High Plansifter is one of the main grain oil equipment special in flour mill industry, utilized to classify intermediate products in accordance with their particle size at all milling stages and to separate out different flour types per quality required. www.immy.cn / www.immyhitech.com

High Plansifter

4, 6, 8-Compartment High Square Sifter

Appication:

FSFG plansifter is mainly applied in sifting and grading for system material during milling process in milling industry,and also used in other industries for granule materials.

Features:

1)Unique motor shaft sealing device ensures the flour not enter into the main equipment;

2)It is equipped with a resilient support of the balance iron under the main shaft;

3)Using SKF self-aligning roller bearings for drive shaft,to ensure highly concentric precise.

4)The top of sieve is adopted adjustment clamping mechanism;it has simple,convenient,and easy operation characteristics;

5)Using the new sieve box,the novel design patterns of sieve box increase the sieve area and capacity;

6)Sieve door and the channel sealing strict,to ensure no powder fleeing and powder leakage;

7)Plansifter framework uses automobile frames steel bending,welding,strong rigidity,and good fatigue resistance

8)The completely enclosed structure is adopted for the machine with the drive motor inside it,and has attractive appearance.

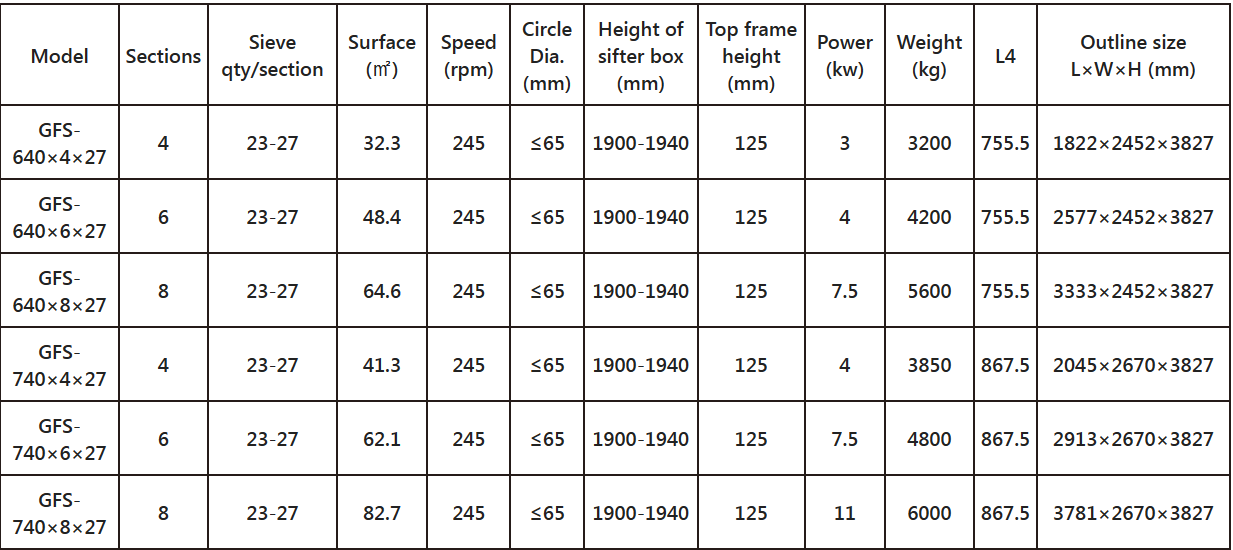

FSFG Main Technical Parameter:

FSFG640 main technical parameter

High Plansifter is one of the main grain oil equipment special in flour mill industry, utilized to classify intermediate products in accordance with their particle size at all milling stages and to separate out different flour types per quality required. www.immy.cn / www.immyhitech.com

Application field:

High Plansifter is one of the main equipment in Flour mill industry.

High Plansifter is utilized to classify intermediate products in accordance with their particle size at all milling stages and to

separate out different flour types per quality required.

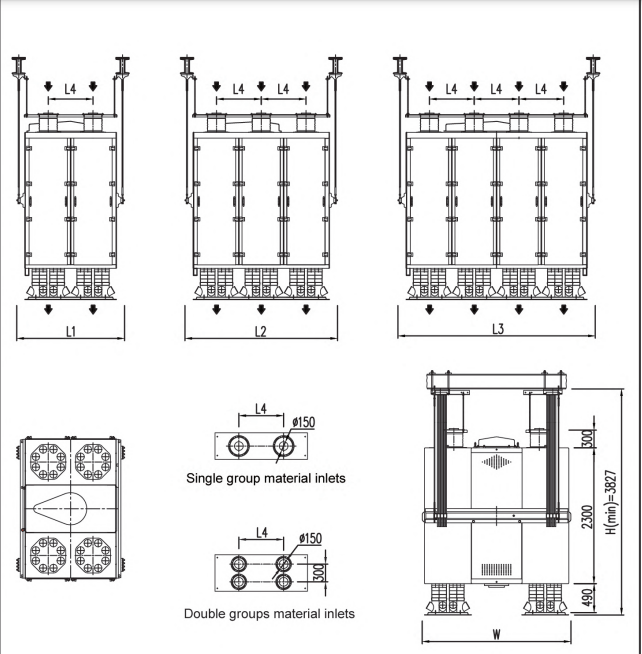

HIGH PLANSIFTER is divided into four cabinets and eight cabinets, and the sieve grid specifications are divided into 640mm and 740mm.

