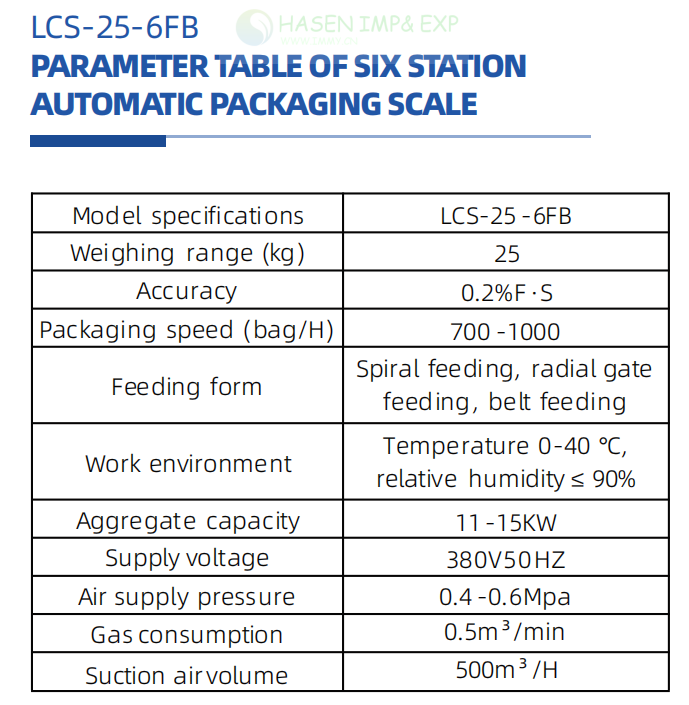

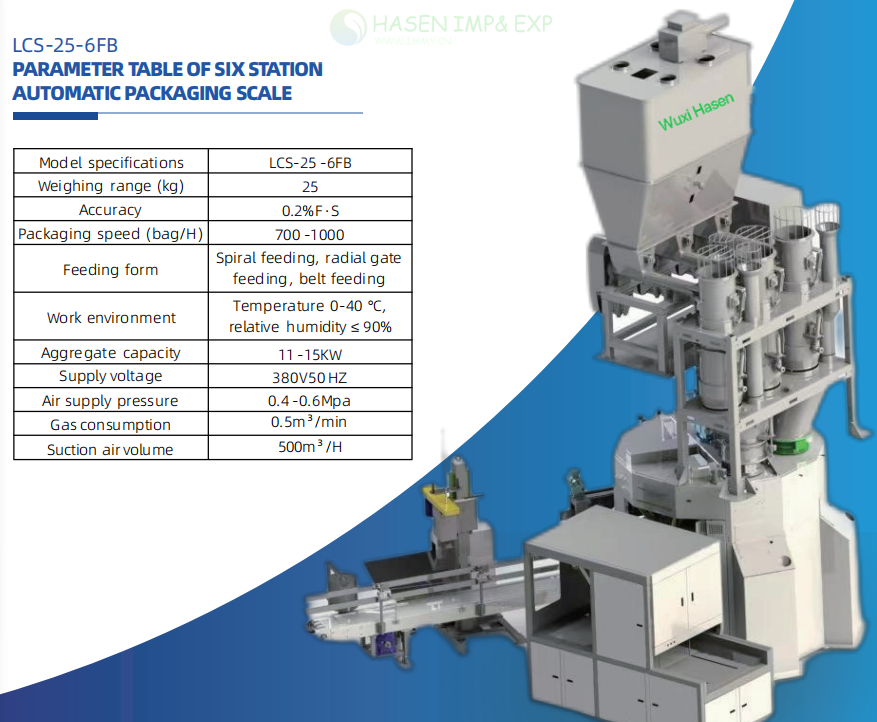

Flour Packing 6 or 8 Station Auto packing line.The equipment is mainly suitable for flour,starch,food, feed,medicine,rubber,fertilizer and other industries in powder materials and granules packed in different materials with continuously packaging.

