Scraper Conveyor for grain,oil,food,wheat,feed,chemical,metallurgy,variety of raw materials, semi finished products such as particles or powder level and tilt transportation:www.immyhitech.com

SCRAPER CONVEYOR for grain,oil,food,wheat,feed,chemical,metallurgy,variety of raw materials,semi finished products. such as particles or powder level and tilt transportation,

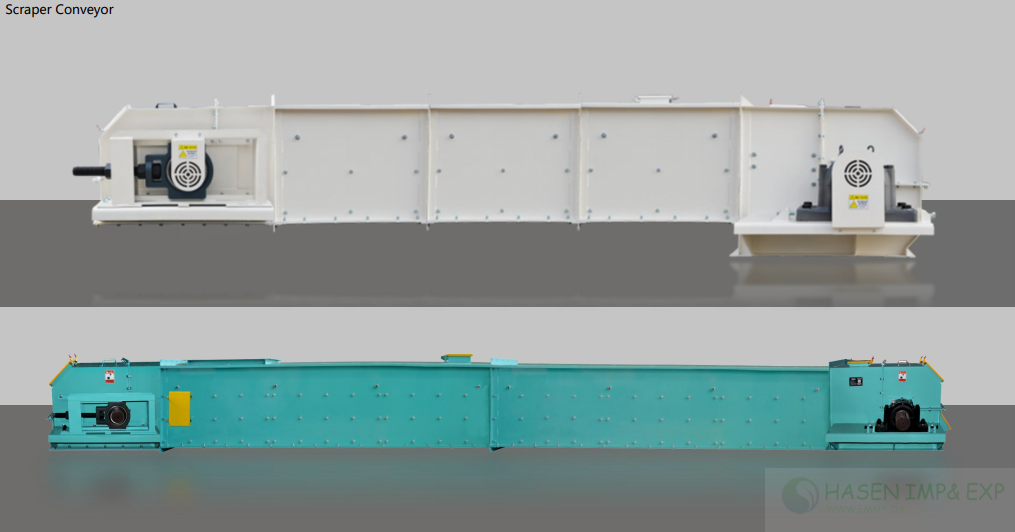

SCRAPER CONVEYOR

Scraper Conveyor for grain,oil,food,wheat,feed,chemical,metallurgy,variety of raw materials,semi finished products.www.immyhitech.com suitable for grain and oil, food, wheat, feed, chemical, metallurgy and other industries to transport a variety of raw materials, semi finished products, such as particles or powder level and tilt transportation,

We provide integrated grain and oil engineering equipment EPC turnkey project from 100 to 5000TPD .

Application:

SCRAPER CONVEYOR Series scraper conveyor is my company according to the introduction of technology development of upgraded products. This product is suitable for grain and oil, food, wheat, feed, chemical, metallurgy and other industries to transport a variety of raw materials, semifinished products, such as particles or powder level and tilt transportation.

SCRAPER CONVEYOR Its characteristics are: simple structure, small size, good sealing performance,reasonable structure, the use of plastic wear plate on the guide rail effectively reduce the noise and material damage rate, while prolonging the service life of the machine. The machine can be started with heavy load and has the characteristics of saving power consumption and easy operation and maintenance.

For more information please visit:

https://youtube.com/shorts/k1_bp3MvJPc?feature=share

https://wordpress.com/read/feeds/141892103/posts/4821900081

https://youtu.be/N39aSTLPAEQ

A scraper conveyor is a type of continuous conveying equipment designed to transport bulk materials such as grains, powders, particles, and semi-finished products through a closed or semi-closed trough using chains with attached scrapers. As the chain moves, the scrapers push or drag materials along the conveyor path. Scraper conveyors are widely used in industries such as grain processing, oil extraction, food manufacturing, feed production, chemical processing, and metallurgy.

Scraper conveyors are highly versatile and suitable for transporting a wide range of materials, including:

Grain (wheat, corn, rice, barley, etc.)

