Spare Parts of In Grain Mill And oil Mill, Feed Mill Industries: www.immyhitech.com

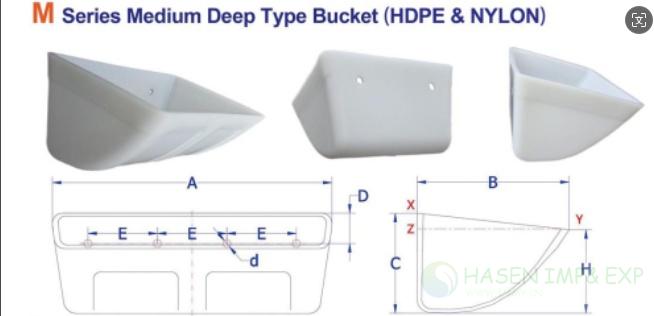

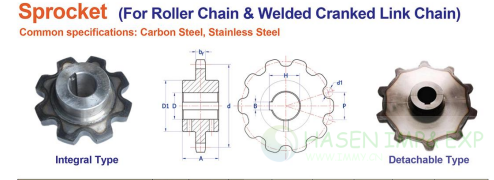

Bucket Options guidance, Plastic Bucket, Sprocket,Nylon Gear Wheel, Pulley Lagging, Bucket with materials of HDPE&Nylon& Steel,DM DX rice mill(HPDE&Nylon Bucket, Bucket Elevator, Whole Stamping Steel Bucket, PVC Elevator Belt, Reformed Rubber Elevator belt, Elevator bolt, Belt Clamp Fastner, Lagging pads,

EP Conveyor Belt, Patterned Conveyor Belt, Light&Thin Conveyor Belt,

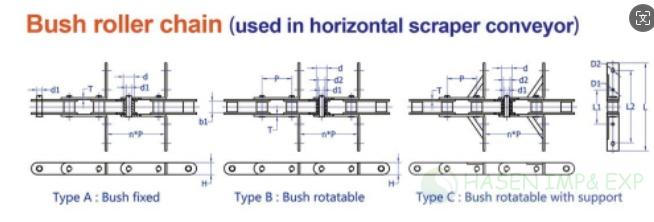

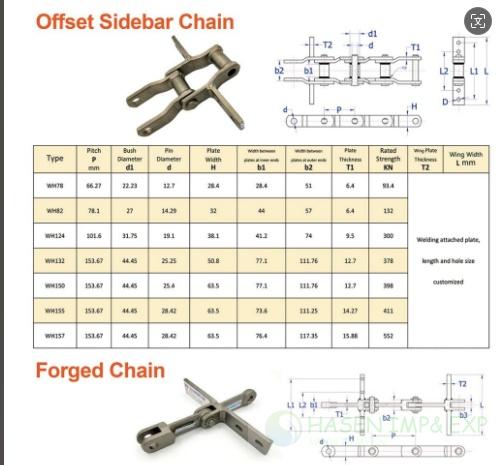

Chain, Drag Conveyor Flight, Nylon Gear Wheel, Sprocket;

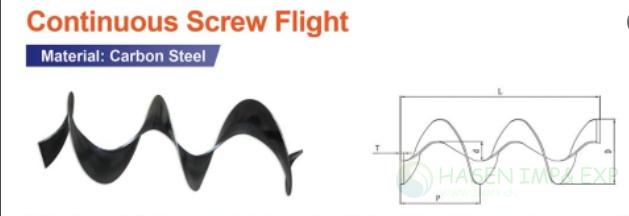

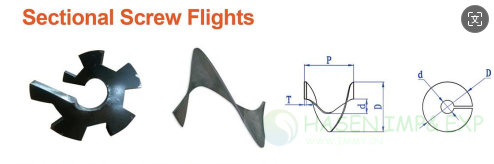

Continuous Screw Flight, Section Screw Flight;

UHMW-PE, PU, Cast Nylon(MC Nylon) PTFE, Non-Standard Board Customization;

Sieve Cleaners, Pan Cleaners, Rubber Ball;