www.immyhitech.com

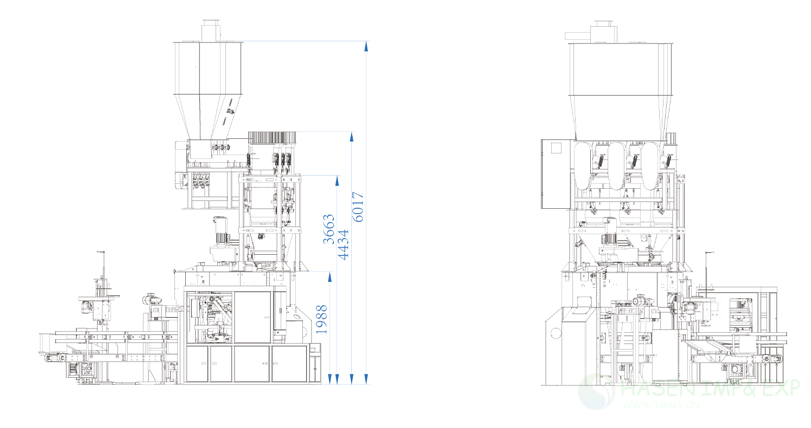

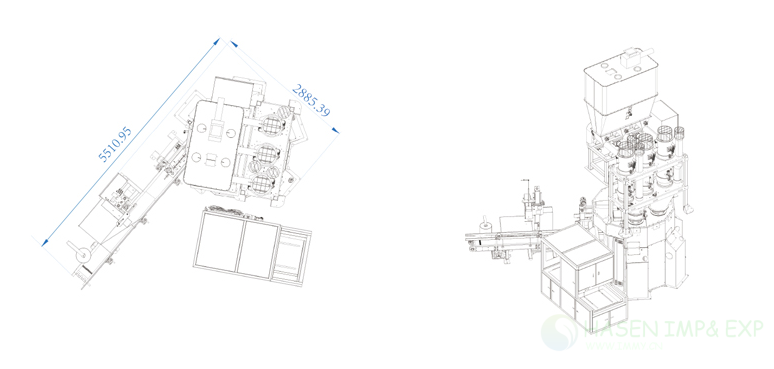

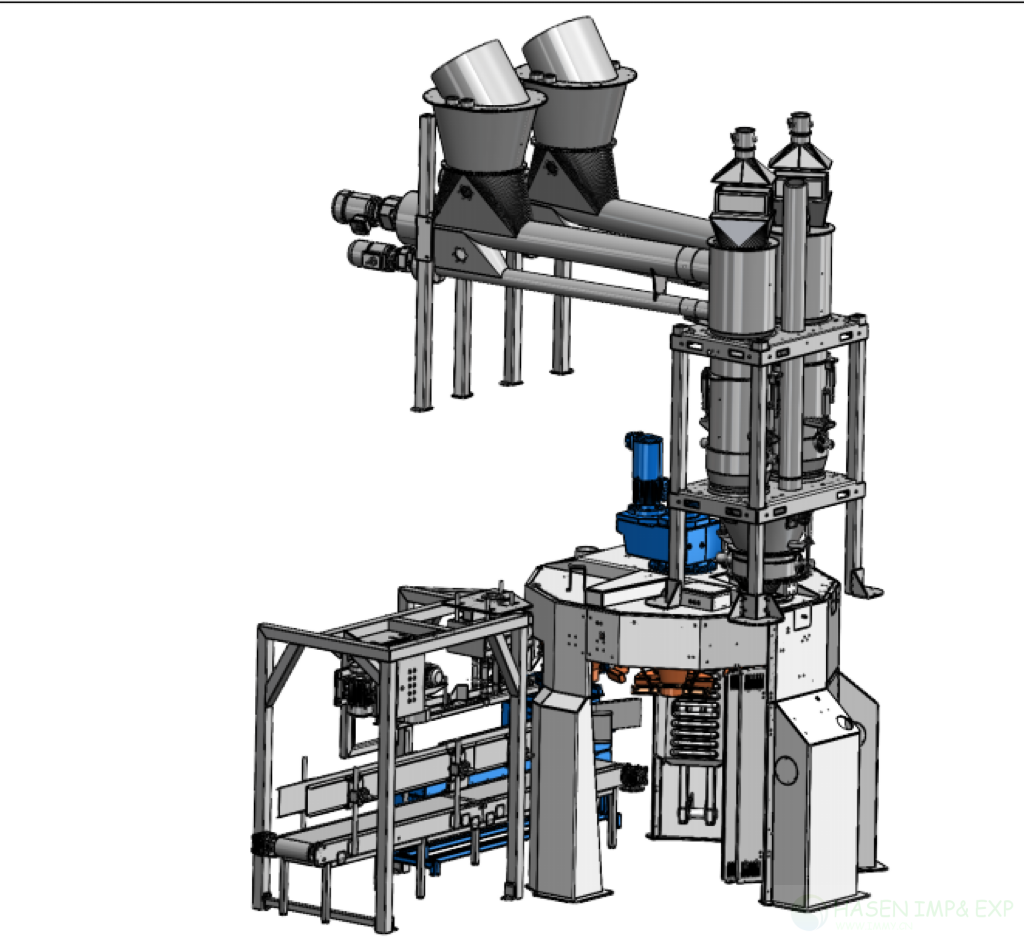

LCS series six-station automatic packaging scale is a multi-station high-efficiency automatic packaging scale independently developed and developed by us, which solves the problems of difficult employment, difficult management, low efficiency and large footprint. This equipment can improve fast packaging in the line and increase capacity efficiency. The equipment is mainly suitable for flour, starch, food, feed, medicine, rubber, fertilizer and other industries in powder materials and granules packed in different materials packaging. The main group of six-station automatic packaging scale.

