Air Aspiration Channel Separator, it separate light impurities in the grain from granular material, and adopts form of closed circuit circulating air. Its categories into 3 types: multi channel suction duct.www.immyhitech.com

Air Aspiration Channel Duct Separator. Separate light impurities in the grain from granular material, and adopts form of closed circuit circulating air. Its catagories into 3 types: multi channel suction duct. www.immy.cn / www.immyhitech.com

MULTI CHANNEL VERTICAL SUCTION DUCT

For the cleaning of raw grain materials, impurities such as straw, wheat awns, soil, stone and worm wheat should be removed respectively.

At this time, the equipment in the process should have screening equipment (rotary vibrating screen or vibrating screen), and also have stone removal equipment (a variety of stone removal machine options) and wind selection equipment to remove wheat, soil and other light impurities (circulating air selector with its own air path does not need external air network) or vertical suction duct (this wind selection equipment to remove light impurities need to be realized with the help of shacron, fan, air pipe.

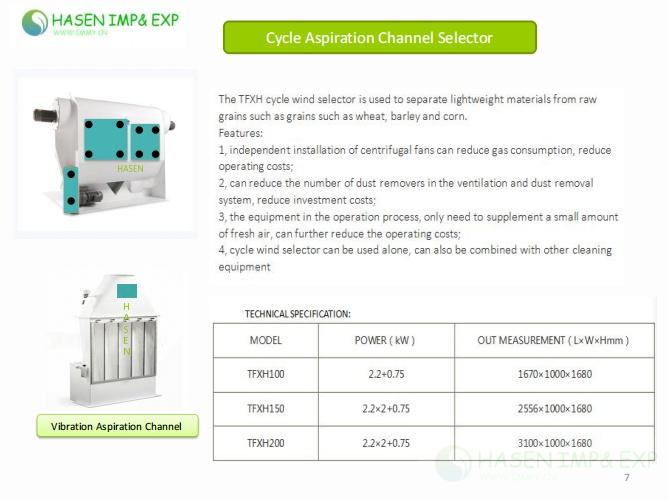

TFXH CIRCULATING SUCTION DUCT SEPARATOR

(TFXH SERIES CIRCULATING WINNOWING EQUIPMENT)

TFXH series circulating air separator is specially used to suck air from grains (such as: wheat, corn, barley, etc.) to separate low specific gravity impurities such as husk and dust.

It can be used in grain depots, flour mills, rice mills, corn processing plants, oil mills, feed mills, starch mills, alcohol mills, etc. It can be used alone or in combination with a vibrating screen, a flat rotary screen or a threshing machine.

The equipment can separate the light impurities in the grain from the granular material, and adopts the form of closed circuit circulating air, which itself has the function of life removal, that is, saving other biological removal equipment, and does not exchange gas with the outside world.

TFXH Recycle Suction Separator is to absorb air from grain in separation of husk and other low specific gravity impurities in wheat and maize flour milling processing line.

Application field:

TFXH CIRCULATING AIR SUCTION SEPARATOR is dedicated to absorb air from grain (such as: wheat corn, barley, oil, etc.) in the separation of husk dust and other low specific gravity impurities, it can be used for grain depot, flour factory, rice factory, corn processing plant, oil factory, feed factory, wine factory, etc. Its biggest characteristic: suction area is large, save wind, air selection effect is good.

SPECIFICATION OF TFXH CIRCULATING AIR SUCTION SEPARATOR

.png)

AIR-INTAKE DUC TFDZ

For the cleaning of raw grain materials, impurities such as straw, wheat awns, soil, stone and worm wheat should be removed respectively. At this time, the equipment in the process should have screening equipment (rotary vibrating screen or vibrating screen), and also have stone removal equipment (a variety of stone removal machine options) and wind selection equipment to remove wheat, soil and other light impurities (circulating air selector (with its own air path does not need external air network) or vertical suction duct (this wind selection equipment to remove light impurities need to be realized with the help of shacron, fan, air pipe.

For more information please visit:

https://wordpress.com/post/wheatflourmill0.wordpress.com/623

https://www.blogger.com/blog/posts/4145872885004376169

https://www.linkedin.com/company/28728730/admin/feed/posts/

https://www.tumblr.com/blog/flourmillmachine

https://www.instagram.com/flourmachine/

An Air Aspiration Channel Separator is an essential cleaning machine used in a flour mill processing line to remove light impurities from grain before milling. The Air Aspiration Channel Separator works by using a controlled airflow to separate husk, dust, straw, and other lightweight contaminants from heavier granular material such as wheat, maize, or rice, improving overall milling quality and equipment safety.

The working principle of an Air Aspiration Channel Separator is based on aerodynamic separation, where grain falls through a vertical or inclined air channel. In an Air Aspiration Channel Separator, light impurities are lifted by circulating air while clean grain flows downward due to gravity, ensuring efficient separation without damaging kernels and maintaining a stable processing flow.

An Air Aspiration Channel Separator plays a critical role in protecting downstream machines such as rollers and sifters. By installing an Air Aspiration Channel Separator at the grain intake or cleaning section, flour mills can reduce wear, improve flour purity, and enhance food safety by removing unwanted lightweight contaminants early in the process.

An Air Aspiration Channel Separator is designed to remove light impurities including dust, chaff, husks, empty grains, and straw fragments. Through precise airflow control, the Air Aspiration Channel Separator ensures that only low-density materials are extracted, while valuable granular material remains unaffected and continues through the milling line.

A closed circuit circulating air system means the Air Aspiration Channel Separator reuses air within a sealed loop instead of exhausting it outside. This design allows the Air Aspiration Channel Separator to reduce energy consumption, minimize dust emission, and maintain consistent separation efficiency regardless of environmental conditions in the flour mill.

The Air Aspiration Channel Separator is generally categorized into three types based on airflow and channel configuration. One widely used form of Air Aspiration Channel Separator is the multi channel suction duct type, which provides higher capacity and better separation accuracy for modern high-output flour mill processing lines.

A multi channel suction duct Air Aspiration Channel Separator features several parallel air channels to increase separation area and efficiency. By using a multi channel suction duct, the Air Aspiration Channel Separator can handle larger grain volumes while maintaining uniform airflow distribution, making it ideal for industrial-scale flour mills.

By pre-cleaning grain effectively, an Air Aspiration Channel Separator ensures smoother operation of downstream equipment. The Air Aspiration Channel Separator reduces blockages, lowers machine wear, and stabilizes milling performance, resulting in higher flour yield, better product consistency, and reduced maintenance costs.

Yes, an Air Aspiration Channel Separator can be adjusted by regulating airflow velocity and feed rate. This flexibility allows the Air Aspiration Channel Separator to process different grains such as wheat, corn, barley, and rice efficiently, ensuring optimal impurity removal regardless of grain size or density.

When choosing an Air Aspiration Channel Separator, factors such as processing capacity, type of grain, impurity level, and energy efficiency should be considered. A well-designed Air Aspiration Channel Separator with a closed circuit circulating air system and multi channel suction duct configuration ensures long-term reliability and superior cleaning performance.

Regular inspection and cleaning are necessary to keep an Air Aspiration Channel Separator operating efficiently. Proper maintenance of the Air Aspiration Channel Separator, including checking air ducts, seals, and adjustment mechanisms, helps maintain stable airflow and prolongs machine lifespan in continuous flour mill operation.

Choosing an experienced manufacturer ensures quality and performance of the Air Aspiration Channel Separator. A trusted supplier of Air Aspiration Channel Separator equipment will provide technical support, customization options, and proven solutions tailored to modern flour mill processing requirements.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000