Innovative Process Technology - Low-Fat CornstarchIinto Various Types Of Syrups

-New process of dry separation of corn for sugar production, revolutionising corn processing

Edited by (www.immyhitech.com / www.immy.cn )

With the increasing demand and requirements for food, medicine, biology, fermentation and other industries, corn processing has entered the fast track of industrial development.

After years of research and experimentation, we have jointly developed a new process of dry separation of corn and sugar production from low-fat corn flour, which has been successfully applied in large-scale industrial production. Corn dry separation sugar process grain sugar conversion rate is higher, by-product yield is higher, production and operation costs are reduced, for the deep processing of corn industry technology opens up a new track. (www.immyhitech.com / www.immy.cn)

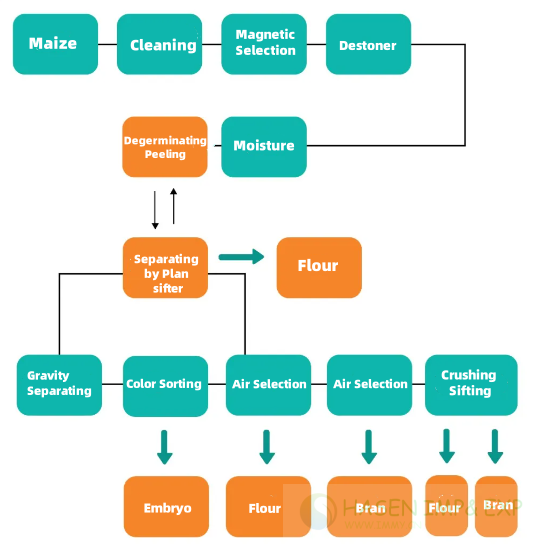

Corn co-production of low-fat cornmeal process

Corn as an important raw material for all kinds of starch sugar (maltose, glucose syrup, crystalline glucose, F55 fructose, etc.), amino acids and fermentation products using glucose as a carbon source, the quality and performance of the special low-fat cornmeal plays a crucial role. (www.imyhitech.com / www.immy.cn)

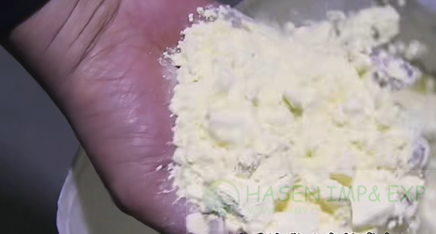

Corn dry separation of sugar production process using low-fat cornmeal as raw material, corn embryo extraction, extraction of skin, low-fat cornmeal co-production process is the domestic advanced new semi-dry corn intelligent production line.

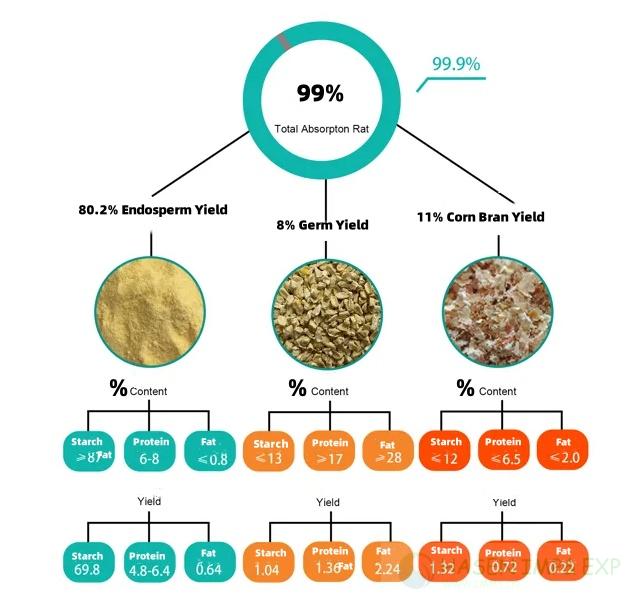

After many tests, the process of embryo extraction rate of 9%, 10% of the skin and miscellaneous yield, can produce 81% of low-fat corn flour, of which the fat content of low-fat corn flour is controlled within 0.8%, ash is controlled within 0.6%, and the starch content of the corn flour is maintained at more than 87%. The physical and chemical indexes meet the requirements of innovative syrup process preparation. (www.imyhitech.com / www.immy.cn)

