Vibro Discharger.Feeding device installed under a bin bottom of flour mill processing line to prevent material bridging and ensure a consistent feeding rate.Used in grain,oil,animal feed mill,food,chemicals,pharmaceutical silos conveyor ETC industries.www.immyhitech.com

VIBRO DISCHARGER (Unloader)

Vibro Discharger.Feeding device installed under a bin bottom of flour mill processing line to prevent material bridging and ensure a consistent feeding rate.Used in grain,oil,animal feed mill,food,chemicals,pharmaceutical silos conveyor ETC industries.www.immyhitech.com

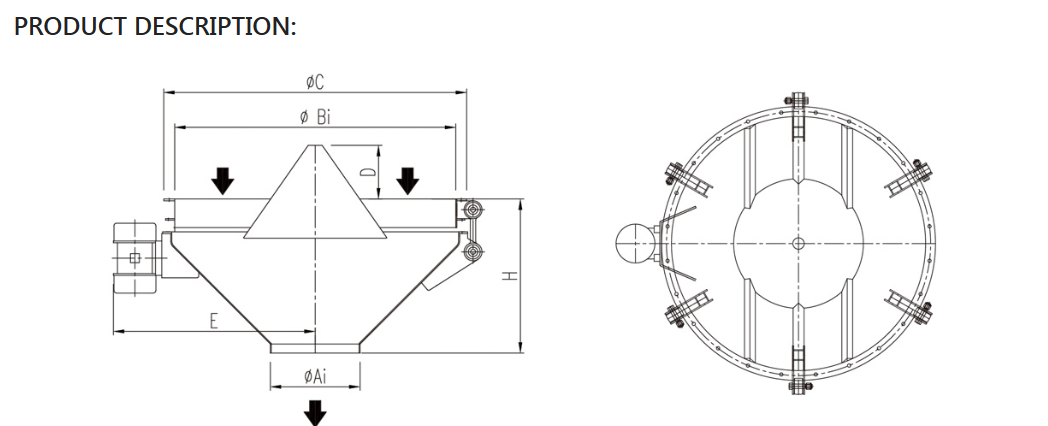

BOTTOM VIBRATION DISCHARGER (UNLOADER ) is a feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding

rate. Long service life silicon rubber seals ensures dust free operation. Different model designs are utilized for different products.

Bottom vibration discharger -( unloader) can achieve uniform unloading of bulk materials in concrete, steel and plastic bins. To ensure complete unloading of

round, square and rectangular silos without automatic grading.Used in flour, food, feed, com flour, wine, chemical, and other industries.

Application:

Vibration unloader can achieve uniform unloading of bulk materials in concrete, steel and plastic bins. To ensure

complete unloading of round, square and rectangular silos without automatic grading.

The mechanism is divided into two kinds of connecting rod torsion spring and spring.

Used in flour, food, feed, com flour, wine, chemical, and other industries.

There are two versions of stainless steel and carbon steel, you can choose different versions according to industry

attributes.

Features:

Integral spinning cone.

Provide single outlet and double outlet two versions

Available in torsion spring rod and spring rod versions.

Special silicone soft link pressed by flange is durable.

Bottom vibration unloader can achieve uniform unloading of bulk materials in concrete, steel and plastic bins. To ensure complete unloading of round, square and rectangular silos without automatic grading.

Discharging Disk: A conical discharging disk locates at the center part of discharging hopper, it pushes the material discharging slowly and uniformly from the outlet, meanwhile, it can prevent the material from blocking.

.jpg)

The VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line is a mechanical vibrating unit designed to improve bulk material flow from bins and silos. By generating controlled vibration, the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line breaks arches, eliminates rat-holing, and promotes uniform discharge. This ensures that powders, granules, and semi-free-flowing materials move steadily into downstream conveyors or processing equipment. The VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line is widely used where precise and reliable feeding is essential.

In flour mills, maintaining uniform material flow is critical, and the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line plays a key role in achieving this goal. Flour tends to compact and bridge due to fine particle size and moisture, which can interrupt production. The VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line prevents stoppages by continuously loosening the stored material. With stable discharge, the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line improves product quality and operational efficiency.

The VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line is not limited to flour milling and is widely adopted across many industries. Grain storage facilities, oilseed processing plants, animal feed mills, food factories, chemical plants, and pharmaceutical industries all rely on the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line to maintain uninterrupted material flow. In silo and conveyor systems, the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line ensures smooth feeding into mechanical or pneumatic conveying equipment.

Material bridging and rat-holing are common problems in bulk storage, and the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line directly addresses these issues. By applying low-amplitude, high-frequency vibration, the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line disrupts cohesive forces within the material. This keeps the product loose and flowing evenly. As a result, the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line significantly reduces downtime and manual intervention.

Yes, one of the major advantages of the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line is its ability to maintain a stable and predictable discharge. Consistent feeding is crucial for batching, weighing, and continuous processing systems. The VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line provides uniform material flow, which improves downstream process accuracy. By stabilizing flow conditions, the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line enhances productivity and reduces waste.

The VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line is designed to meet the hygienic and operational requirements of food and pharmaceutical industries. Constructed with food-grade materials and smooth surfaces, the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line minimizes contamination risks. In pharmaceutical silos, precise dosing is critical, and the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line ensures reliable and repeatable material discharge.

The VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line is engineered for easy installation beneath existing bin or silo outlets. Its compact design allows integration without major structural changes. Maintenance requirements for the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line are minimal, as it has few moving parts. With proper use, the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line delivers long service life and reliable performance.

WUXI HASEN provides high-quality solutions, and their VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line is engineered for durability and efficiency. With extensive industry experience, WUXI HASEN designs the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line to meet diverse material handling challenges. Customers worldwide trust the VIBRO DISCHARGER (Unloader) Feeding device installed under a bin bottom to prevent material bridging and ensure a consistent feeding rate in flour processing line for consistent performance and competitive cost.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000