Indented cylinder separator is a grain cleaning and grading machine used in grain(wheat maize, rice mill),oat and barkey,millet,oil seeds, peas,beans,coffees,feed:www.immyhitech.com

Our INDENTED CYLINDER SEPARATOR FGJZ series cylinder separator is a grain cleaning and grading machine used in grains: wheat,barley,rice,corn,rice,oat,millet,oil seeds,peas,beans,coffees etc. It removes impurities which shorter or longer than you wanted grains, as well as classify the grains according to their lengths.www.immyhitech.com

Our INDENTED CYLINDER SEPARATOR FGJZ series indented cylinder is a grain cleaning and grading machine in all granular grains materials like wheat, barley, rice,corn, oat, millet,oil seeds,peas,beans,coffees,lentils, stones from peas, sticks from sunflower or sugar beet, plastic particles etc., as well as for the extraction of unwanted

short or long admixtures.

It removes impurities which shorter or longer than you wanted grains, as well as classify grains according to their lengths.

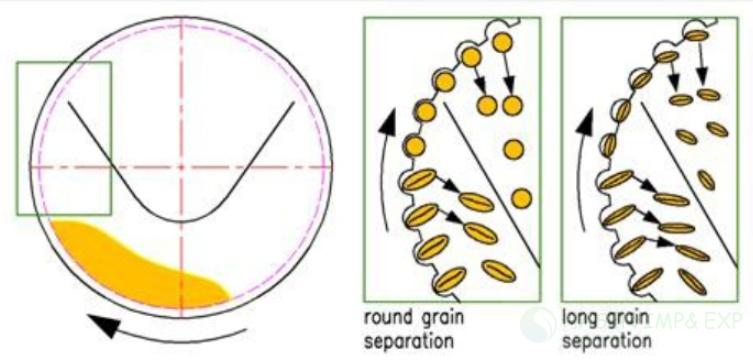

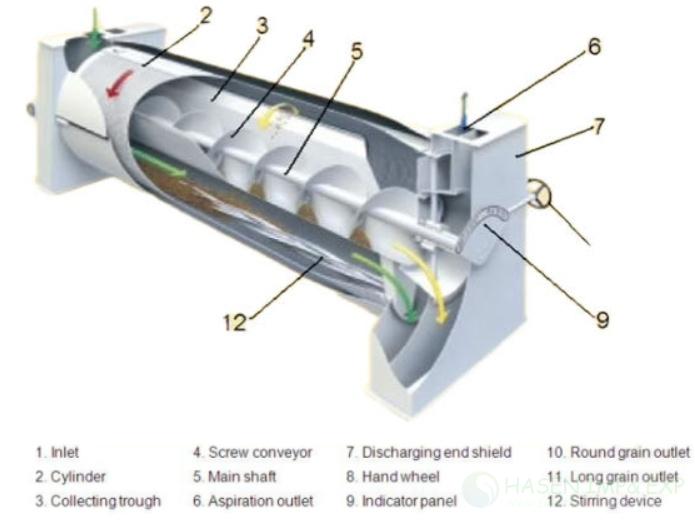

INDENTED CYLINDER SEPARATOR material is fed at a uniform rate through the inlet directly into the rotating cylinder. As a result of the indented pockets in the jacket, the material particles that can be accommodated in the pockets are elevated and thrown into the collection trough.

The material in the trough is then discharged from the machine by a conveying screw; the material remaining inside the jacket or dropping back into it flows via the guiding device to the outlet of the Indented Separator.

Cylinder

Customized according to different requirements

INDENTED CYLINDER SEPARATOR FGJZ series cylinder separator is a grain cleaning and grading machine used in grains: wheat,barley,rice,corn,rice,oat,millet,oil seeds,peas,beans,coffees etc. It removes impurities which shorter or longer than you wanted grains, as well as classify the grains according to their lengths.www.immyhitech.com

Pockets on Cylinder

High efficient to separate materials according to different size

The separating efficiency of the machine can be controlled both by the selection of the pocket size and by adjustment of the separating trough (position of the trough rim).