Oilseeds (soybeans, rapeseed, sunflower seed)

Food ingredients (sugar, flour, starch, salt)

Animal feed and feed additives

Chemical raw materials

Metallurgical powders and granules

Semi-finished industrial products

Particles, pellets, flakes, and powder-level materials

Their enclosed structure makes them especially suitable for dusty, fine, or hygroscopic materials.

Scraper conveyors are commonly used in:

Grain and wheat processing plants

Edible oil and oilseed crushing factories

Food and beverage production lines

Animal feed mills

Chemical and pharmaceutical plants

Metallurgy and mineral processing

Bulk material storage and transfer systems

Their ability to handle both horizontal and inclined (tilt) transportation makes them essential in complex production layouts.

A scraper conveyor operates using a motor-driven chain system. Scrapers are fixed at regular intervals on the chain. When the chain moves along the conveyor trough, the scrapers push the material forward. Depending on the design, the conveyor can operate in:

Horizontal transportation

Inclined transportation

Combined horizontal and vertical (tilt) conveying

This mechanism ensures stable flow, minimal material degradation, and controlled conveying speed.

Scraper conveyors offer several key advantages:

Enclosed structure reduces dust pollution and material loss

Stable conveying capacity with uniform material flow

Strong adaptability to powder, granular, and small block materials

Space-saving design, ideal for compact plants

Low energy consumption compared to pneumatic systems

Easy integration into automated production lines

Safe and clean operation, especially in food and chemical industries

Yes. One of the main strengths of scraper conveyors is their ability to handle inclined and tilt transportation. Depending on material characteristics and conveyor design, scraper conveyors can transport materials at significant angles without slipping or rollback. This makes them ideal for applications requiring elevation changes, such as silos, bins, and multi-floor production facilities.

Absolutely. Scraper conveyors are particularly well-suited for powder and fine particle materials, such as flour, cement additives, chemical powders, and metallurgical dust. Their enclosed trough design minimizes dust leakage, improves workplace cleanliness, and protects materials from contamination and moisture.

Common scraper conveyor types include:

Horizontal scraper conveyors

Inclined scraper conveyors

Enclosed scraper conveyors

U-type and rectangular trough conveyors

Heavy-duty scraper conveyors for metallurgy

Food-grade stainless steel scraper conveyors

The choice depends on material properties, conveying distance, capacity, and environmental requirements.

Compared with other conveying equipment:

Vs. Belt conveyors: Scraper conveyors are better for dusty, enclosed, and short-to-medium distance conveying, especially for fine materials.

Vs. Screw conveyors: Scraper conveyors cause less material shear and heat, making them more suitable for fragile or temperature-sensitive products.

Each conveyor type has its advantages, but scraper conveyors excel in sealed, stable, and multi-directional conveying.

Scraper conveyors can be manufactured using:

Carbon steel for general industrial use

Stainless steel (304/316) for food, oil, and chemical industries

Wear-resistant steel for metallurgy and abrasive materials

Material selection depends on corrosion resistance, hygiene standards, and wear requirements.

Scraper conveyors are designed for long service life and low maintenance. Key components such as chains, sprockets, and scrapers are modular and easy to replace. Regular inspection and lubrication ensure reliable operation and reduce downtime.

Yes. Scraper conveyors can be customized according to:

Conveying capacity

Conveyor length and height

Inclination angle

Material characteristics

Food-grade or explosion-proof requirements

Integration with existing production lines

Customization ensures optimal performance for specific industrial applications.

Yes. Due to their enclosed design, scraper conveyors significantly reduce dust emissions and material spillage, contributing to a cleaner and safer production environment. This is especially important in food, chemical, and grain industries, where hygiene and environmental protection are critical.

Key factors include:

Material type and bulk density

Particle size and moisture content

Required conveying capacity

Horizontal or inclined conveying needs

Operating environment (temperature, corrosion, hygiene)

Automation and control requirements

Professional guidance ensures the correct conveyor model and configuration.

Choosing an experienced scraper conveyor manufacturer ensures:

Reliable design and engineering

High-quality materials and components

Compliance with industry standards

Long-term operational stability

Technical support and after-sales service

A professional supplier can provide turnkey conveying solutions tailored to your industry.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000