MAIN COMPONENTS OF SIX STATIONAUTO PACKING SCALE:

1. Storage hopper on materials;

2. Multi-group feeding auger mechanism;

3. Weighing bucket combination mechanism;

4. Six-station turntable mechanism;

5. Three groups of vibrating bag machine mechanism;

6. Automatic seam part: whole edge machine, folding machine, sewing machine;

7. Automatic bagging machine part: bagging machine, bag warehouse;

8. Control system integration cabinet;

CONTROL SYSTEM PARTS:

1. This system can control the weighing of 2-way and 3-way combination at the same time, and control the servo motor feeding

2. All input and output interfaces are fully isolated, and the isolation voltage is 2500V;

3. High-speed and high-precision AD, accuracy 32 bits, speed 1000 times/per second per channel, temperature drift less than 5ppm;

4. With a variety of communication methods and network port communication:

Flour Packing 6 or 8 Station Auto packing line.The equipment is mainly suitable for flour,starch,food, feed,medicine,rubber,fertilizer and other industries in powder materials and granules packed in different materials with continuously packaging.

The Flour Packing 6 or 8 Station Auto packing line is a fully automated rotary packing system designed for high-efficiency and continuous packaging of powder and granular materials. A Flour Packing 6 or 8 Station Auto packing line typically integrates automatic weighing, filling, bag clamping, sealing, and discharge, ensuring consistent accuracy and reduced labor costs for modern production facilities.

A Flour Packing 6 or 8 Station Auto packing line is widely used in industries such as flour milling, starch processing, food production, animal feed, pharmaceuticals, rubber chemicals, and fertilizer manufacturing. Because the Flour Packing 6 or 8 Station Auto packing line can handle both powder materials and granules, it is suitable for multi-industry applications requiring hygienic and precise packaging solutions.

The Flour Packing 6 or 8 Station Auto packing line is capable of packaging wheat flour, corn flour, starch, spices, protein powder, feed additives, chemical powders, and granular products. With different feeding systems and bag materials, the Flour Packing 6 or 8 Station Auto packing line can adapt to paper bags, woven bags, PE bags, and laminated bags for diverse packaging requirements.

A Flour Packing 6 or 8 Station Auto packing line with 6 stations is ideal for medium-capacity production lines, offering stable output and compact layout. An 8-station Flour Packing 6 or 8 Station Auto packing line provides higher throughput and improved operational flexibility, allowing more processes to run simultaneously and increasing overall packing efficiency in large-scale factories.

The Flour Packing 6 or 8 Station Auto packing line uses high-precision load cells and intelligent control systems to ensure accurate weighing for each bag. Through automatic correction and real-time monitoring, the Flour Packing 6 or 8 Station Auto packing line minimizes material loss, improves consistency, and meets strict quality control standards across different industries.

The Flour Packing 6 or 8 Station Auto packing line is designed with a user-friendly HMI touch screen and PLC control system, making operation simple and intuitive. Routine cleaning and maintenance of the Flour Packing 6 or 8 Station Auto packing line are convenient due to modular design, accessible components, and durable construction suitable for long-term industrial use.

By automating the entire packaging process, the Flour Packing 6 or 8 Station Auto packing line significantly reduces manual labor and human error. Continuous rotary operation allows the Flour Packing 6 or 8 Station Auto packing line to maintain stable speed and high output, helping manufacturers meet increasing market demand while lowering operational costs.

Yes, the Flour Packing 6 or 8 Station Auto packing line can be customized according to bag size, material type, filling method, and production capacity. Whether integrating dust collection, sewing machines, or heat sealing units, the Flour Packing 6 or 8 Station Auto packing line can be tailored to fit specific factory layouts and product characteristics.

The Flour Packing 6 or 8 Station Auto packing line is equipped with safety interlocks, fault alarms, and emergency stop systems to ensure safe operation. Built with food-grade or industrial-grade materials, the Flour Packing 6 or 8 Station Auto packing line complies with hygiene and quality standards required in food, pharmaceutical, and chemical industries.

Choosing the right supplier is essential for long-term performance of a Flour Packing 6 or 8 Station Auto packing line, including installation, training, and after-sales service. For reliable solutions, advanced technology, and professional support, please contact with WUXI HASEN (www.immyhitech.com) For Flour Packing 6 or 8 Station Auto packing line.

#FlourPacking6Station

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000