The high separating efficiency of the Indented Separator is further promoted by the adjustable retarding device installed in the cylindrical section of the Long-grain Separator.

Aspiration connections at the important points of the Indented Separator ensure the dust-free operation of the machine.

Feature

1. This machine can effectively remove both the short and long impurities.

2. The modular design of the components and versatile feeding device make the cylinders change conveniently between series connection and parallel connection.

3. The cylinder is made of highly anti-wear material, so its service life is quite long.

4. The indented cylinder can be detached into two parts, and come with a rapid assembling device. Thus the operators can quickly and easily change the cylinders.

5. The indents are processed with a composite forming technique. The surface of the indented sieve is blunted, thus both the quality and durability can be improved.

INDENTED CYLINDER SEPARATOR

Optional equipment

On request the machine can be equipped with:

• Pocket air cleaning system

• Adjustable cylinder inclination

• Stirring device

• Wear resistant lining

• Adjustable speed

• Automatic trough adjustment

1. What is an Indented Cylinder Separator FGJZ series cylinder separator?

The Indented Cylinder Separator FGJZ series cylinder separator is a precision grain cleaning and grading machine designed to separate grains and seeds based on length differences. It is widely used in grain processing plants, seed cleaning lines, flour mills, rice mills, feed mills, and agricultural processing facilities. The machine efficiently removes impurities that are either shorter or longer than the target grain and can also classify grains into different length grades.

2. How does the Indented Cylinder Separator FGJZ series work?

The working principle of the FGJZ series indented cylinder separator is based on length selection. The rotating indented cylinder contains precisely engineered pockets (indents).

Shorter grains or broken kernels fit into the indents and are lifted as the cylinder rotates.

At a specific height, these particles fall into a collecting trough.

Longer grains and impurities remain outside the indents and are discharged separately.

This mechanical process ensures accurate grain length separation without damaging the product.

3. What grains can be processed using the FGJZ series cylinder separator?

The Indented Cylinder Separator FGJZ series cylinder separator is highly versatile and suitable for a wide range of agricultural products, including:

Wheat

Barley

Rice

Corn (maize)

Oats

Millet

Oil seeds

Peas

Beans

Coffee beans

This flexibility makes the FGJZ series an essential machine in multi-grain processing facilities.

4. What types of impurities does the FGJZ series remove?

The FGJZ series cylinder separator removes impurities that differ in length, including:

Broken grains

Short kernels

Long straw fragments

Unhulled grains

Long weed seeds

Oversized foreign materials

It is particularly effective when used after initial cleaning equipment such as vibrating screens or air separators.

5. Why is length-based separation important in grain processing?

Length-based separation is critical for improving grain purity, uniformity, and market value. The Indented Cylinder Separator FGJZ series ensures:

Higher product quality

Consistent grain size for milling

Reduced wear on downstream equipment

Improved seed grading accuracy

This is especially important for seed processing, where uniform length impacts planting performance and germination.

6. What are the main applications of the FGJZ series cylinder separator?

The FGJZ series indented cylinder separator is commonly used in:

Grain cleaning plants

Flour mills

Rice milling lines

Seed processing facilities

Feed mills

Coffee bean processing plants

It can be used as a standalone unit or integrated into a complete grain cleaning and grading system.

7. What are the advantages of the Indented Cylinder Separator FGJZ series?

Key advantages include:

High separation accuracy

Stable and continuous operation

Adjustable rotation speed

Low grain breakage rate

Energy-efficient design

Easy operation and maintenance

These advantages make the FGJZ series a reliable solution for both large-scale and medium-scale grain processors.

8. Can the FGJZ series classify grains by length?

Yes. In addition to impurity removal, the Indented Cylinder Separator FGJZ series cylinder separator can classify grains into different length categories. By adjusting cylinder parameters and collection trough positions, operators can separate grains into multiple grades, which is ideal for seed selection and premium grain processing.

