Bran outlet conveyor for grain and oil new generated conveyor for warehouse twist conveyor according to high moisture content poor fluidity and easy expansion arch of bran,Used in wheat maize flour milling line.www.immyhitech.com

content poor fluidity and easy expansion arch of bran,Used in wheat maize flour milling line. www.immyhitech.com

PRODUCTION WHEAT BRAN OUTLET CONVEYOR

content poor fluidity and easy expansion arch of bran,Used in wheat maize flour milling line-We provide integrated

grain and oil engineering equipment EPC turnkey project from 100TPD to 3000TPD .

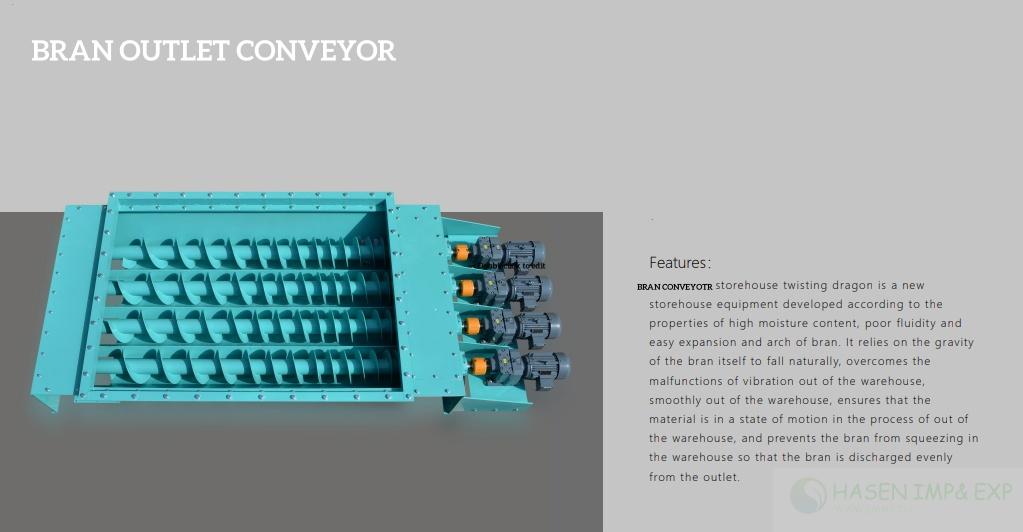

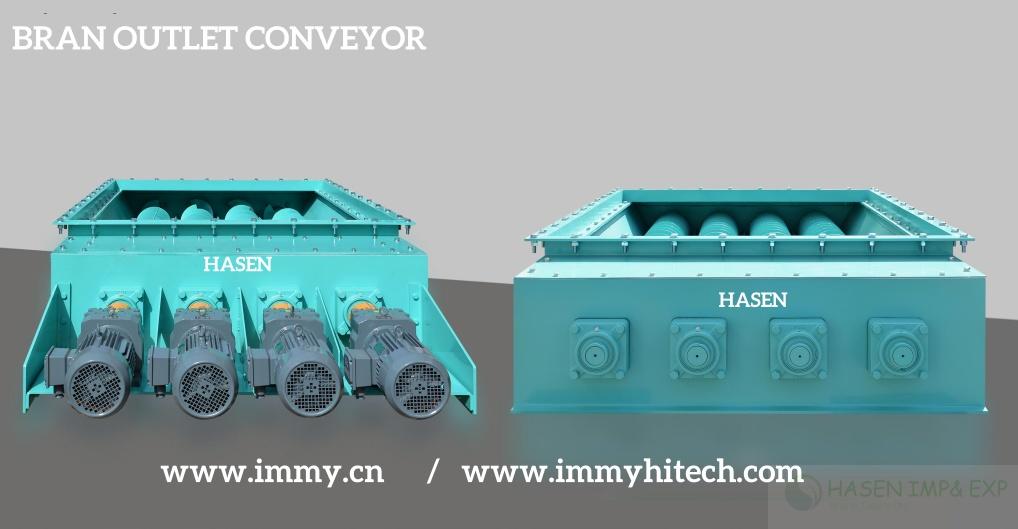

Features:

Bran storehouse twisting dragon is a new storehouse equipment developed according to the properties of high

moisture content, poor fluidity and easy expansion and arch of bran. It relies on the gravity of the bran itself to

fall naturally, overcomes the malfunctions of vibration out of the warehouse, smoothly out of the warehouse,

ensures that the material is in a state of motion in the process of out of the warehouse, and prevents the bran

from squeezing in the warehouse so that the bran is discharged evenly from the outlet.

New generated conveyor for warehouse twist conveyor according to high moisture content poor fluidity and

easy expansion arch of bran,Used in wheat maize flour milling line.