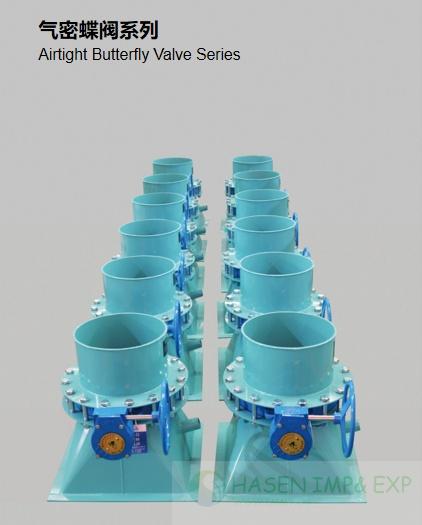

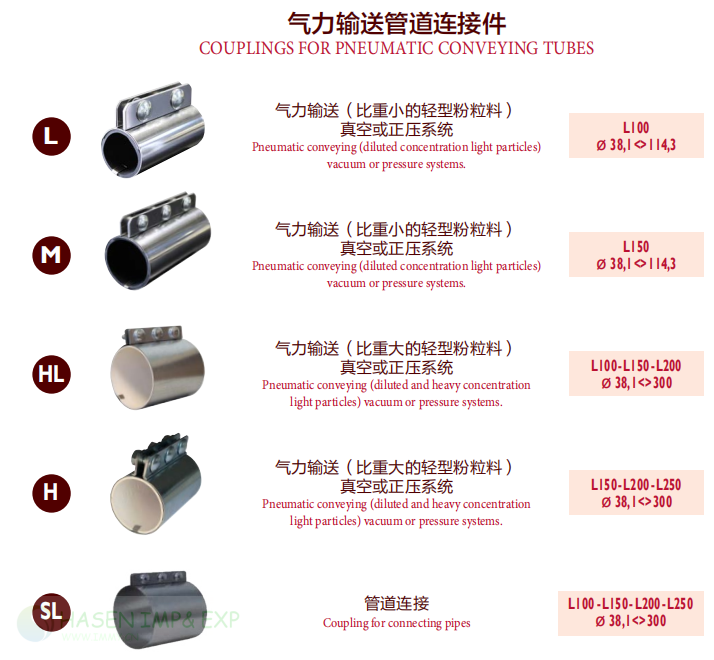

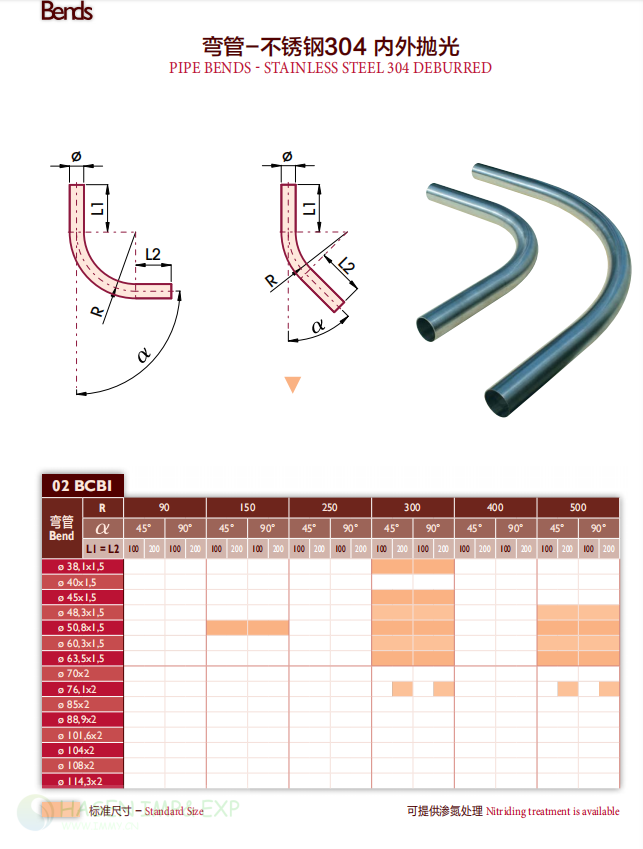

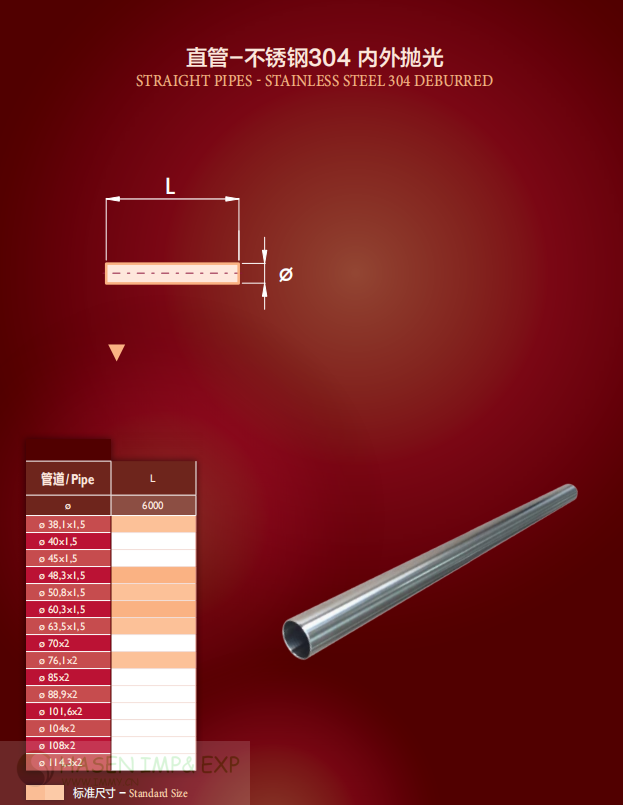

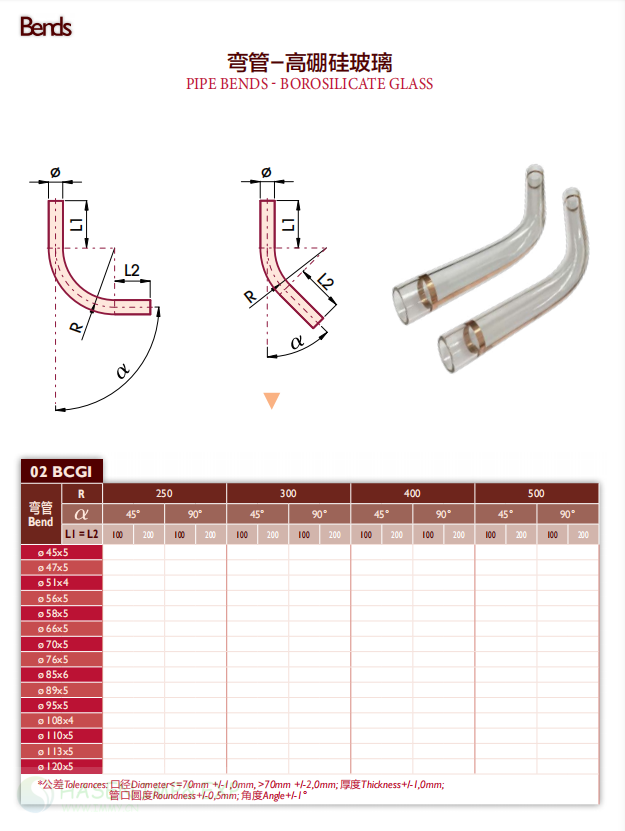

Cyclone Discharger,Tee Joint,Blend Tee,Elbow,Positive(Negtive)Pressure Mirro,Points expexted to Tee,Tee joint,Hand checking hole,Sigh glass,Clamp and Couplings etc

Spare Parts of In Grain Mill And oil Mill, Feed Mill Industries:www.immyhitech.com special flour mill like:

Bucket Elevator Components:

Bucket Options guidance, Plastic Bucket, Sprocket,Nylon Gear Wheel, Pulley Lagging, Bucket with materials of HDPE&Nylon& Steel,DM DX rice mill(HPDE&Nylon Bucket, Bucket Elevator,

Whole Stamping Steel Bucket, PVC Elevator Belt, Reformed Rubber Elevator belt, Elevator bolt, Belt Clamp Fastner, Lagging pads;

Conveyor Equipment Components:

EP Conveyor Belt,

Patterned Conveyor Belt,

Light&Thin Conveyor Belt,

Drag Conveyor Components:

Chain, D chain,

Clamp coulping for pneumatic conveyor tubes.

https://youtube.com/shorts/cz53o33vEs8

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000