9. Is the FGJZ series suitable for seed cleaning?

Absolutely. The FGJZ series is widely used in seed cleaning and grading due to its gentle handling and precise length separation. It helps remove broken seeds, immature kernels, and foreign materials without affecting seed viability.

10. How is the FGJZ series adjusted for different grains?

The machine can be adapted by:

Selecting different indented cylinder sizes

Adjusting cylinder rotation speed

Modifying feed rate

Changing trough positions

These adjustments allow the Indented Cylinder Separator FGJZ series to handle different grains such as wheat, rice, corn, and coffee beans efficiently.

11. Does the FGJZ series damage grains during processing?

No. The FGJZ series cylinder separator is designed for gentle mechanical handling. The separation process relies on gravity and rotation rather than impact, minimizing grain breakage and preserving product quality.

12. What makes the FGJZ series different from other grain separators?

Unlike sieves or gravity separators, the Indented Cylinder Separator FGJZ series focuses exclusively on length-based separation, making it uniquely effective for removing broken or elongated impurities that other machines may miss.

13. Is the FGJZ series easy to maintain?

Yes. The FGJZ series features:

Durable construction

Simple mechanical structure

Easy access for cleaning and inspection

Long service life

Routine maintenance ensures consistent performance and minimal downtime.

14. Can the FGJZ series be integrated into an existing grain cleaning line?

Yes. The Indented Cylinder Separator FGJZ series cylinder separator is designed for seamless integration with pre-cleaners, destoners, gravity separators, and packaging systems. It enhances overall cleaning efficiency when used as part of a complete processing line.

15. What industries benefit most from the FGJZ series?

Industries that benefit include:

Grain trading and storage

Agricultural cooperatives

Seed production companies

Food processing plants

Coffee processing facilities

The machine helps meet quality standards required for domestic and export markets.

16. How does the FGJZ series improve grain market value?

By removing broken, short, and long impurities, the FGJZ series improves:

Grain appearance

Uniformity

Milling efficiency

End-product quality

This leads to higher selling prices and better customer satisfaction.

17. Is the FGJZ series energy efficient?

Yes. The Indented Cylinder Separator FGJZ series is designed for low power consumption while maintaining high separation efficiency, making it suitable for continuous industrial operation.

18. Can the FGJZ series process coffee beans?

Yes. The FGJZ series is effective for coffee bean length grading, helping remove broken beans and long impurities, resulting in consistent bean size for roasting and export quality control.

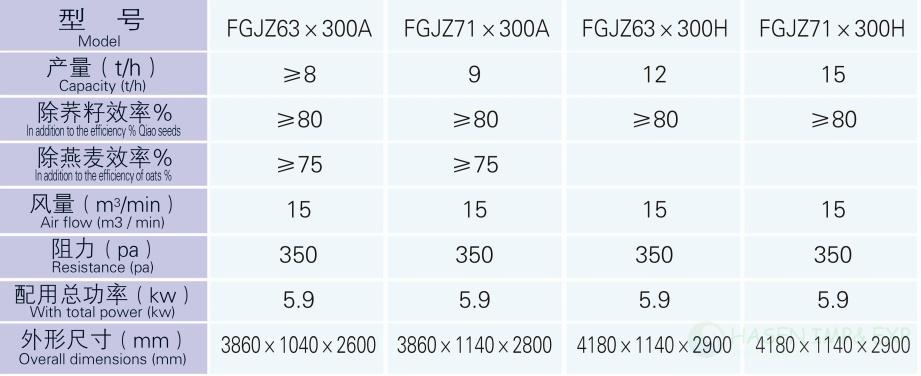

19. What capacity options are available for the FGJZ series?

The FGJZ series is available in multiple models with varying capacities to suit small, medium, and large-scale grain processing requirements. Capacity selection depends on grain type, moisture content, and cleaning objectives.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000