLC control was proposed, which could ensure the long-term stable operation of the equipment and improve the economic benefits of milling enterprises.

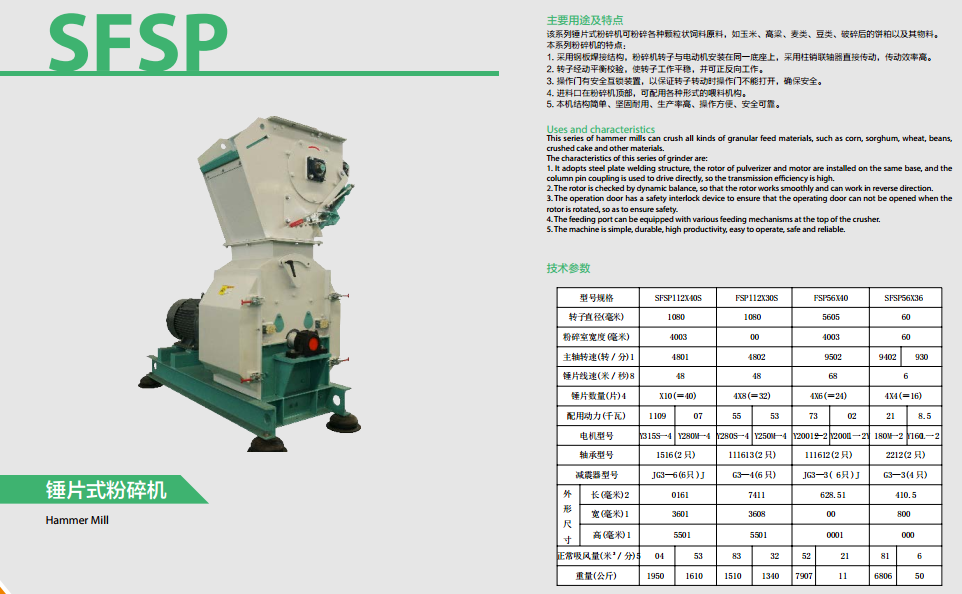

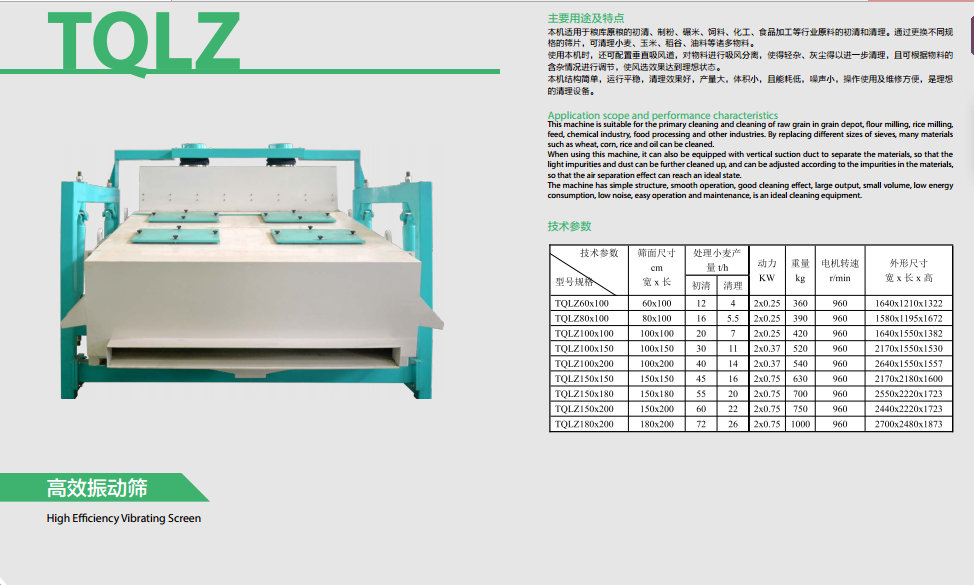

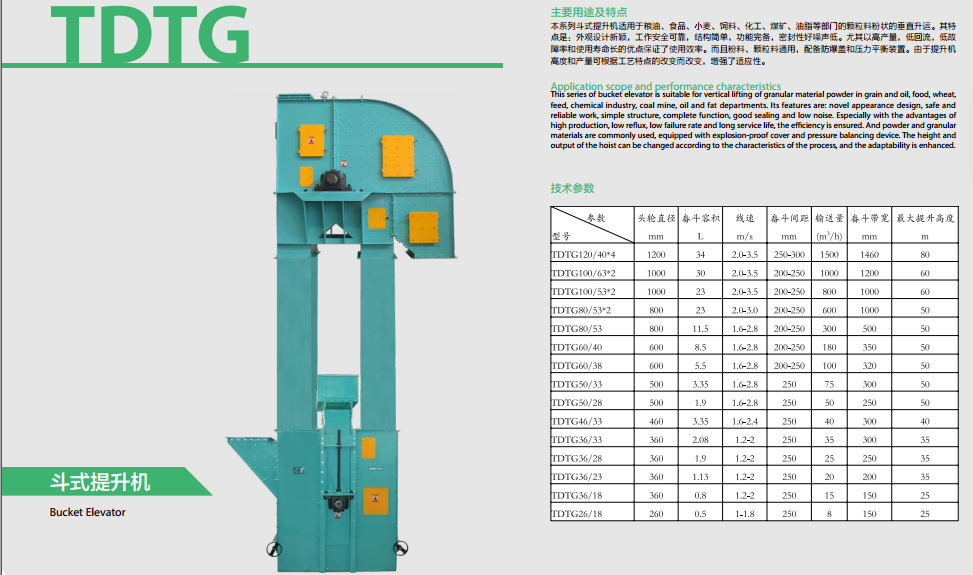

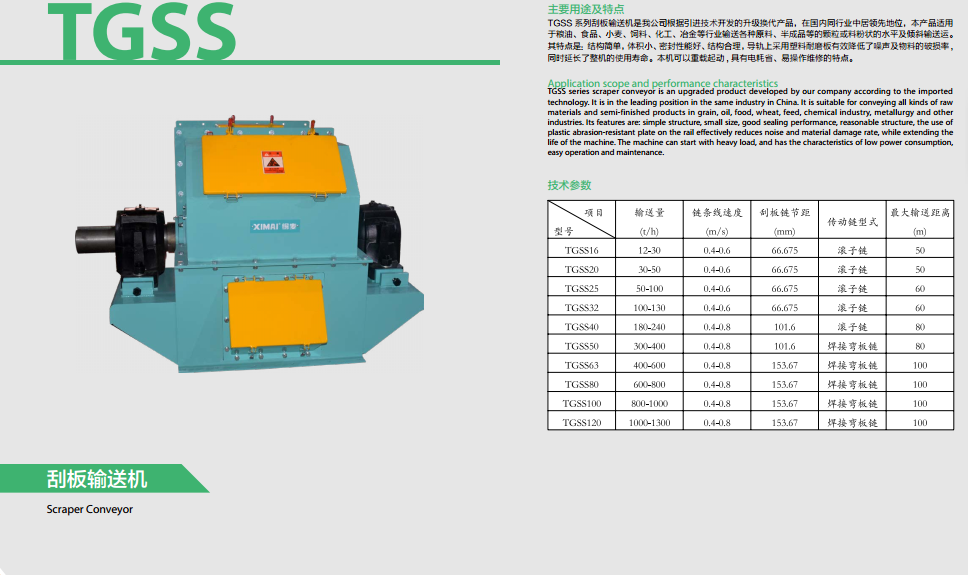

The wheat processing industry has a long process flow, a wide variety of equipment, and a variety of equipment transmission methods, some of which also carry more than 100 kW drive motors. The main equipment is high-pressure fan, mill, high square screen, scraper, hoist, threshing machine, mill, mixer, inspection screen, roots fan and other equipment and motors, and wheat flour processing plant in order to give full play to the continuous production and good economic benefits often use 24 hours of non-stop production, so to ensure the good operation of the equipment transmission parts in order to ensure the good process performance of the equipment, so as to ensure the stability of product quality, so the planned maintenance and maintenance of equipment need to be scientifically arranged.

According to statistics, nearly 7% of rotating machinery failures are caused by rolling bearing failures, and 30% of the total mechanical equipment failures are caused by rolling bearing failures [1]. Unplanned shutdowns, load shedding operations, replacement of equipment or spare parts caused by rolling bearing failures of machinery and equipment will have a great impact on the economic efficiency of flour enterprises. If the equipment can be maintained scientifically and reasonably, and give full play to the due process performance of the equipment, the stability of production can be guaranteed.Efficient operation, and at the same time can bring good production efficiency and operating benefits to the enterprise.

For more information please check: BEARING IN FLOUR POWER: Flour power - Evolution (skf.com)

The main reason for the failure of rolling bearings in rotating machinery equipment is that the bearing temperature is too high during the operation of the equipment. Excessive bearing temperature is a common and harmful fault of rotating equipment, which can lead to the reduction of the service life of the bearing, cause the bearing seal to rupture, the grease to be air-dried, and eventually lead to equipment failure, and even cause dust explosion in some specific areas, which seriously affects the normal operation of the enterprise.