BRAN OUTLET CONVEYOR FOR HIGH MOISTURE CONTENT POOR FLUIDITY BRAN USED IN WHEAT FLOUR MILL

PRODUCTION WHEAT BRAN OUTLET CONVEYOR

BRAN OUTLET CONVEYOR is new generated conveyor for warehouse twist conveyor according to high moisture

content poor fluidity and easy expansion arch of bran,Used in wheat maize flour milling line-We provide integrated

grain and oil engineering equipment EPC turnkey project from 100TPD to 3000TPD .

Bran storehouse twisting dragon is a new storehouse equipment developed according to the properties of high

moisture content, poor fluidity and easy expansion and arch of bran. It relies on the gravity of the bran itself to

fall naturally, overcomes the malfunctions of vibration out of the warehouse, smoothly out of the warehouse,

ensures that the material is in a state of motion in the process of out of the warehouse, and prevents the bran

from squeezing in the warehouse so that the bran is discharged evenly from the outlet.

A bran outlet conveyor for grain and oil processing is a specialized conveying system designed to transport bran, husk, and other light by-products generated during wheat, maize, and flour milling operations. Unlike conventional screw or belt conveyors, this new generated warehouse twist conveyor is engineered to handle materials with high moisture content, poor fluidity, low bulk density, and a strong tendency to form expansion arches.

In modern flour milling lines, bran discharge stability is critical. Any blockage or arching at the outlet can interrupt production, increase downtime, and lead to material waste. The bran outlet conveyor is therefore optimized to ensure continuous, smooth, and clog-free discharge.

Bran has unique physical properties that make conveying challenging:

High moisture content, especially in humid environments

Poor fluidity due to irregular particle shape

Low bulk density, causing bridging and floating

Easy expansion and arch formation at bin and outlet points

Traditional conveyors often fail because they rely on gravity flow or simple rotation. This results in material buildup, blockage, and inconsistent feeding. The warehouse twist conveyor addresses these problems through a structural and mechanical redesign specifically for bran handling.

A warehouse twist conveyor is a new-generation screw-type conveyor featuring a twisted or specially profiled conveying element rather than a traditional straight flight screw. This innovative structure creates multi-directional shear and disturbance, preventing bran from compacting or forming stable arches.

Key working principles include:

Continuous agitation of material at the outlet

Reduced contact area to prevent sticking

Controlled conveying speed to avoid compression

Self-cleaning motion to reduce residue buildup

This makes it ideal for bran outlet applications in grain and oil warehouses, flour mills, and feed processing plants.

The most common problem in bran discharge is arching, where material forms a stable bridge and stops flowing. The new generated bran outlet conveyor solves this through:

Twist structure design that breaks internal friction

Variable pitch conveying elements that disrupt compaction

Optimized outlet geometry to eliminate dead zones

Continuous dynamic flow, rather than static pressure

As a result, even bran with high moisture and poor flowability can be discharged smoothly and reliably.

Yes. The bran outlet conveyor is specifically designed for wheat flour milling lines and maize milling systems. During milling, bran is produced continuously and must be removed efficiently to maintain production balance.

Typical applications include:

Bran discharge from milling machines

Bran collection under plansifters

Transfer to bran silos or warehouses

Feeding systems for bran pelletizing or packaging

Its stable output ensures that downstream equipment operates without interruption.

Absolutely. One of the key advantages of this warehouse twist conveyor is its ability to handle high-moisture bran, even in tropical or coastal environments.

Design features supporting this include:

Anti-adhesion material selection

Smooth inner casing with minimal retention points

Reduced compression conveying principle

Optional wear-resistant and corrosion-resistant coatings

These features prevent material from sticking, swelling, or hardening inside the conveyor.

Compared with traditional screw conveyors, the bran outlet warehouse twist conveyor offers:

Better flow stability for poor-fluidity materials

Lower blockage risk, especially at outlets

Reduced maintenance frequency

Higher operational reliability

Longer service life

Traditional screws are designed for free-flowing materials, while this new generated conveyor is purpose-built for bran and similar difficult materials.

Yes. In grain and oil warehouses, bran and by-products are often stored temporarily before further processing or shipment. The warehouse twist conveyor is ideal for:

Bran unloading from silos

Controlled feeding into transport systems

Preventing material stagnation during storage

Its compact structure and modular design make it easy to integrate into existing warehouse layouts.

By eliminating frequent blockages and manual intervention, the bran outlet conveyor significantly improves production efficiency:

Reduces unplanned downtime

Ensures continuous milling operation

Minimizes labor requirements

Prevents material loss and contamination

Stable bran discharge also helps maintain balanced airflow and pressure inside the milling system, improving overall product quality.

Yes. The new generated bran outlet conveyor can be customized according to:

Throughput capacity

Installation angle and space constraints

Material characteristics

Connection with upstream and downstream equipment

This flexibility allows it to be used in small flour mills, large industrial milling plants, and integrated grain and oil processing facilities.

Bran Outlet Conveyor for grain, oil, animal feed, winery,chemicals, pharmaceutical etc industries.www.immyhitech.com

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000