You can choose different models flexibly according to different technologies and production capacity.

Outer frames can be food grade polyurethane (PU) or wood with melamine;

The parts in contact with materials, lined with food-grade stainless steel, meet food safety and hygiene standards.

While inner frames are aluminum (ALUM) for long service life.

The machine can also be used for the grading of different grain types such as rye, corn(maize) etc.

Mainly used for wheat, corn and other grinding materials after screening and grading, can also be used as an

inspection sieve,is also suitable for screening and grading for materials in chemical, pharmaceutical, plastic and wine Industries.

Personalized selection:

HIGH PLANSIFTER is divided into four and eight silos, sieve size is 640mm and 740mm

You can choose different models flexibly according to different process and capacity.

Fiberglass hanging canes;

Products inlet and outlet sleeves;

Inlet and outlet boards with stronger suspensions;

Inox steel or plastic material joints according to the flow sheet;

Sieve cleaning pads products expellers

![]()

https://youtu.be/edphRLLWUN0

FAQ: Whats the Buckwheat processing? How dose it working?

Industrial buckwheat processing: plant design and milling technology

Buckwheat is a naturally gluten-free pseudo-cereal that requires specific processes to yield high-quality flour. Unlike hard wheat, its unique botanical and physical structure mandates a customized approach to milling plant design and processing.

High-performance buckwheat processing equipment

The production of premium flour starts with the right technology. To handle the fragility and irregularity of this pseudo-cereal, specialized buckwheat processing equipment is essential. From the initial intake to the final bag, every machine must be calibrated to prevent damage to the kernel while ensuring maximum yield and purity.

Buckwheat grain cleaning: Our plant and machinery

The first step in the process is cleaning, which is essential to obtaining a raw material free from impurities such as stones, dust, and foreign seeds. For buckwheat, this stage is particularly delicate because the kernels are smaller and more irregular than those of wheat.

Our Industries machinery allows for deep and accurate cleaning thanks to the use of air screen grain cleaner, brush machines, and latest-generation destoners, capable of effectively separating foreign bodies. During this phase, tools like a precision grain moisture meter help maintain consistent processing parameters, ensuring the quality of the incoming product.

Compared to hard wheat, buckwheat grain cleaning requires greater set-up flexibility due to the grain’s different size and density. Our modular approach guarantees maximum precision in raw material preparation.

Buckwheat Milling: Flexy Mill Technology

Milling buckwheat is the core of the processing operation and represents one of the most critical stages.

The Flexy Mill system allows for automatic, micrometric regulation of the milling process, enabling changes in the speed and direction of the rolls without modifying the roller mill diagram. Our Direct Drive System (ODS), the distance between the rolls can be adjusted with a precision of up to 0,004 mm, offering total control over granularity and yield.

The digital interface allows for the storage of various processing “recipes,” adapting the process to the specific characteristics of buckwheat, which is more fragile and irregular than hard wheat.

At the heart of this phase is the roller mill, an innovative machine that combines high energy efficiency with maximum operational flexibility. Thanks to its direct drive and independent roll control, it can process buckwheat with extreme delicacy, preserving its nutritional and aromatic properties. The precision adjustment ensures uniform flour, minimizing waste and mechanical wear.

Supporting the initial breaking and kernel preparation is impact detacher, ideal for opening the product and improving the efficiency of the subsequent roller mill. This machinery uses centrifugal force to controllably separate the kernel parts, ensuring more homogeneous milling and a higher yield in the reduction phase.

For finer grinding or specific productions, We also uses the hammer mill, designed to treat buckwheat with great precision, preventing overheating and keeping the product characteristics intact.

Discharge and storage of milled buckwheat

After milling, the product is safely and hygienically discharged and stored. Our Industries buckwheat mill plants are designed to manage continuous and efficient flows, utilizing precision scales, screw conveyors, vertical bucket elevators, and vibrating silo extractors that ensure correct product flow and preserve quality.

In the case of buckwheat, the flour must be protected from humidity and potential contamination. Our systems guarantee cleanliness and security, ensuring the flour does not come into contact with cereals containing gluten.

Buckwheat flour packaging

Packaging is the final stage of processing. We propose integrated lines that allow buckwheat flour packaging in sacks, big bags, or custom containers, maintaining maximum hygiene and traceability.

The bagging stations ensure precise dosing and an automated flow that reduces product manipulation and changeover times. The system is designed to handle packaging destined for the “gluten-free market,” with solutions that guarantee food safety and sanitation.

FAQ 2:

Whats the high plansifter used for?

Plansifter is a unique machine for sifting flours, combining technological innovation with durability, fully complying with health standards. Its structure stands out for the use of noble materials, such as stainless steel and anodized aluminum, preventing flour contamination and reducing internal condensation.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000