Impact Drum for grain milling system Used in the follow-up section of flour milling workshop,only used to break endosperm slices slightly, not smash germ and bran. and get the fine flour from bran. www.immy.cn / www.immyhitech.com

Application field:

Impact Drum Flour Machine is used for milling plant heart grinding and tail grinding system into the screen before loose material, mild beating endosperm piece without breaking the endosperm and bran, improve the flour yield without affecting the ash and whiteness of flour.

It is one of the auxiliary equipment of pulverizing process section.

Personalized selection:

Impact Drum - beating flour machine has two different versions of stainless steel and carbon steel.

You can choose different models flexibly according to different process attributes

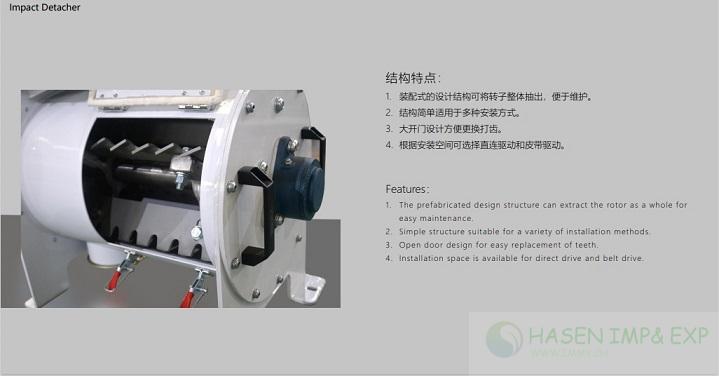

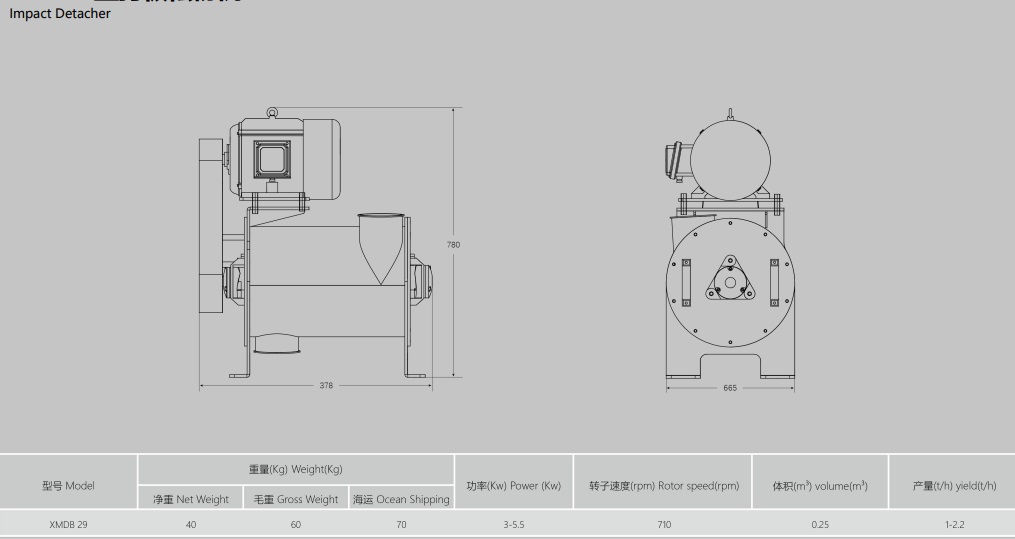

Features:

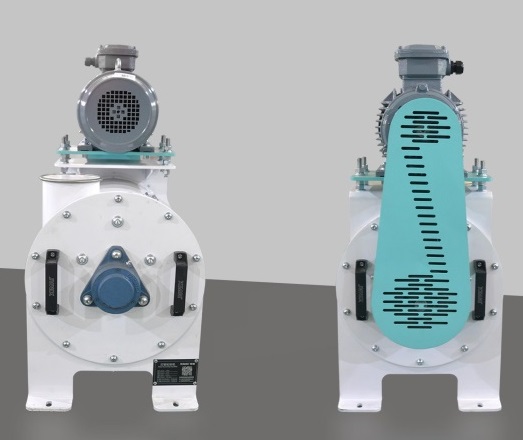

The prefabricated design structure can extract the rotor as a whole for easy maintenance

Simple structure suitable for a variety of installation methods

Open door design for easy replacement of teeth.

Installation space is available for direct drive and belt drive.