Based on the analysis of the actual operation of the enterprise and the experience and experience of various industries, this paper proposes a set of design scheme for the bearing temperature detection and intelligent lubrication system based on PLC control suitable for the wheat processing industry, in order to solve the problem that the failure of equipment bearings affects the normal operation and production of enterprises.

Analysis of the causes of high bearing temperature

Common causes of high bearing temperatures are as follows:

(1) Reasons for lubrication: (1) Bearing grease is injected too much, due to the low heat transfer efficiency of the grease, resulting in poor heat dissipation of the bearing; (2) Lack of oil in the bearing. Insufficient oil supply or interruption of oil supply leads to dry friction heating, and the bearing will be burned if not found in time; (3) Deterioration of oil. Failure to change the oil regularly, emulsification of the oil inlet or poor sealing into the dust will lead to oil deterioration; (4) The oil brand and model are wrong, and different oil products are mixed with each other.

(2) Causes of mechanical vibration:

(1) Vibration caused by poor concentricity of coupling;

(2) Poor dynamic balance of rotating parts or poor installation and alignment, resulting in vibration or uneven load;

(3) Vibration caused by insufficient stiffness of the bearing base;

(4) Vibration caused by loose bolts.

(3) Assembly reasons:

(1) The bearing clearance is too small (such as the grinding roller bearing), and the rolling element and the inner and outer rings produce large contact stress;

(2) The outer ring of the bearing is pressed too tightly to deform it, resulting in excessive friction torque;

(3) The bearing installation is skewed;

(4) The parts around the bearing rub against each other, heat or even smoke;

(5) The V-belt assembly is too tight, and the directional load of the bearing is too heavy (such as grinding rollers, high square screens, etc.).

.png?x-oss-process=image/resize,w_100/quality,q_100)

(4) Environmental factors: the indoor space is small and not ventilated, and the summer is hot and high.

(5) Operation reasons: due to the one-sided pursuit of output, the load is increased, and the bearing is overloaded.

(6) Bearing failure: cracks in the inner and outer rings of the bearing, excessive wear of the cage, clearance exceeding the limit of wear limit, and serious defects such as rolling element crossing.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000