Hammer Mill (Water Deop Type Pu;verizer)

-- For normal grinding,suitable for grinding of poultry & livestock feed.

-- Tear-circle grinding chamber,effectively eliminates circumfluence during grinding,high throughput.

-- U-shape second grinding mechanism on the bottom of the grinding chamber, increases product beating frequency,more uniform particle size.

-- Rotor passes accurate balance test,smooth rotating and low noise.

-bioethanol hammer mill

Can process common crush, also process thin and minuteness crush, apply to large and middle type feed factory with high quality feed production;www.immyhitech.com

-- bioethanol hammer mill

-- For normal grinding,suitable for grinding of poultry & livestock feed.

-- Tear-circle grinding chamber,effectively eliminates circumfluence during grinding,high throughput.

-- U-shape second grinding mechanism on the bottom of the grinding chamber, increases product beating frequency,more uniform particle size.

-- Rotor passes accurate balance test,smooth rotating and low noise.

Can process common crush, also process thin and minuteness crush, apply to large and middle type feed factory with high quality feed production; www.immy.cn / www.immyhitech.com

Device Description

-- Ultra-wide multi-cavity structure, uniform material distribution, high grinding efficiency.

-- U-shaped second grinding mechanism on the bottom of the grinding chamber, it can effectively eliminate the circulation phenomenon in the crushing process, and can improve the grinding capacity and crushing fineness.

-- Enlarged rotor spindle design, high-precision dynamic balance test, can ensure smoother operation and lower noise.

-- Optional temperature sensor, vibration meter, flame detector to achieve online monitoring.

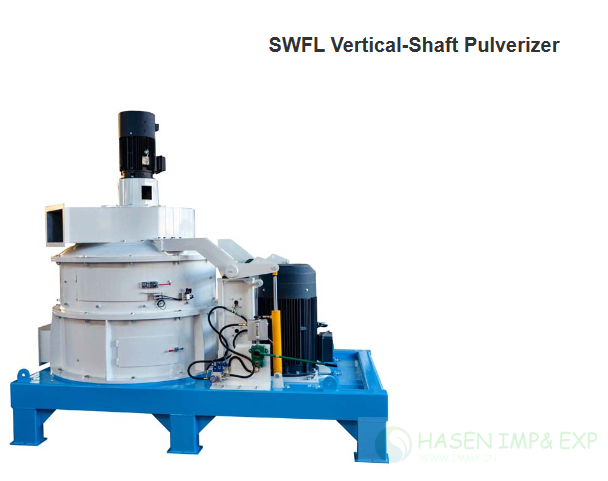

Device Description

-- As fine grinding mills in feed, flour, chemical, pharmaceutical, starch and other industries, fines size can be adjustable from 60 to 200 mesh.

-- Vertical shaft without screen style, compact structure, lower vibration and noise.

-- Unique crushing chamber structure and optimized grading system have the characteristics of high output and low energy consumption.

-- Device with hydraulic lift top cover for easy replacement of wearing parts.

Rye grain WUXI HASEN technologies serving the processing of high-protein cereals, including rye.

Rye is a fundamental cereal for various food and industrial productions, valued for its nutritional characteristics and versatility in the agri-food sector.

WUXI HASEN Industries offers state-of-the-art technology and cereal processing machinery for the complete treatment of rye, from cleaning and rye milling to final packaging. We guarantee quality and efficiency in every phase of the production process.

Our equipment is also perfectly suited for farms and livestock companies planning to produce animal feed directly for their own use. This machinery allows them to transform rye and other grains into high-quality flours and meals, perfect for animal feed processing.

To ensure complete and professional cleaning of the rye, WUXI HASEN Industries provides several advanced technological solutions.

These include grain decorticators and scourers, which are essential tools for removing impurities and dust. Furthermore, grain vibratory separators and industrial grain destoners are ideal for removing straw, stones, and other foreign bodies, thus guaranteeing a high-quality raw material.

