Magnetic Separator Separating magnetic metal inclusions in raw materials, iron removal in feed,grain,oil processing plants. www.immyhitech.com

Magnetic Separator Separating magnetic metal inclusions in raw materials, iron removal in feed,grain,oil processing plants. www.immyhitech.com

A magnetic separator is an industrial device designed to separate ferrous and magnetic metal contaminants from bulk materials. It works by generating a magnetic field that attracts iron particles, steel fragments, and other magnetic inclusions, removing them from raw materials during processing. Magnetic separators are essential in industries where product purity, equipment protection, and safety are critical, such as feed, grain, and oil processing plants.

Magnetic metal inclusions are commonly introduced into raw materials during harvesting, transportation, storage, or mechanical processing. These contaminants can damage downstream equipment, reduce product quality, and pose serious safety risks. Magnetic separator systems ensure effective iron removal, protecting machinery such as crushers, extruders, mills, and presses, while also maintaining consistent product standards.

Magnetic separators can remove a wide range of contaminants, including:

Iron filings and dust

Steel fragments and bolts

Nails, screws, and metal shavings

Tramp iron from agricultural or industrial sources

Advanced high-intensity magnetic separators can also capture weakly magnetic particles, ensuring thorough separation even in fine or powdery materials.

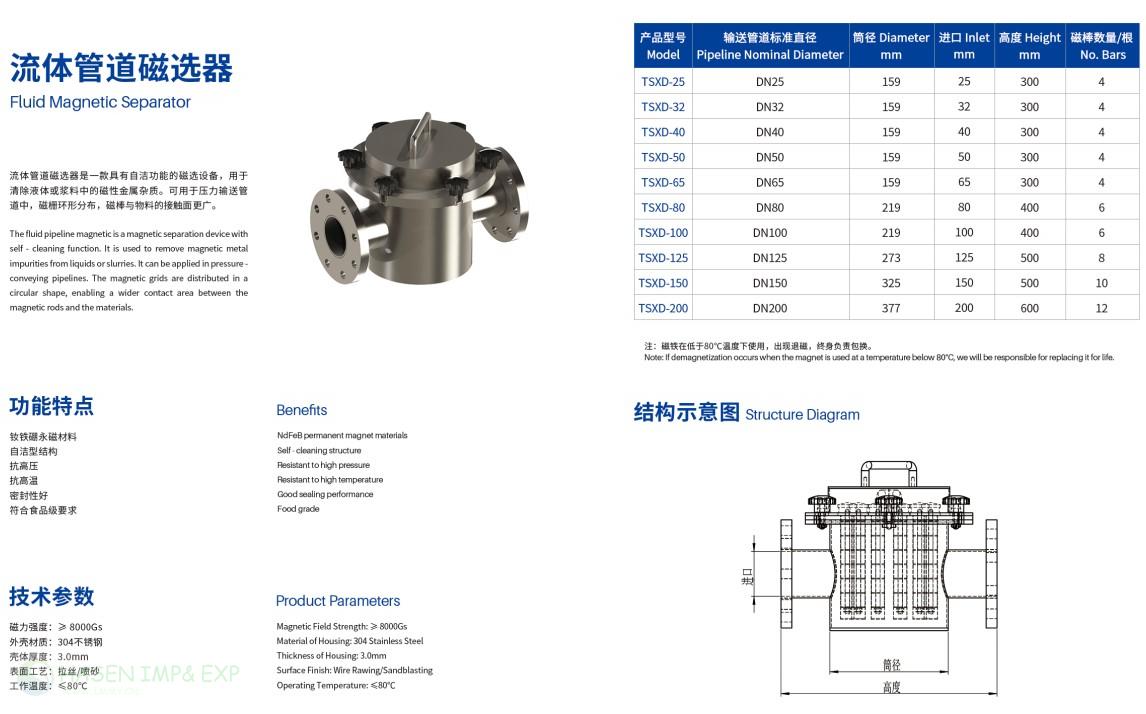

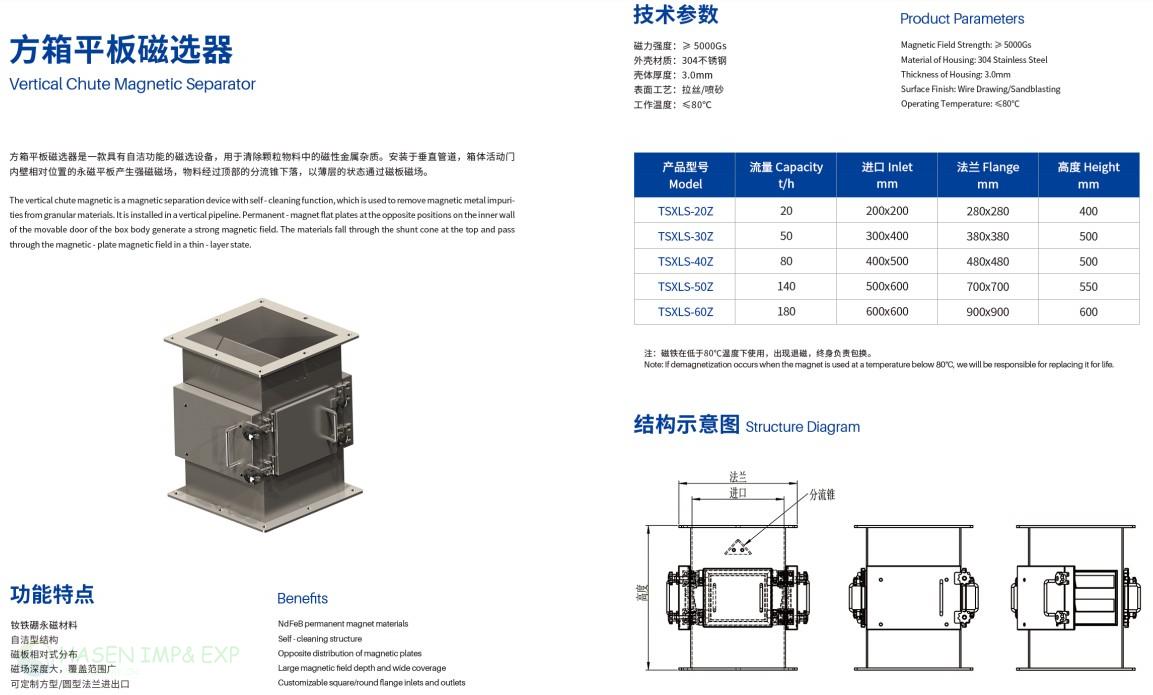

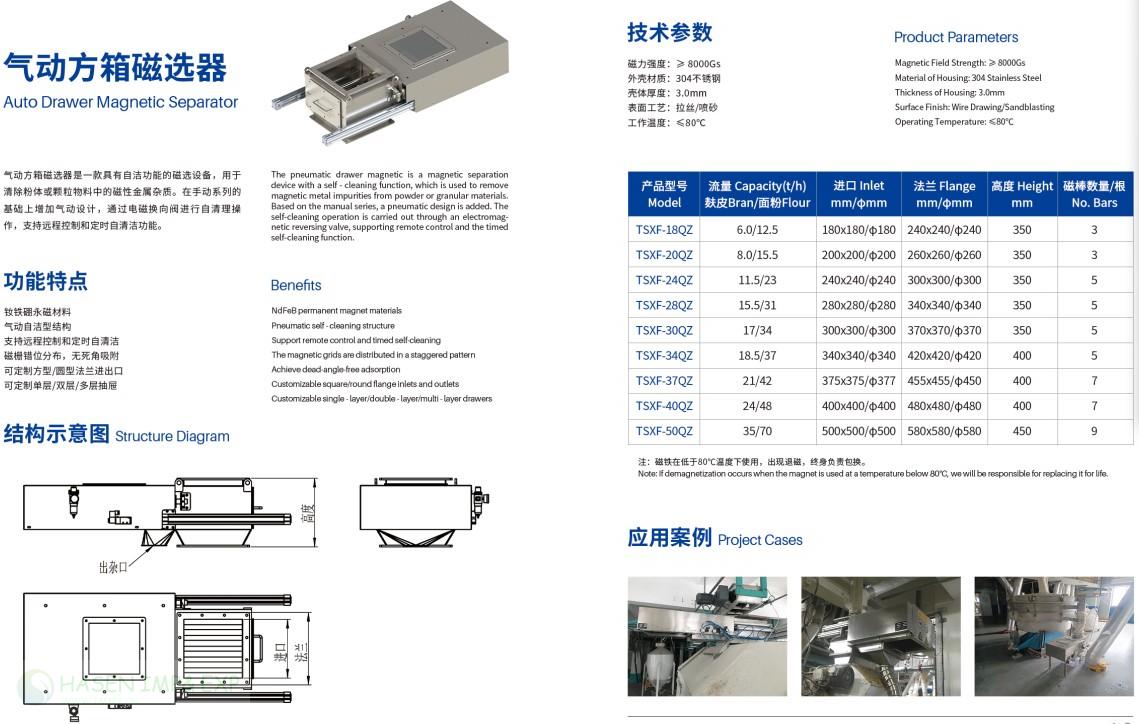

A magnetic separator works by exposing material flow to a controlled magnetic field. When raw materials pass through or over the magnetic system, ferrous contaminants are attracted and held by the magnet, while non-magnetic material continues along the processing line. Depending on the design, the captured metal can be removed manually or automatically, ensuring continuous operation with minimal downtime.

