Intensive Dampener For evenly moisture grain during wheat maize millet flour, oil processing line. www.immyhitech.com

Intensive Dampener For evenly moisture grain during wheat maize millet flour, oil processing line. www.immy.cn / www.immyhitech.com

Application field:

INTENSIVE DAMPENER machine is used to evenly water grain during processing.

The rotating blade can ensure that the water can effectively penetrate into the grain and distribute evenly. The power requirement is low,

and the damage and breakage rate of the material in the process of watering is very low.

Features:

With all stainless steel materials to avoid water corrosion of the body.

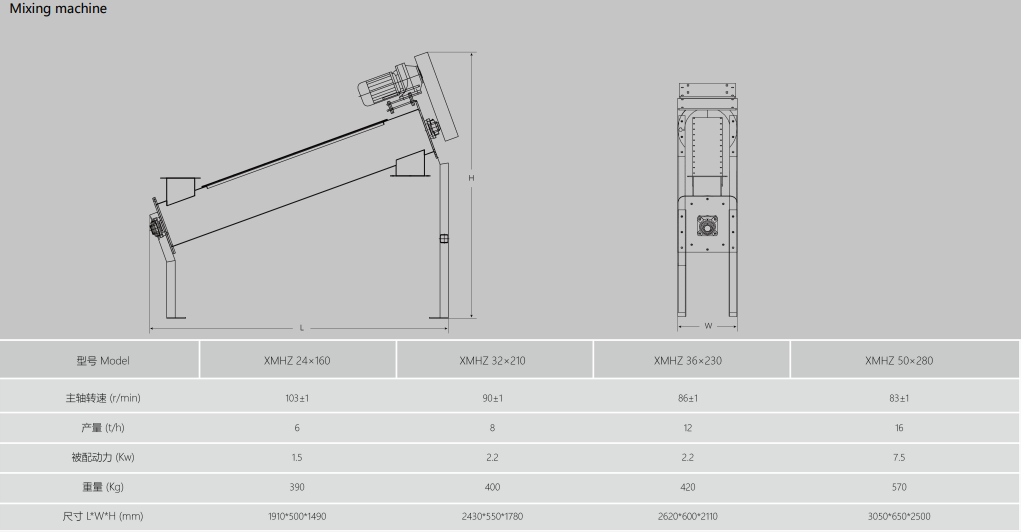

Simple and flexible installation, multiple models using different sizes of factories.

Can be linked to multiple versions of water control system.

Application:

INTENSIVE DAMPENER machine applied maximum in 1500t/ 24H.

Capacity of intensive dampener maximum capacity 3000t/24h wheat maize flour making workshop stable and reliable operation.

We are leading Integrated flour mill engineering equipment manufacture in China, Inquiry us if you need high standard Full Auto Flour Mill Line from 100-5000 tons per a day.

Hope to be your valued supplier of grain and oil engineering equipment EPC turnkey project from 100TPD to 3000 TPD in China.

FACTORY VIEW, PRODUCT SITE SEEING:

CONTROLLER& INTENSIVE DAMPENER

For more information please visit:

https://www.linkedin.com/company/28728730/admin/feed/posts

https://www.facebook.com/maizemachinehasen

https://www.blogger.com/u/0/blog/post/edit/4145872885004376169/7743054326348463733

The WUXI HASEN Intensive Dampener is a specialized machine used in grain milling systems to condition raw grains such as wheat, maize, and millet by adding moisture evenly before they enter the milling process. Proper moisture conditioning helps soften the grain kernels so that they mill more efficiently, producing flour with better granularity and yield. Uniform moisture distribution also helps protect milling equipment and improves overall grinding performance. The WUXI HASEN Intensive Dampener ensures grains are conditioned consistently, which is key to high-quality milling. For more details or to inquire about the WUXI HASEN Intensive Dampener, please contact WUXI HASEN For Intensive Dampener.

The WUXI HASEN Intensive Dampener operates by allowing grain to enter through an inlet where water is added and mixed intensively using specially designed rotating blades or paddles. These rotors create a vigorous mixing action that ensures water adheres to and penetrates throughout the grain kernels quickly and uniformly. The turbulent motion avoids kernel damage and allows moisture to saturate each grain effectively. This conditioning step prepares the grain to mill more easily and precisely, reducing the overall milling time and energy needed. For inquiries about how the WUXI HASEN Intensive Dampener functions in your system, please contact WUXI HASEN For Intensive Dampener.

