Gravity Grading Destoner for grain,feed,oil processing machine line.Grading Stone Removal is e core host of food processing equipment, used in a variety of grain grains such as wheat, barley, corn, rye, oats and rice:www.immyhitech.com

Application field:

Gravity Grading Destoner for grain,feed,oil processing machine line.Grading Stone Removal is e core host of food processing equipment, used in a variety of grain grains such as wheat, barley, corn, rye, oats and rice:www.immyhitech.com It is the food processing process to ensure food safety, food hygiene of the core section of equipment.

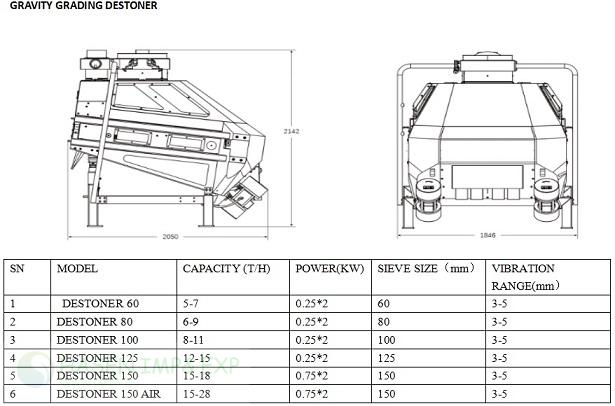

Stone removal machine has a variety of models;

Multiple models from 5 tons per hour to 28 tons per hour.

You can choose different models flexibly according to different process and capacity

Ash mortise and tenon structure with aluminum sieve;

Sheet metal construction for high precision manufacturing;

Lighting system;

The matching fan will constitute a complete set of stone remove machine system.

![]()

For more information please visit:

https://wordpress.com/post/wheatflourmill0.wordpress.com/612

https://www.blogger.com/blog/post/edit/4145872885004376169/1335407323274249708

https://www.facebook.com/maizemachinehasen/

https://www.linkedin.com/company/28728730/admin/feed/posts/

A Gravity Grading Destoner(Stone Removal) is a critical cleaning machine used in grain, feed, and oil processing lines to efficiently separate stones, gravel, glass, and other heavy impurities from raw materials. By using the principle of density difference and airflow, Gravity Grading Destoner(Stone Removal) ensures that grains such as wheat, barley, corn, rice, oats, and rye are cleaned before further processing. This improves product safety, protects downstream equipment, and enhances overall processing efficiency, making Gravity Grading Destoner(Stone Removal) an essential host machine in modern food processing plants.

The working principle of Gravity Grading Destoner(Stone Removal) is based on gravity, vibration, and controlled airflow. As material enters the deck, air passes upward, stratifying the mixture so heavier stones sink while lighter grains float. The vibrating motion then moves the heavier impurities in the opposite direction for discharge. Gravity Grading Destoner(Stone Removal) operates continuously and precisely, allowing processors to remove stones without damaging grains. This stable and reliable process makes Gravity Grading Destoner(Stone Removal) widely used in large-scale grain and feed production lines.

Gravity Grading Destoner(Stone Removal) is suitable for a wide range of agricultural products, including wheat, barley, corn, rice, rye, oats, sorghum, and various oilseeds. Due to its adjustable airflow and vibration parameters, Gravity Grading Destoner(Stone Removal) can handle grains of different sizes, shapes, and moisture levels. This flexibility allows food processors to use one Gravity Grading Destoner(Stone Removal) across multiple processing lines, improving equipment utilization and reducing operational costs.

Food safety is a top priority in grain and feed processing, and Gravity Grading Destoner(Stone Removal) plays a vital role in meeting safety standards. Stones and heavy impurities can damage milling equipment and contaminate final products if not removed. Gravity Grading Destoner(Stone Removal) ensures clean raw materials, reducing the risk of foreign matter in flour, feed, and oil products. By integrating Gravity Grading Destoner(Stone Removal) into the production line, manufacturers can comply with international food safety regulations and improve consumer trust.

The main advantages of Gravity Grading Destoner(Stone Removal) include high stone removal efficiency, low grain loss, stable operation, and easy maintenance. Compared with traditional cleaning equipment, Gravity Grading Destoner(Stone Removal) offers more precise separation and higher capacity. Its robust design supports continuous operation in industrial environments, while adjustable settings allow operators to optimize performance for different materials. These advantages make Gravity Grading Destoner(Stone Removal) a preferred solution for modern grain and feed processing plants.

Gravity Grading Destoner(Stone Removal) is typically installed after pre-cleaning equipment and before milling or further processing. It works seamlessly with vibrating screens, aspirators, and magnetic separators. Gravity Grading Destoner(Stone Removal) enhances overall line efficiency by removing heavy impurities early, reducing wear on downstream machines. Proper integration of Gravity Grading Destoner(Stone Removal) ensures smooth material flow and consistent product quality throughout the processing line.

Several factors influence the performance of Gravity Grading Destoner(Stone Removal), including airflow volume, vibration frequency, deck inclination, and material moisture content. Correct adjustment of these parameters allows Gravity Grading Destoner(Stone Removal) to achieve optimal separation efficiency. Regular inspection and maintenance also play a key role in sustaining long-term performance. When properly operated, Gravity Grading Destoner(Stone Removal) delivers reliable and consistent stone removal results.

Routine maintenance of Gravity Grading Destoner(Stone Removal) includes cleaning the deck, checking airflow systems, inspecting vibration motors, and tightening fasteners. Preventive maintenance helps avoid downtime and extends equipment lifespan. Gravity Grading Destoner(Stone Removal) is designed for easy access to key components, allowing operators to perform inspections efficiently. With proper care, Gravity Grading Destoner(Stone Removal) can operate reliably for many years in demanding production environments.

Selecting a professional manufacturer ensures that Gravity Grading Destoner(Stone Removal) meets industrial standards and delivers stable performance. Experienced manufacturers provide customized solutions, technical support, and reliable after-sales service. High-quality materials and precise engineering enhance the durability of Gravity Grading Destoner(Stone Removal). Partnering with a trusted supplier helps processors achieve higher efficiency, better product quality, and long-term operational success.

For high-performance Gravity Grading Destoner(Stone Removal) used in grain, feed, and oil processing machine lines, choosing a proven supplier is essential. Professional solutions ensure efficient stone removal, food safety compliance, and stable operation across various grains. To learn more about advanced designs, technical specifications, and customized configurations of Gravity Grading Destoner(Stone Removal), please contact with WUXI HASEN (www.immyhitech.com) ForGravity Grading Destoner(Stone Removal).

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000