Another important technology is represented by intensive sterilizers, which help to improve product safety by rebalancing the raw material. Finally, thanks to the use of grain moisture meter, it is possible to constantly monitor the ideal moisture level for the preservation and subsequent processing of the rye, guaranteeing excellent results at all production stages.

Our revolutionary DST – Dry Scrubbing Technology allows for waterless, dry cleaning of the cereal, reducing the risk of contamination and enhancing the sustainability of the process. For rye, cleaning must be particularly delicate to preserve the integrity of the kernel. In contrast, pulses, such as chickpeas or beans, may require a more vigorous treatment.

Rye milling is a delicate phase that can be executed using advanced machinery such as industrial roller mills, centrifugal impactors, semolina purifiers, plansifters, bran finishers, and general purpose grinding mills.

These milling machines make it possible to obtain flours and semolina of various granulations and qualities, meeting even the most specific production requirements. The use of disintegrators and filters ensures the purity and quality of the final product.

The Flexy Mill technology allows for an automatic and micrometric regulation of the gap between the rollers, making it possible to achieve the desired granularity without modifying the mill flow diagram. The WUXI HASEN offers a form of energy-efficient milling system, recovers kinetic energy generated during the grinding process and converts it into electricity, significantly improving energy efficiency and reducing consumption. WUXI HASEN torque motors, free of mechanical transmissions, ensure direct rotational movement, less friction, and a more compact plant layout.

To maintain the integrity of the processed rye, proper storage and packaging are essential. WUXI HASEN Industries offers solutions with augers, vertical bucket elevators, chain conveyors, scales, and innovative flour bagging systems that optimize the unloading and packaging process, ensuring speed, precision, and complete lot traceability.

WUXI HASEN Industries stands out for its consolidated experience and wide range of cereal processing machinery intended for the entire grain supply chain. Our technological solutions are designed to optimize productivity and quality, with a specific focus on sustainability and energy efficiency, also supporting the unique needs of livestock businesses in autonomous feed production.

A bioethanol hammer mill is used to reduce the size of biomass or grain (like corn, wheat, sorghum, cassava, or lignocellulosic materials) before fermentation. Proper size reduction improves starch or cellulose accessibility, which increases ethanol yield.

Here’s a clear, step-by-step explanation of how it works:

The hammer mill is part of feedstock preparation. Its job is to:

Grind raw material into fine particles

Increase surface area

Make downstream processes (liquefaction, saccharification, fermentation) more efficient

Feed hopper – raw material enters here

Rotating shaft (rotor) – driven by an electric motor

Hammers – steel blades mounted on the rotor

Screen (sieve) – controls final particle size

Discharge outlet – ground material exits

The hammer mill works on impact and shear forces.

Material feeding

Biomass or grain enters the mill through the hopper.

High-speed rotation

The motor rotates the rotor at high speed (typically 1,500–3,600 RPM).

Impact grinding

The swinging hammers hit the material repeatedly.

Material is broken by impact, shear, and attrition.

Size classification

Particles small enough pass through the screen openings.

Oversized particles remain inside until further crushed.

Discharge

The fine ground material exits and is sent to the next process (cooking or pretreatment).

Grain ethanol: 0.5–1.0 mm

Cellulosic biomass: 1–5 mm (depends on pretreatment method)

Screen size usually ranges from 0.5 to 6 mm

✔ Simple design

✔ Handles many feedstocks

✔ High throughput

✔ Low capital cost

✔ Easy maintenance

Moisture content (ideal: 10–15%)

Too wet → clogging

Too dry → excess dust

Hammer wear affects efficiency

Screen size controls energy consumption and yield

Feed rate must be consistent

Raw Material ↓ Hammer Mill (size reduction) ↓ Cooking / Pretreatment ↓ Liquefaction ↓ Saccharification ↓ Fermentation

For more information please visit youtube.com

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000