Bran Dispenser (unloader)

Mainly for discharging granular, flour and flake material with poor fluidity in flour mill, oil mill feed, winery by products and flat bottom bin specially bran cake and other materials.www.immyhitech.com

Mainly for discharging granular, flour and flake material with poor fluidity in flour mill, oil mill feed, winery by products and flat bottom bin specially bran cake and other materials.www.immyhitech.com

WHEAT MAIZE BRAN OUTLET DISPENSER(BRAN UNLAODER) mainly for discharging granlar, flour and flak material with poor fluidity in flour mill, oil mill feed,

winery by products and flat bottom bin specially bran cake and others, We provide integrated grain and oil EPC turnkey project 100TPD to

3000TPD from China.

BRAN OUTLET DISPENSER (BRAN UNLAODER)is mainly used for discharging granular, powdery and flake materials with poor fluidity in flour mill, oil factory,

feed mill, winery, vertical bin of by-products and flat bottom bin, especially bran, cake and other materials with poor fluidity in flour mill

rocker arm elevator contains a number of patented technologies.

Personalized selection:

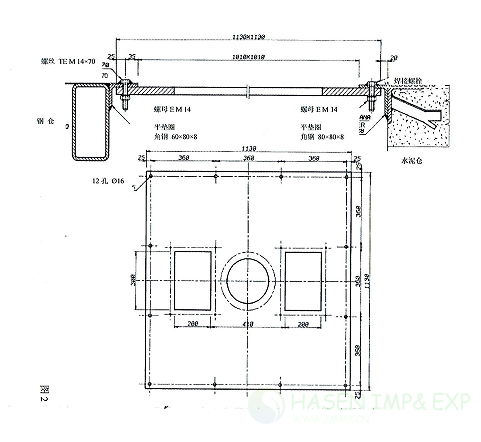

The rocker is available in a variety of sizes from 2 to 5 meters in diameter.

You can choose different models flexibly according to different process and capacity.

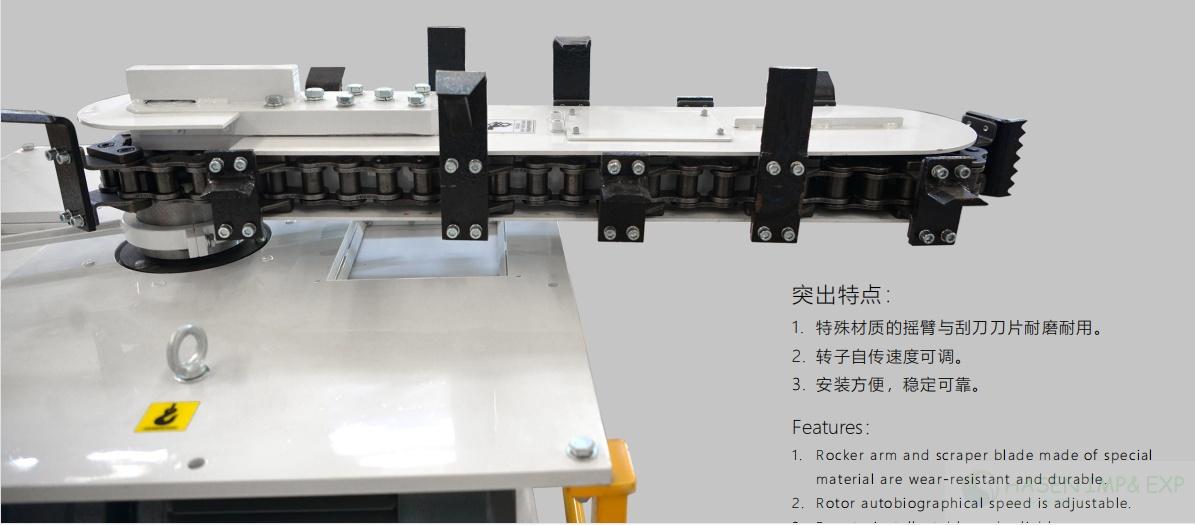

Rocker arm and scraper blade made of special material are wear-resistant and durable.

Rotor autobiographical speed is adjustable.

Easy to install, stable and reliable

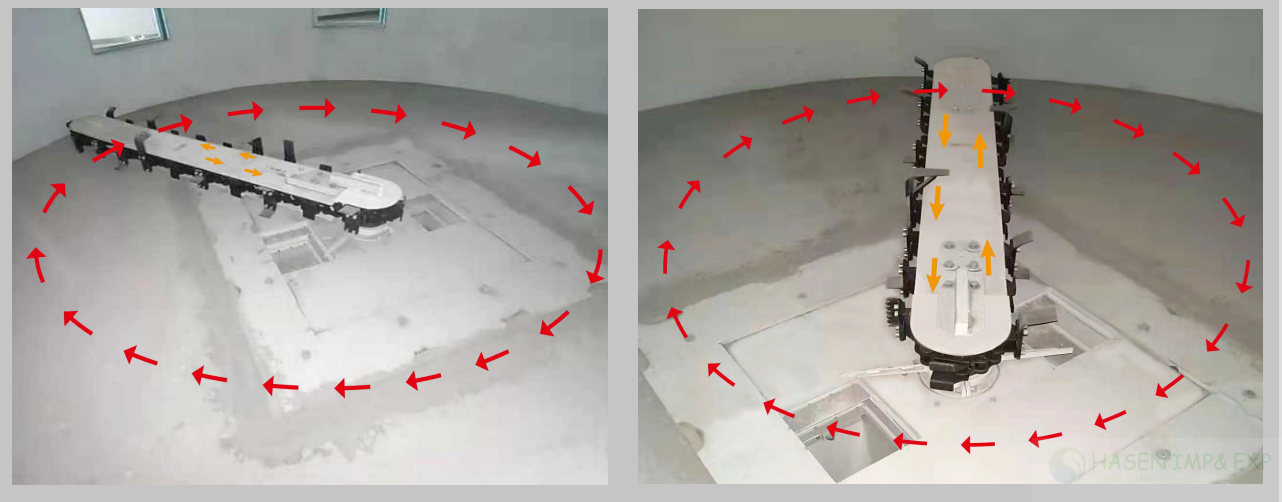

Rotation and revolution swept away the boredom inside(brans) the cabin

For more information please visit:

https://wordpress.com/post/wheatflourmill0.wordpress.com/636

https://youtu.be/_sGsnBJa31c

https://youtu.be/zGmRE1Rk4iU

https://www.facebook.com/maizemachinehasen/

https://www.linkedin.com/feed/update/urn:li:share:7088346630189428736/

https://www.blogger.com/blog/posts/4145872885004376169?hl=zh-CN&tab=jj

https://twitter.com/millmachinecn

https://www.instagram.com/flourmachine/

https://www.threads.net/@flourmachine

BRAN DISCHARGING GRANLAR,FLOUR,FLAKE MATERIAL IN WHEAT MAIZE FLOUR,OIL,FEED,WINERY INDUSTRIES.

A Bran Dispenser (unloader) is a specialized bulk material handling device designed to discharge materials with poor fluidity from silos, bins, or hoppers. In flour mill processing lines, it is mainly used for bran cake, bran flakes, flour by-products, granular materials, and flaky materials that tend to bridge, arch, or compact during storage. Unlike conventional feeders, the bran dispenser ensures continuous, uniform, and blockage-free discharge, especially from flat bottom bins.

In modern flour mill processing lines, by-products such as bran often have low bulk density, high fiber content, irregular particle size, and poor flowability. These characteristics can cause serious discharge problems, including silo blockage, unstable flow rates, and production downtime.

A Bran Dispenser (unloader) solves these challenges by mechanically loosening and guiding the material toward the outlet, ensuring stable flow and improving overall production efficiency.

The Bran Dispenser (unloader) is suitable for a wide range of difficult-to-flow materials, including:

Wheat bran and bran cake

Flour and milling by-products

Granular materials with poor fluidity

Flake materials

Oil mill feed residues

Winery by-products such as grape pomace (dry or semi-dry)

Other fibrous or cohesive bulk solids

This versatility makes it widely used in flour mills, oil mills, feed mills, and food processing plants.

A typical Bran Dispenser (unloader) is installed at the bottom of a bin or silo. It uses rotating arms, paddles, or screw-assisted mechanisms to:

Break material bridges and arches

Prevent material compaction

Guide material evenly toward the discharge outlet

This controlled mechanical action ensures a consistent and mass-flow-like discharge, even when handling bran cake or flaky materials that normally resist gravity flow.

The Bran Dispenser (unloader) is commonly applied in:

Flour mill processing lines

Bran storage silos and flat bottom bins

Oil mill feed handling systems

Winery by-product discharge systems

Animal feed and premix plants

Bulk storage systems for low-flow materials

In flour mills, it plays a critical role in ensuring reliable bran handling after milling and separation.

Yes. One of the major advantages of a Bran Dispenser (unloader) is its suitability for flat bottom bins, where gravity discharge alone is often insufficient. By actively extracting material across the bin bottom, the unloader prevents dead zones and ensures complete emptying, which reduces material residue and improves hygiene.

The Bran Dispenser (unloader) effectively addresses:

Bridging and arching of bran

Ratholing in silos

Irregular or interrupted discharge

Manual intervention and safety risks

Production downtime caused by blockages

By eliminating these issues, flour mills can achieve stable operation and lower maintenance costs.

Stable material flow is essential for automated flour mill processing lines. A Bran Dispenser (unloader):

Maintains constant feed rates

Reduces equipment overload downstream

Minimizes labor intervention

Protects conveyors and screw feeders from sudden surges

As a result, the entire milling line operates more smoothly and efficiently.

Yes. High-quality Bran Dispensers (unloaders) can be customized according to:

Bin diameter and height

Material characteristics

Required discharge capacity

Integration with existing conveyors or pneumatic systems

Customization ensures optimal performance in different flour mill layouts and material conditions.

A typical Bran Dispenser (unloader) consists of:

A robust central drive unit

Radial arms or paddles for material agitation

Heavy-duty wear-resistant components

Sealed bearings suitable for dusty environments

These features ensure long service life, even under continuous industrial operation.

Yes. The Bran Dispenser (unloader) is designed for simple maintenance and long-term reliability. Key wear parts are accessible, and routine inspections can be carried out without dismantling the entire system. Proper maintenance significantly extends service life and reduces unexpected shutdowns.

While screw feeders are effective for free-flowing materials, they often struggle with bran cake and flaky materials. A Bran Dispenser (unloader) works as a primary discharge device, ensuring reliable extraction before material is transferred to a screw conveyor or belt conveyor. This combination provides superior performance in flour mill processing lines.

Absolutely. The Bran Dispenser (unloader) can be integrated with PLC-controlled systems, level sensors, and downstream conveying equipment. This allows precise control of material flow and seamless operation within automated flour mill processing lines.

Industries that handle low-flow or fibrous materials benefit most, including:

Flour milling

Oil milling and feed processing

Brewing and winery by-products handling

Food and agricultural processing

Biomass and fiber-based material storage

The performance of a Bran Dispenser (unloader) heavily depends on engineering design and manufacturing quality. A professional supplier ensures:

Proven design experience

Reliable materials and components

Custom engineering support

Long-term technical service

This is critical for maintaining stable flour mill operations.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000