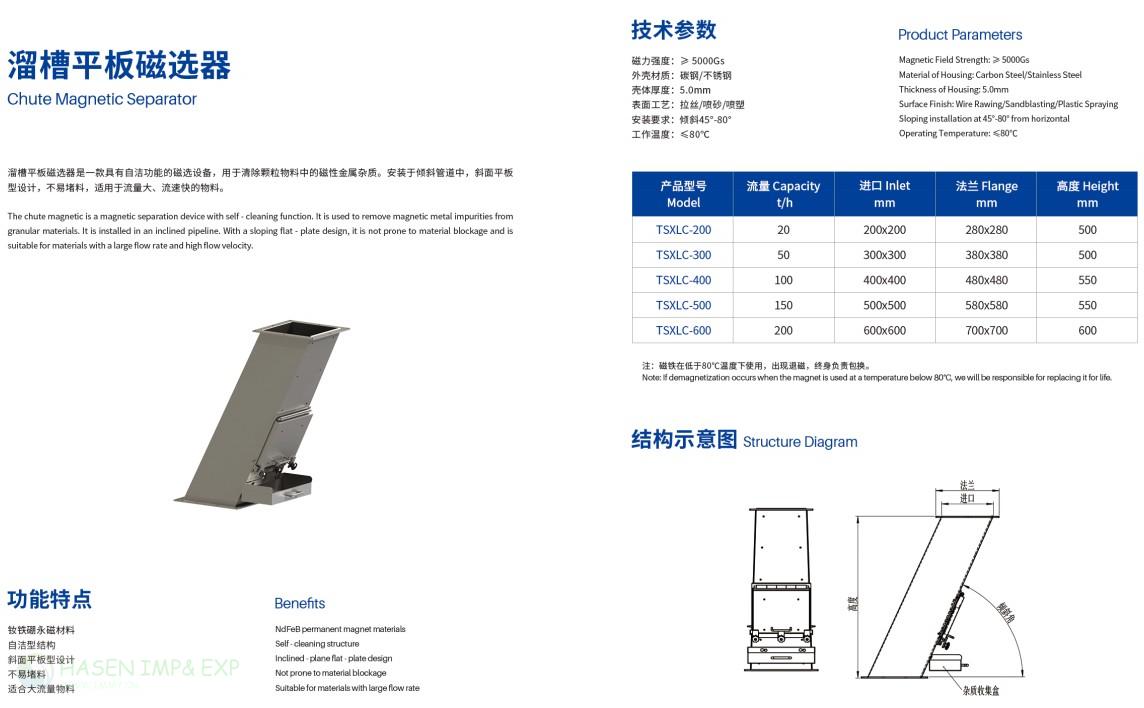

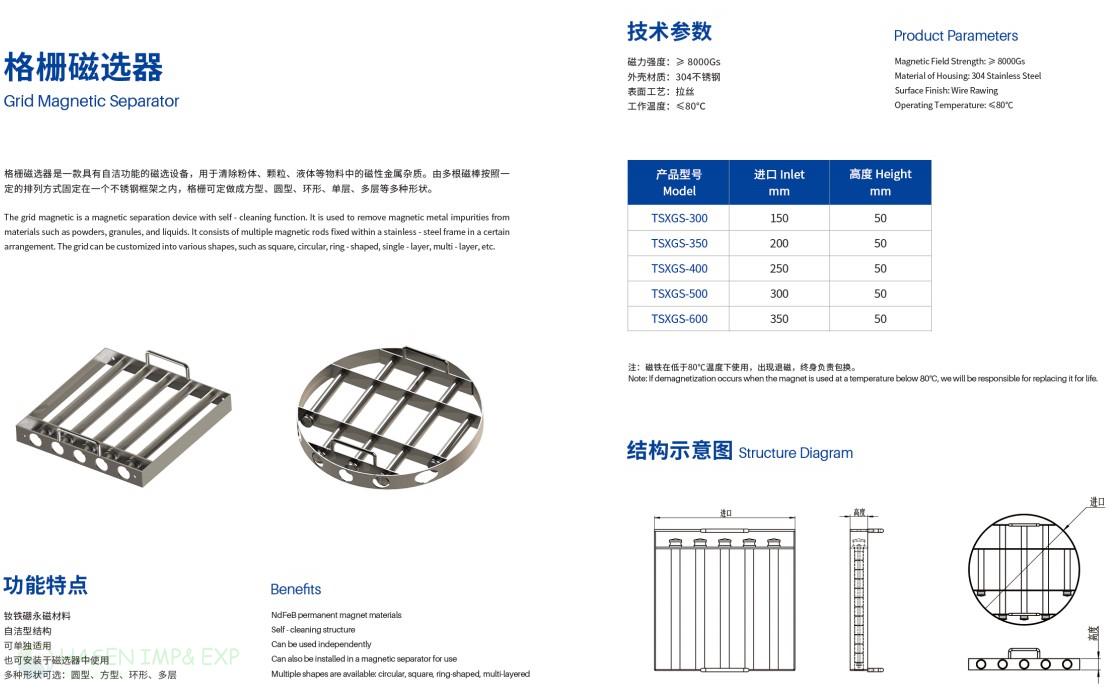

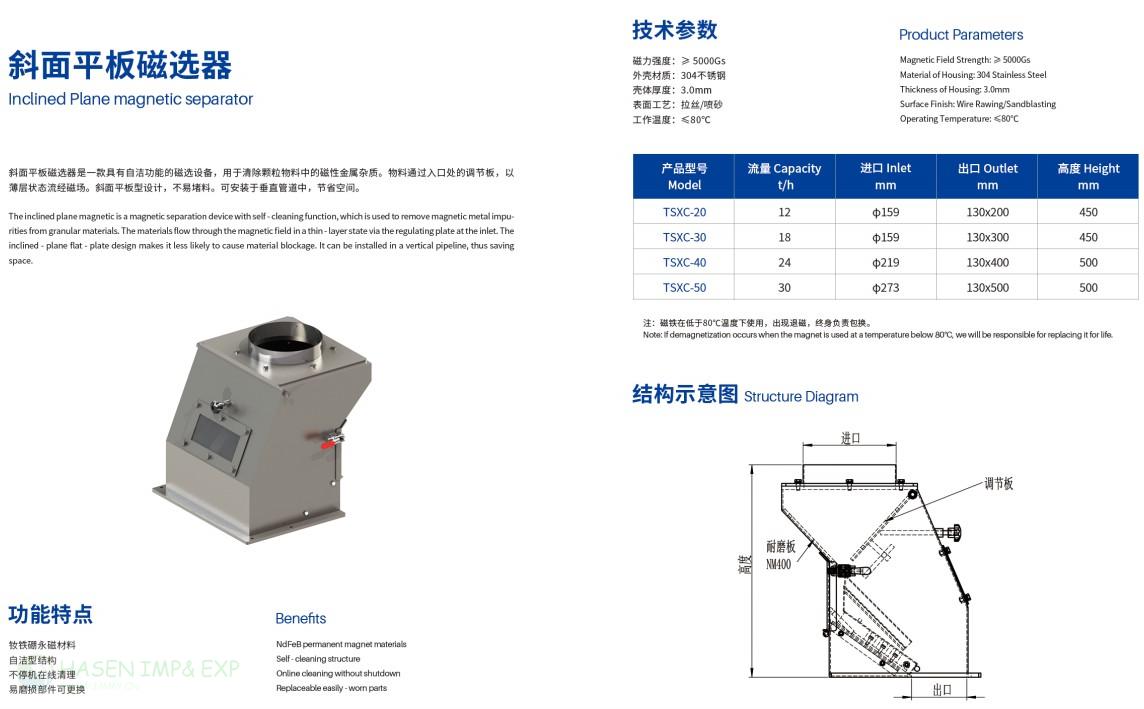

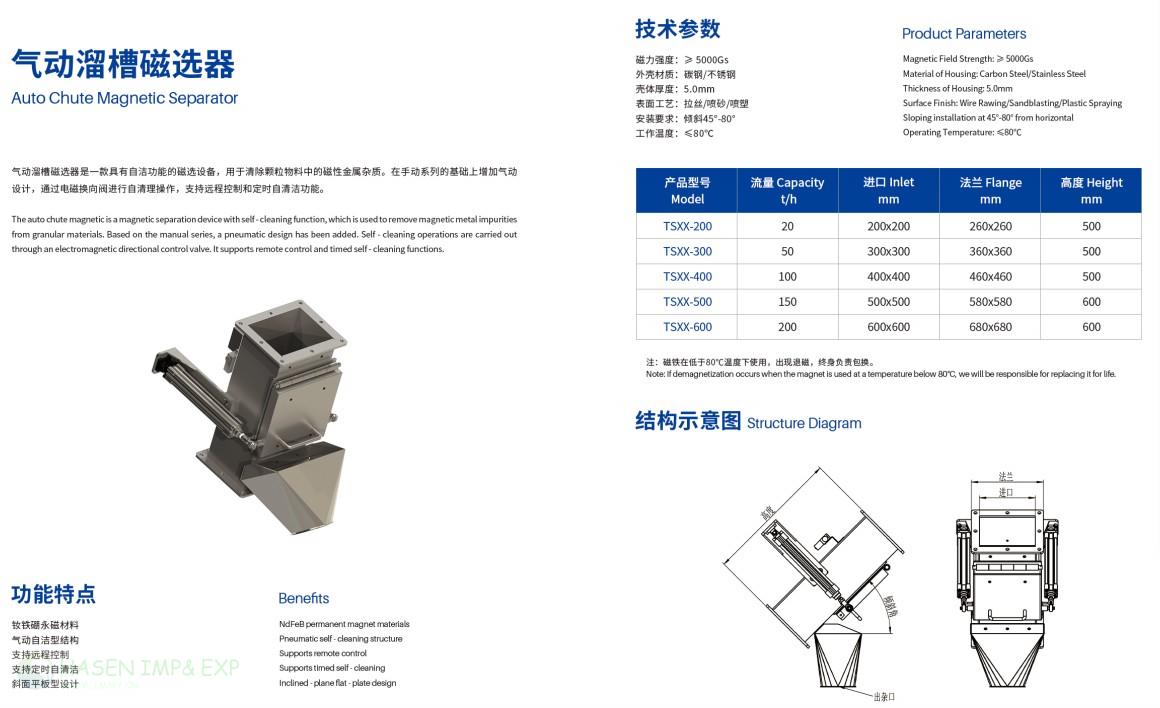

