Feb 05, 2024

Craft | How to realize the multi-point unloading and warehousing of bulk grain silos?

Prepared by: www.immy.cn

Bulk grain silos are one of the mainstream choices for large-scale grain storage, which has high transfer efficiency, fast entry and exit and high degree of automation. The horizontal conveying of bulk grain mainly includes scraper conveyor, air cushion conveyor, single idler belt conveyor, and three-idler belt conveyor

(see: bulk grain horizontal conveying equipment).

In addition, there is also pneumatic pipeline type conveying mode, which is better than mechanical conveying, natural airtightness, light structure, greatly simplifies the warehousing process, but the deficiency lies in the limitation of conveying capacity, high energy consumption, and the defect of noise, which restricts its application in large-volume conveying engineering. The selection of equipment and process forms for the entry and exit of bulk grain silos is also based on the characteristics of the above-mentioned equipment, and scientific and reasonable selection is carried out. Silos are generally set up in groups, so the silo top should have the basic requirements of multi-point unloading.

The buried scraper conveyor scraper conveyor can realize multi-point unloading in the middle (discharge gate and chute are set at the top of each silo) and flexible distribution; the equipment has good airtightness, good operating environment, small size, light weight, narrow conveying trestle, small output, and less investment.

However, when the scraper conveyor is discharged in the middle, the material may not be clean, and the return device needs to be set up in the machine head; the power of the equipment is larger, the energy consumption is large, and it is not suitable for long-distance transportation; the scraper, the chain and the bottom plate of the machine groove are worn out greatly, and they need to be maintained and replaced regularly; the grain is broken greatly, and it is not suitable for the storage and transportation of easily broken grain varieties; the failure rate of the scraper conveyor is high.

Air cushion conveyor Air cushion belt conveyor has the characteristics of stable operation, large conveying capacity, small running resistance, small driving power, full ability to meet the requirements of self-enclosure, good operating environment, mature technology, reliable performance, low failure rate and low maintenance cost.

However, the air cushion belt conveyor needs to realize the entry of multiple shallow round silos arranged through lap (only the head can be discharged), and there are the number of motors, There are many control points, and the head of each belt conveyor needs to be provided with a maintenance platform, the maintenance is inconvenient, the investment is slightly higher, and the overlap causes the grain to be thrown and broken for many times; the conveyor of the whole row of silos needs to be opened at the same time when the end bin enters the warehouse, and the energy consumption is slightly higher; the equipment is under positive pressure, and the sealing is not tight, and it is easy to lead to the dust escape of the conveying process; the climbing angle limit of the air cushion belt conveyor is insufficient, and the lap mode is not suitable for the shallow round silo group with too small spacing.

Single idler belt conveyor and triple idler belt conveyor are both conventional belt conveying methods, the principle is similar, the difference is that the layout form and quantity of the bearing roller are different, and the sealing effect of the former is better.

There are several ways to achieve multi-point unloading in the two:

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)

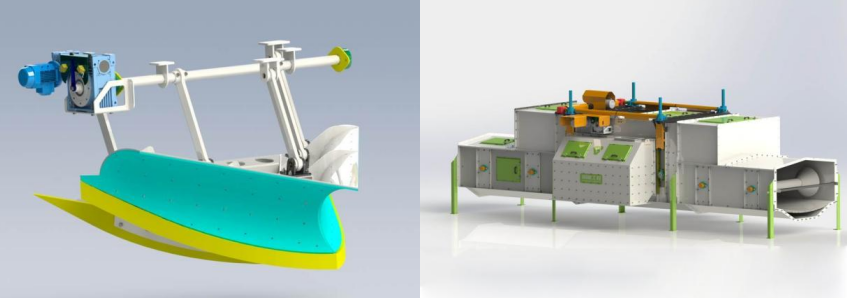

3.1 PLOUGH DISCHARGER (generally double-sided) Plough type multi-point unloading by controlling the lifting of the coulter and the bottom platform of the belt, so that the coulter and the belt produce friction, to achieve the purpose of material distribution and unloading, is a belt conveyor with the top of the bin more commonly used at present.

SINGLE IDLER CONVEYOR PLOW DISCHARGER

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000