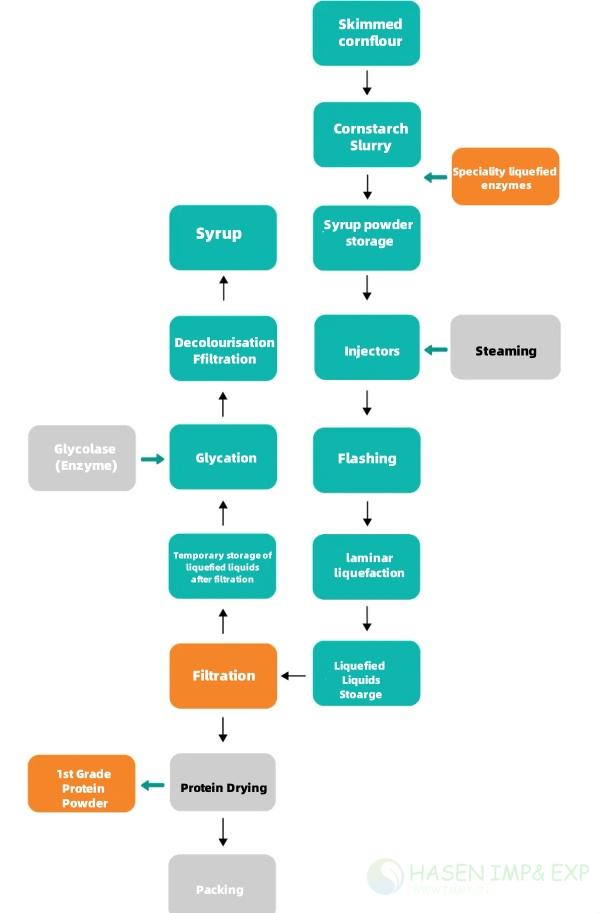

SUGAR PROCESSING

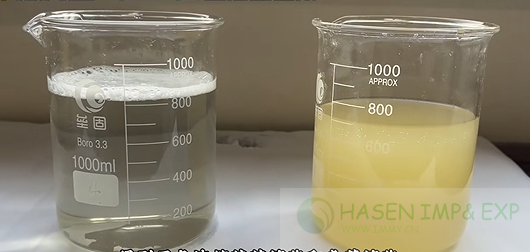

The glucose produced by WUXI HASEN's low-fat cornflour sugar-making process is slightly yellowish in colour, clear, soft in taste, free from harmful substances, and of better quality compared with traditional wet products.

Laboratory measurements show that the output glucose syrup has a concentration of 27%-71%,

a DE value of >98,

a DX value of >95,

a filtered protein dry grade of 9.5%,

a protein content of ≥60%,

and a transmittance rate of ≥98%.

Dry Sugar Process Features High Efficiency: With the innovation of equipment and the improvement of optoelectronic self-control level, the corn dry separation sugar technology is able to convert corn into grape solution within 48 hours, which is about 38 hours shorter than the traditional wet process technology. (www.imyhitech.com / www.immy.cn)

Accuracy: The technology adopts advanced professional equipment, the total corn yield reaches 99.5%, protein yield reaches 9.5%, skin and miscellaneous yield reaches 10.5%, starch utilisation rate reaches 70.5%, germ yield reaches 9.0%, and saccharification DE value is >98% and DX value is >97% or more. Stability: after a long time of testing and verification, the corn dry separation equipment has good stability, can be in the normal workshop environment all year round stable operation, failure rate is less than 2%. (www.imyhitech.com / www.immy.cn)

Flexibility: corn dry separation sugar technology can be customised according to customer's needs, different from the traditional wet process subject to strict state control, green, low energy consumption, to meet customer's individual needs in the field of starch sugar.

Economy: Under the same output, the investment of dry method is greatly reduced, the production and operation cost is only 1/5 of wet method, no low value product corn slurry is produced in the production process, high by-product yield, strong premium ability, no sewage, and the production cost of the product (glucose) can be greatly reduced. (www.imyhitech.com / www.immy.cn)

The new process of corn dry separation sugar production developed by WUX HASEN is a revolutionary, innovative and breakthrough technology. This process is a strong proof of Huayu Wantong's technical strength, a representative of the new quality productivity of the corn deep processing industry, and a model of green and lean production, which will bring new changes and development opportunities for the corn deep processing industry.

Most welcome to discussing with us in professional way in such grain and oil, feed, flaking mill technology and market issues, Lets move forwarding to meet the demand of worlswide market and all ways application.

Hope to be your valued supplier and business partner in Grain&Oil, Feed, Flaking mill fields.

Contact:

Whatsapp/Wechat/Phone :008613812016980

E mail: millmachinecn@gmail.com

www.immyhitech.com / www.immy.cn

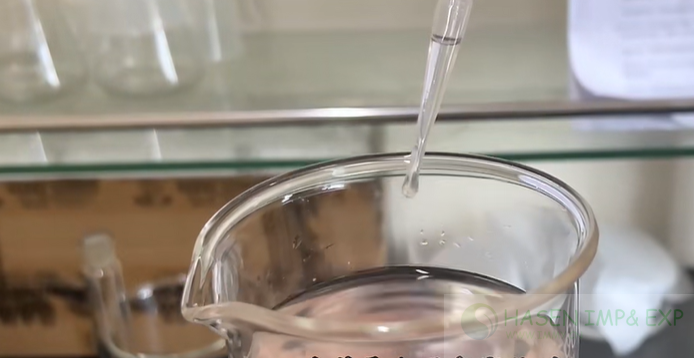

LAB TEST :

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000