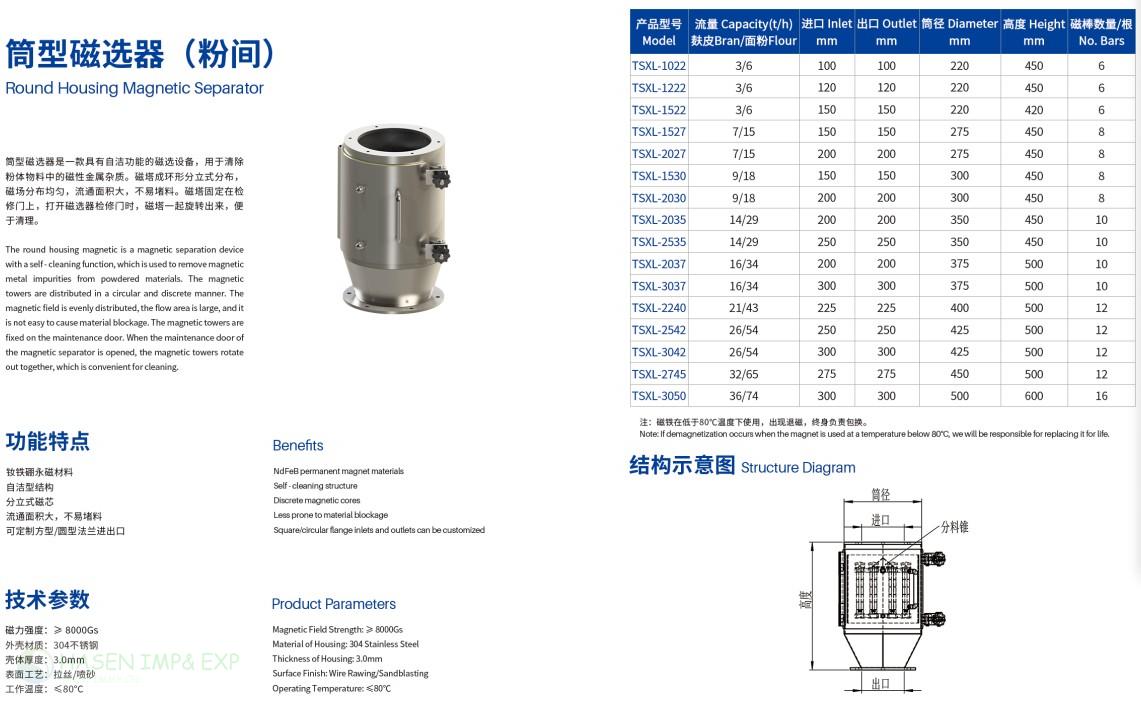

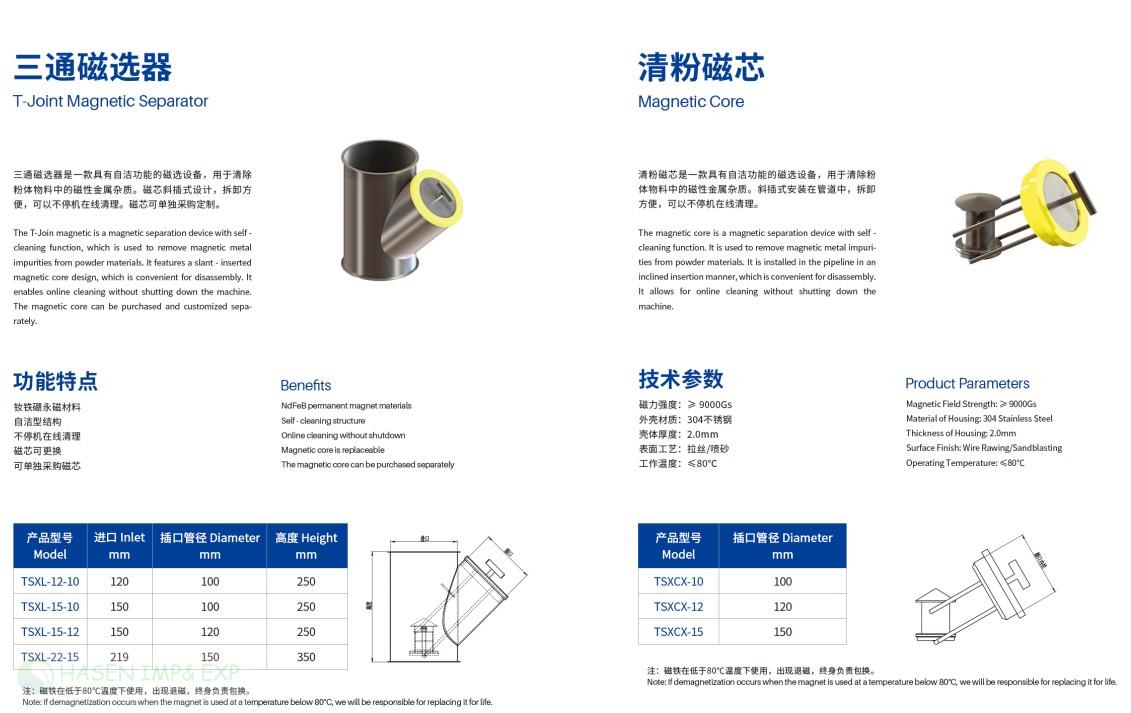

Feed processing plants commonly use several types of magnetic separators, including:

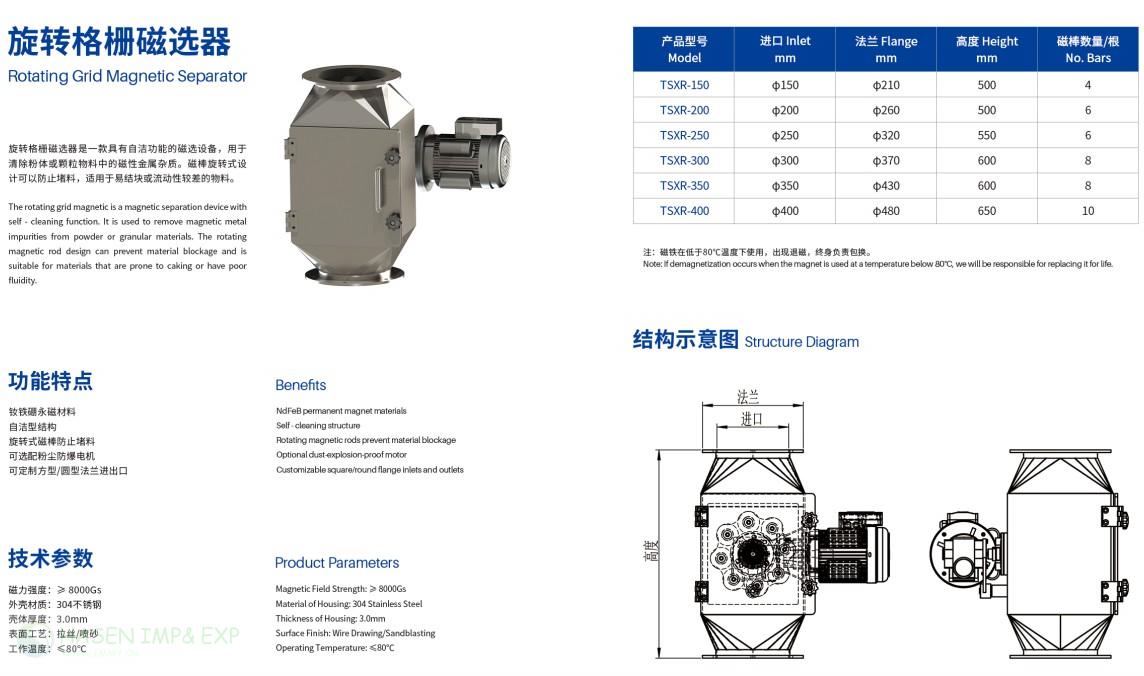

Magnetic grate separators for bins and hoppers

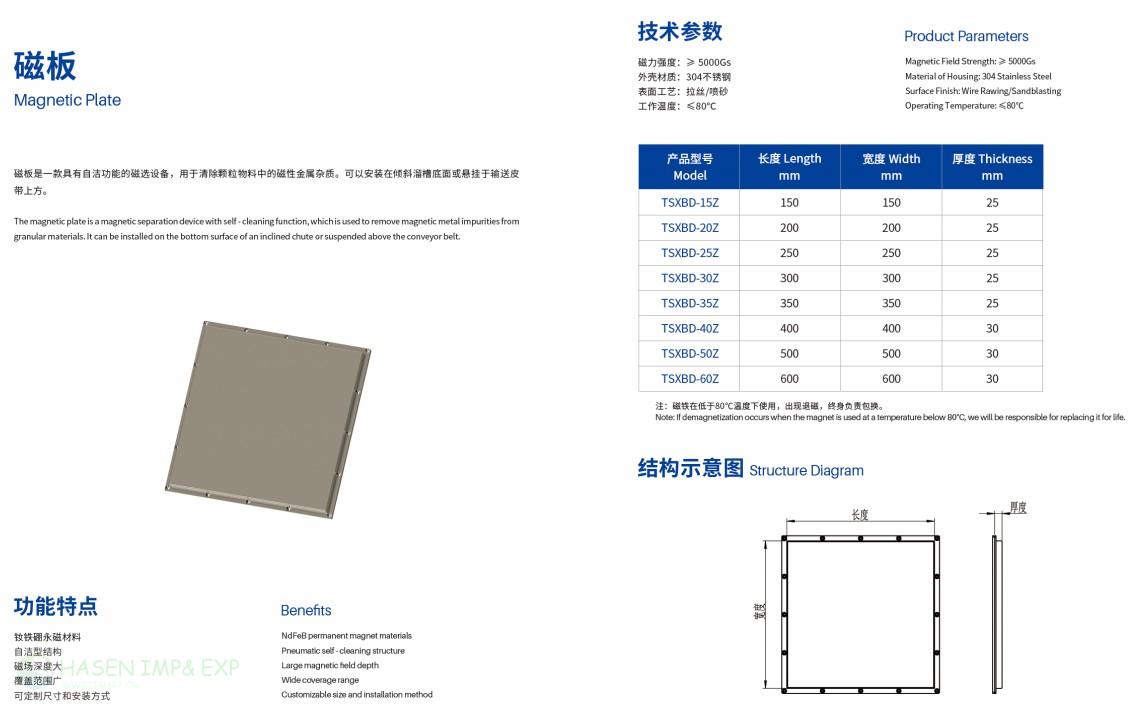

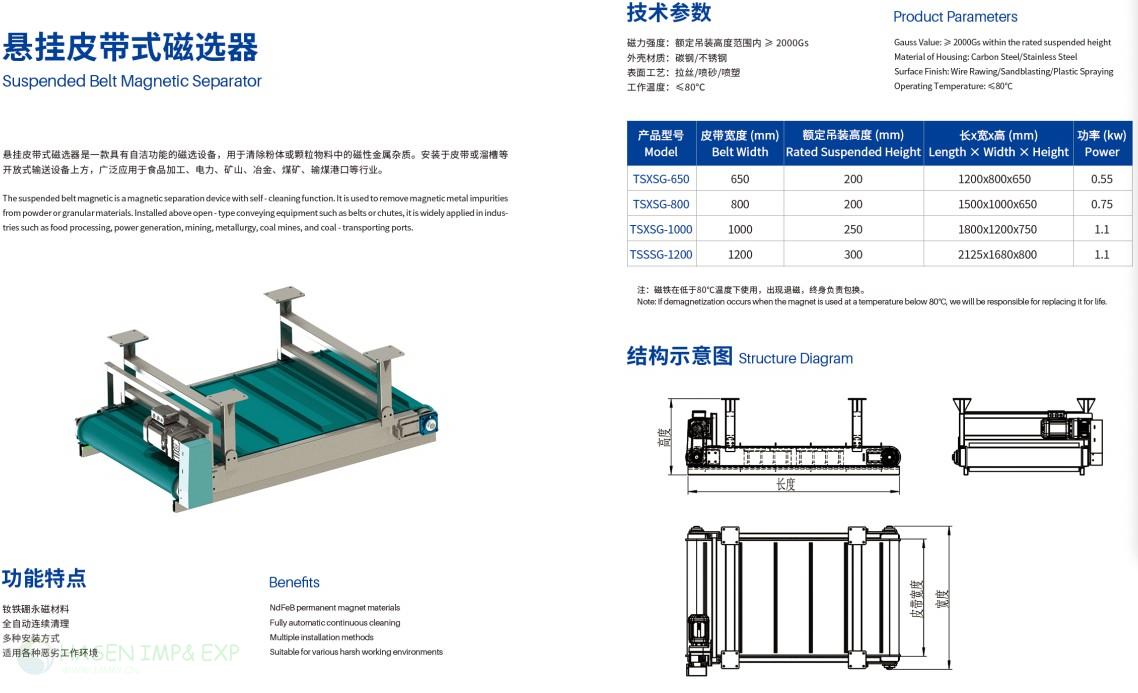

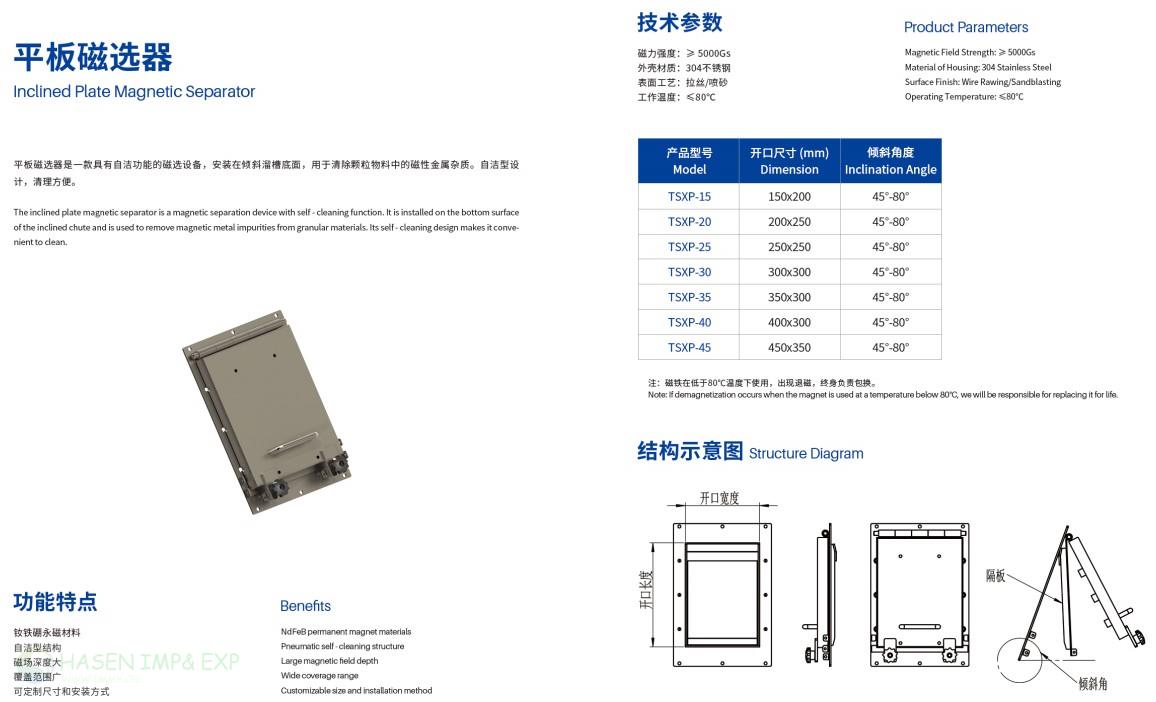

Plate magnets for conveyor belts

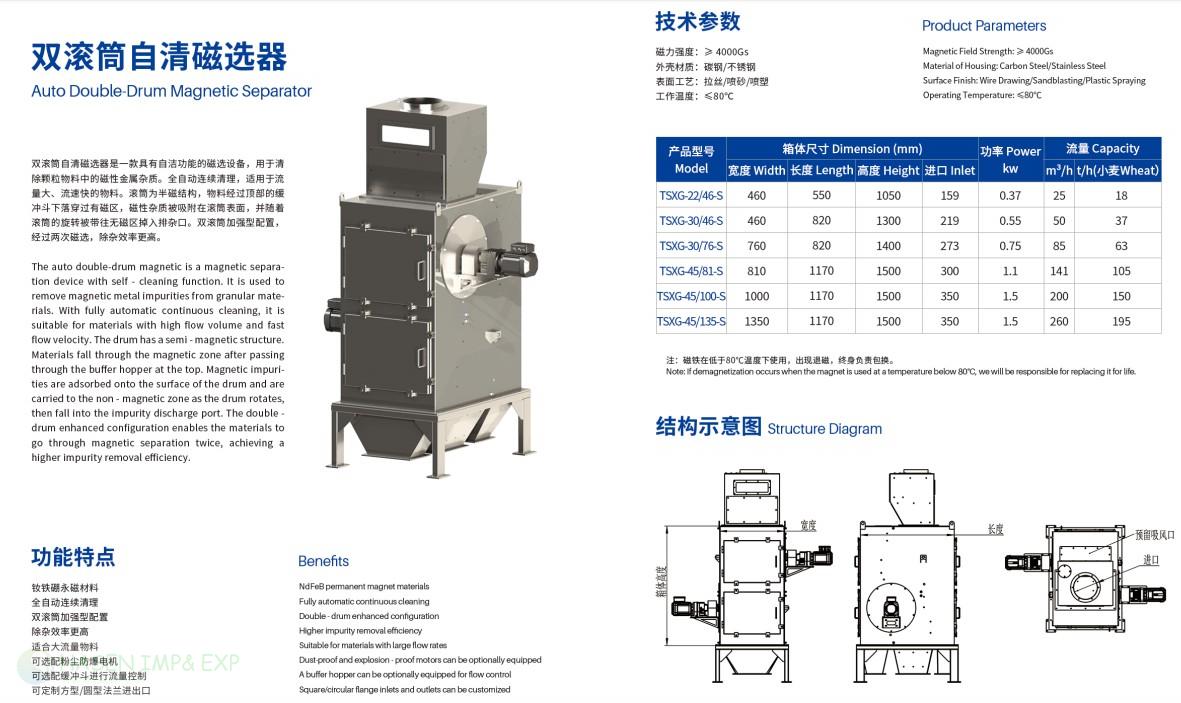

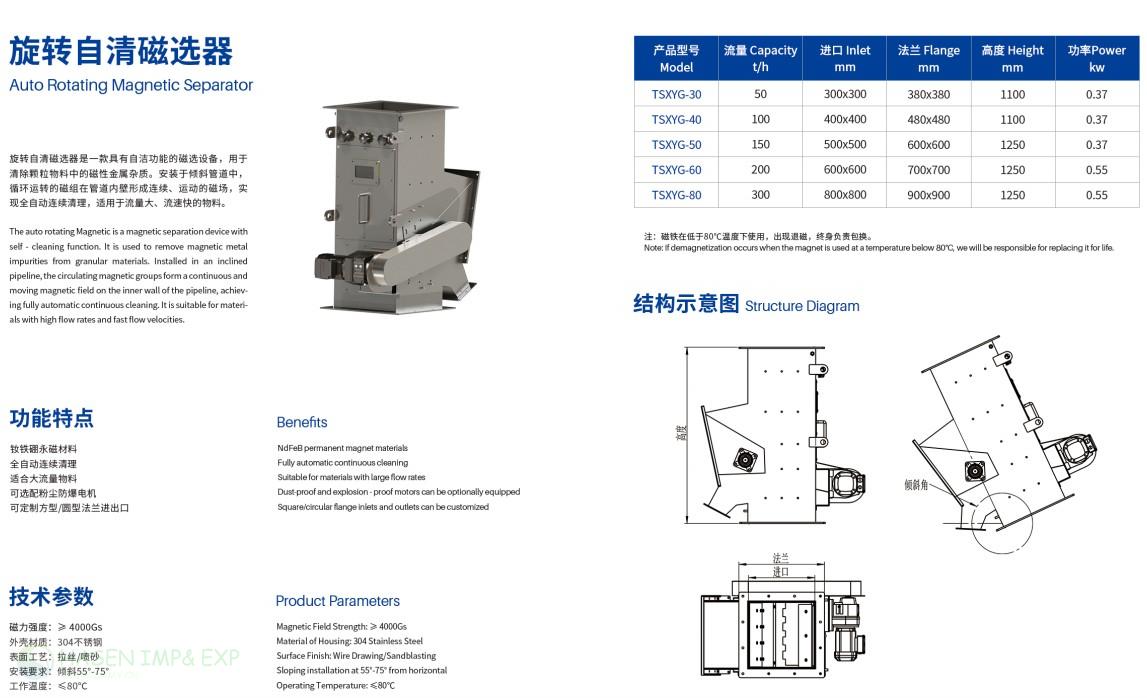

Drum magnetic separators for high-volume material flow

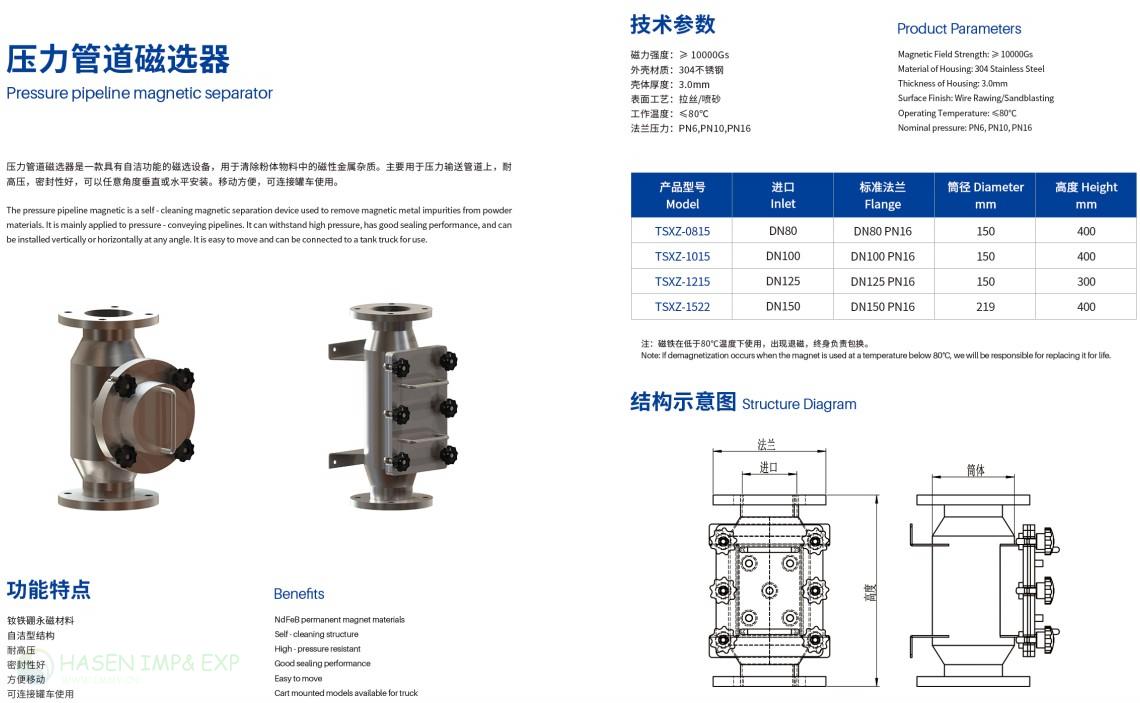

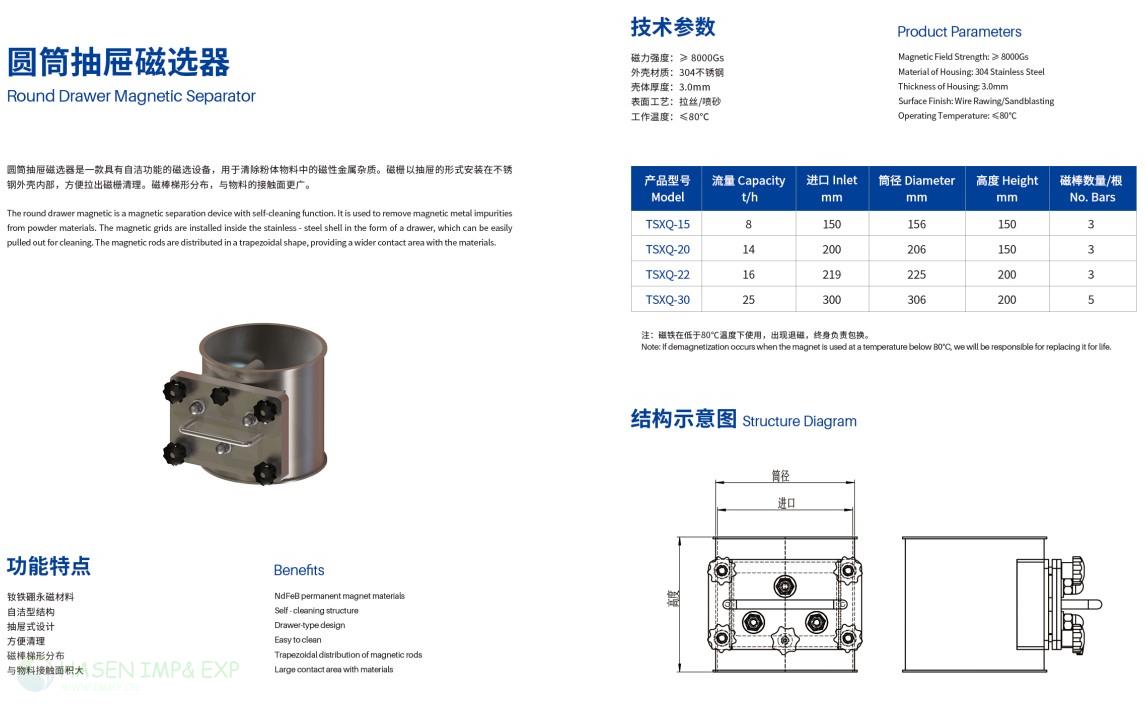

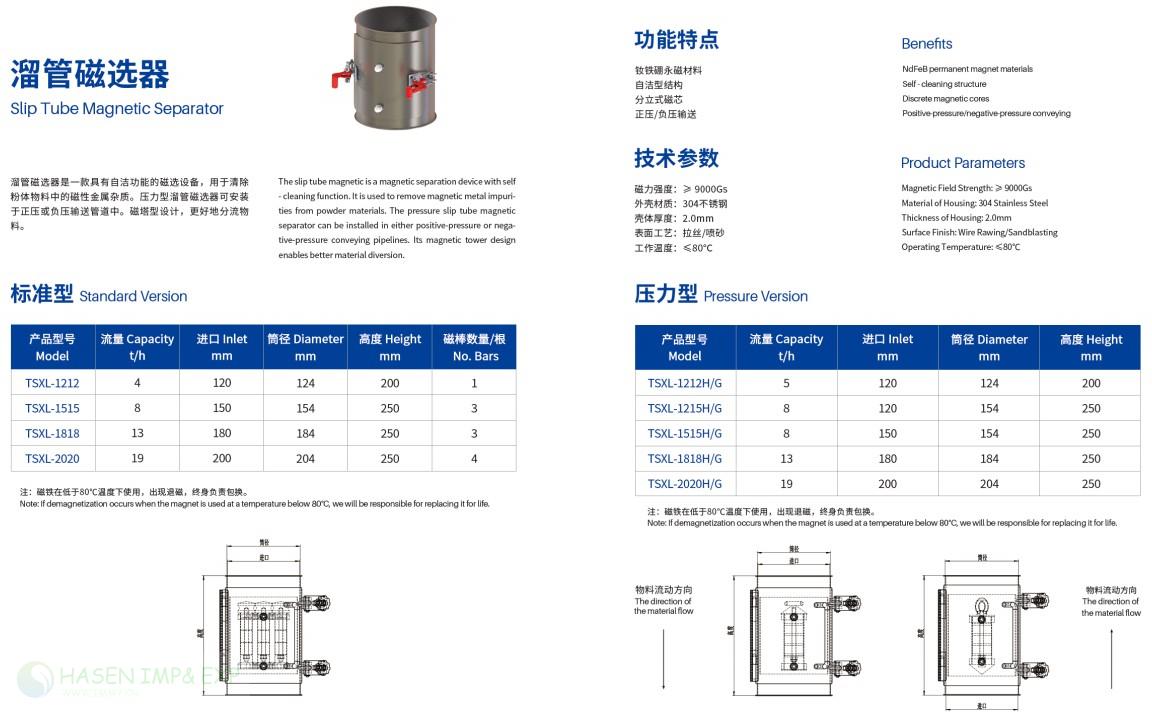

Pneumatic line magnetic separators for powdered feed

These systems help ensure iron removal in feed, preventing contamination that could harm livestock or damage pellet mills.

In grain processing plants, magnetic separators are used to remove iron impurities from wheat, corn, rice, barley, and other grains. During cleaning, conveying, and milling stages, tramp metal may be present due to harvesting machinery or storage silos. Magnetic separation improves food safety, protects grinding equipment, and helps comply with food quality regulations.