Using a WUXI HASEN Intensive Dampener yields several advantages for flour mill customers. First, the machine ensures a homogenous moisture level throughout all grain kernels, which leads to better grinding performance and improved flour quality. Second, conditioning with an intensive dampener reduces waste and breakage since the process softens kernels without harming their structure. Third, it supports higher throughput and consistent milling results, which enhances overall productivity and profitability for large milling operations. These benefits make the WUXI HASEN Intensive Dampener a strategic component in any modern grain milling system. For more information about benefits, please contact WUXI HASEN For Intensive Dampener.

The WUXI HASEN Intensive Dampener is suitable for a wide range of cereals and grains, including wheat, maize, and millet. Whether used in wheat flour mills, maize flour processing lines, or other cereal handling systems, the intensive dampener is designed to handle varying grain sizes and characteristics. This flexibility ensures efficient moisture conditioning even when dealing with diverse grain properties or batch compositions. The machine’s ability to adapt to different grains makes the WUXI HASEN Intensive Dampener a versatile choice for multi-purpose milling applications. For further grain compatibility questions, please contact WUXI HASEN For Intensive Dampener.

In wheat milling, the WUXI HASEN Intensive Dampener serves a crucial conditioning role by increasing the moisture content of cleaned wheat to a precise level. Proper moisture levels are vital for reducing bran toughness and minimizing the adhesion between the endosperm and bran layers, which in turn enhances grinding efficiency and flour quality. The conditioning process also ensures that wheat kernels are prepared uniformly so that the milling equipment operates at optimal performance levels with reduced wear and tear. For detailed functional specifications of the WUXI HASEN Intensive Dampener, please contact WUXI HASEN For Intensive Dampener.

The moisture control in the WUXI HASEN Intensive Dampener typically uses precision water injection systems integrated with the grain inlet. As grains flow into the dampener, water is added at controlled rates to achieve the target moisture content. The advanced rotor mixing action ensures that each kernel absorbs water uniformly, greatly improving consistency compared with older, slower conditioning systems. These precisely controlled moisture levels are critical for achieving the desired grain pliability and milling outcomes. To explore specific moisture control options with the WUXI HASEN Intensive Dampener, please contact WUXI HASEN For Intensive Dampener.

Yes, the WUXI HASEN Intensive Dampener can significantly improve milling yields. By ensuring that moisture is evenly distributed across all grains, the kernel structure becomes conditioned in a way that enables smoother cutting and separation of bran from endosperm during milling. As a result, flour extraction rates increase, and the amount of fine flour produced is higher. Optimized moisture levels also reduce energy consumption in downstream milling equipment and contribute to a consistent final product. To discuss how the WUXI HASEN Intensive Dampener can optimize your yield, please contact WUXI HASEN For Intensive Dampener.

The WUXI HASEN Intensive Dampener dramatically reduces conditioning time compared to traditional static dampening systems. Its high-speed rotor and continuous mixing action achieve rapid and uniform moisture absorption in a fraction of the time normally required. Some intensive dampeners can cut conditioning times from hours to minutes, boosting mill throughput and responsiveness to shifting production demands. This speed and efficiency make the WUXI HASEN Intensive Dampener especially valuable in high-volume milling operations. For details on conditioning times with the WUXI HASEN Intensive Dampener, please contact WUXI HASEN For Intensive Dampener.

The WUXI HASEN Intensive Dampener is engineered for reliable, continuous operation. Its stainless steel construction resists corrosion and simplifies cleaning, while the rotating components are designed for durability and low maintenance needs. Operators should perform routine checks on water injection systems and rotor assemblies to ensure that moisture addition remains precise and that moving parts are operating smoothly. Periodic servicing and access to spare parts further ensure long service life and minimal downtime. For advice on maintenance of the WUXI HASEN Intensive Dampener, please contact WUXI HASEN For Intensive Dampener.

The WUXI HASEN Intensive Dampener can be configured to integrate seamlessly into standard milling lines. With flexible installation options and compatibility with automated water control systems, it can be tailored to fit existing conveyors, grain handling modules, and moisture monitoring equipment. Technical support can assist with layout optimization and ensure that the dampener works harmoniously with current milling processes to maximize performance. For personalized integration support for the WUXI HASEN Intensive Dampener, please contact WUXI HASEN For Intensive Dampener.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000