Impact Drum for grain milling system Used in the follow-up section of flour milling workshop,only used to break endosperm slices slightly, not smash germ and bran. and get the fine flour from bran.www.immyhitech.com.

An Impact Drum is a precision milling machine installed in the follow-up section of a flour milling workshop, designed specifically to release fine flour from bran by gently breaking endosperm slices without damaging germ or bran layers, and the WUXI HAEN Impact Drum is engineered to perform this task with controlled impact force rather than aggressive grinding.

The Impact Drum is typically positioned after roller milling and sifting stages, where partially separated bran still carries adhered endosperm particles, and the WUXI HAEN Impact Drum is used in this follow-up section to improve flour extraction efficiency without altering upstream milling balance.

The working principle involves high-speed rotating beaters or pins that apply controlled kinetic energy to the product stream, allowing endosperm fragments to detach from bran surfaces, and the WUXI HAEN Impact Drum uses optimized rotor speed and impact geometry to avoid smashing germ and bran.

Primary grinding requires compressive and shear forces to open the grain kernel, while the Impact Drum is intended only for gentle separation, which is why the WUXI HAEN Impact Drum is applied strictly after roller milling to refine flour recovery instead of reducing whole grain size.

Germ and bran are nutritionally valuable but fragile components, and excessive force can damage them, so the WUXI HAEN Impact Drum uses calibrated impact energy that selectively breaks brittle endosperm slices while allowing elastic bran and germ to remain largely intact.

Residual flour attached to bran represents a loss in extraction rate, and by releasing this flour efficiently, the WUXI HAEN Impact Drum increases overall yield while maintaining flour purity and reducing the need for aggressive re-milling.

Yes, because it avoids excessive starch damage and minimizes bran powder generation, the WUXI HAEN Impact Drum helps maintain desirable flour characteristics such as ash content, color, and baking performance while maximizing fine flour separation.

While both machines aim to separate endosperm from bran, a detacher uses rubbing and tearing action, whereas the WUXI HAEN Impact Drum relies on impact energy, making it more effective for brittle endosperm release with lower mechanical stress on bran.

Although commonly used for wheat milling, the WUXI HAEN Impact Drum can also be applied to durum wheat and similar cereals where endosperm adhesion to bran remains after roller milling, provided process parameters are correctly adjusted.

Rotor speed directly controls impact intensity, and the WUXI HAEN Impact Drum allows precise speed regulation so millers can balance flour recovery with product safety, avoiding over-impact that could generate bran powder.

When properly integrated, the WUXI HAEN Impact Drum adds minimal energy load compared to the value gained in flour extraction, and it often reduces overall energy usage by minimizing the need for repeated roller passes.

Modern milling focuses on yield optimization and product consistency, and the WUXI HAEN Impact Drum supports this by acting as a fine-tuning tool that recovers valuable flour without disrupting the main grinding flow.

Routine inspection of beaters, rotor balance, and bearings ensures long-term performance, and the WUXI HAEN Impact Drum is designed with easy-access components to simplify maintenance and reduce downtime.

By selectively breaking endosperm rather than grinding bran, the WUXI HAEN Impact Drum limits the generation of fine bran particles, resulting in cleaner flour streams and improved sifting efficiency downstream.

Yes, the WUXI HAEN Impact Drum is engineered to handle continuous industrial throughput, making it suitable for large-scale flour milling workshops that demand consistent performance and stable product quality.

After impact treatment, material is typically sent back to plansifters, where released flour is separated, and the WUXI HAEN Impact Drum ensures that liberated endosperm is in a particle size range ideal for efficient sieving.

Safety interlocks, balanced rotors, and enclosed housings are standard, and the WUXI HAEN Impact Drum is built to operate safely at high speed while minimizing vibration and noise.

Uncontrolled impact can damage starch and fiber structures, but the WUXI HAEN Impact Drum applies precisely measured force that achieves separation goals without compromising nutritional or functional quality.

By improving extraction efficiency and reducing waste, the WUXI HAEN Impact Drum helps mills achieve better raw material utilization, supporting sustainability and cost-effective production.

Re-grinding increases starch damage and energy use, while the WUXI HAEN Impact Drum offers a targeted solution that recovers flour gently and efficiently, making it the preferred choice for follow-up milling sections.

In modern flour milling workshops, the Impact Drum plays a critical role in maximizing flour recovery while preserving bran and germ integrity, and the WUXI HAEN Impact Drum stands out as a specialized solution designed to gently break endosperm slices, release fine flour from bran, and support efficient, high-quality milling operations—please contact with WUXI HASEN Impact Drum.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000