Oil processing plants, including edible oil and industrial oil production, rely heavily on magnetic separators to remove iron particles from oilseeds, flakes, and meal. Metal contaminants can damage presses, expellers, and filtration systems. Efficient iron removal improves oil purity, extends equipment life, and reduces maintenance costs, ensuring stable and hygienic production.

The main benefits include:

Improved product purity and quality

Protection of downstream equipment

Reduced equipment downtime and repair costs

Enhanced safety for workers and end users

Compliance with food and feed industry standards

Magnetic separator systems are a cost-effective solution with long service life and minimal operating costs.

Selecting the right magnetic separator depends on several factors:

Type and size of raw material

Material flow rate and processing method

Level and type of magnetic contamination

Installation position (conveyor, hopper, pipeline)

Cleaning method (manual or automatic)

Professional suppliers can customize solutions to match specific feed, grain, or oil processing requirements.

Yes. Many modern magnetic separators are designed for continuous operation, especially in large-scale industrial plants. Automatic cleaning magnetic separators allow uninterrupted material flow while removing captured metal contaminants, making them ideal for high-capacity feed mills, grain silos, and oil extraction plants.

Maintenance frequency depends on contamination levels and operating conditions. In high-risk environments, daily inspection may be required. Automatic self-cleaning magnetic separators significantly reduce manual maintenance. Regular inspection ensures optimal magnetic strength and consistent separation performance.

Absolutely. Magnetic separators play a crucial role in meeting food safety and feed quality standards by preventing metal contamination. Their use supports compliance with HACCP, GMP, and other international quality control systems, protecting both consumers and producers.

High-quality magnetic separators are built with durable materials and powerful permanent magnets, offering a long operational lifespan—often exceeding 10 years with proper maintenance. They provide excellent return on investment due to low energy consumption and minimal wear.

Yes. Many manufacturers provide customized magnetic separator solutions tailored to specific plant layouts, material characteristics, and production capacities. Custom designs ensure maximum efficiency in separating magnetic metal inclusions in raw materials across diverse industrial applications.

A professional manufacturer offers:

Reliable magnetic performance

Industry-specific design expertise

Customization options

After-sales technical support

Compliance with international standards

Choosing an experienced supplier ensures long-term performance and operational reliability.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000