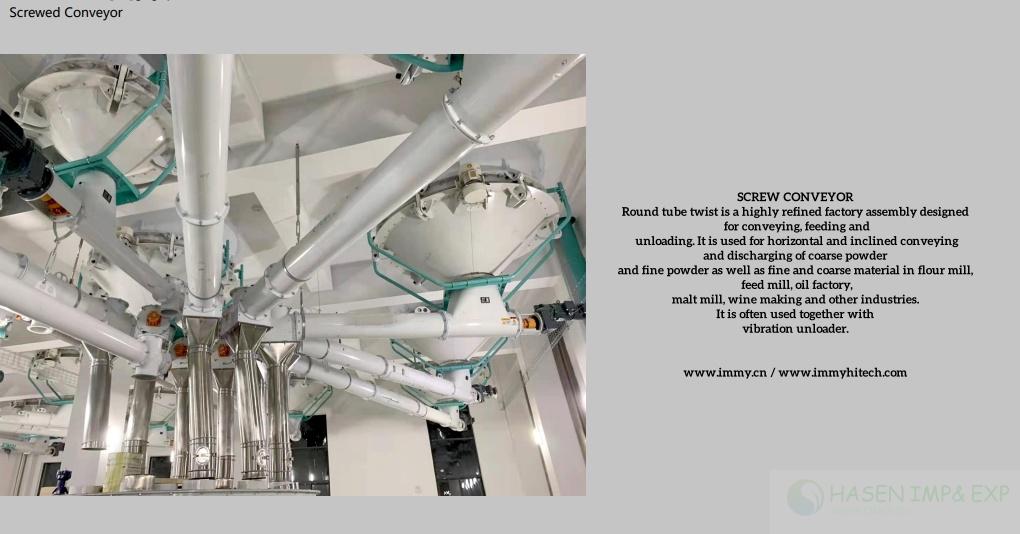

Screw Conveyor Round Tube twist is a highly refined factory assembly designed for conveying, feeding and unloading. It is used for horizontal and inclined conveying and discharging of coarse powder and fine powder as well as fine and coarse material in flour mill, feed mill, oil factory, malt mill, wine making and other industries. It is often used together with vibration unloader. www.immyhitech.com

SCREW CONVEYOR Screw Conveyor Round Tube twist is a highly refined factory assembly designed for conveying, feeding and unloading. It is used for horizontal and inclined conveying and discharging of coarse powder and fine powder as well as fine and coarse material in flour mill, feed mill, oil factory, malt mill, wine making and other industries. It is often used together with vibration unloader. www.immyhitech.com

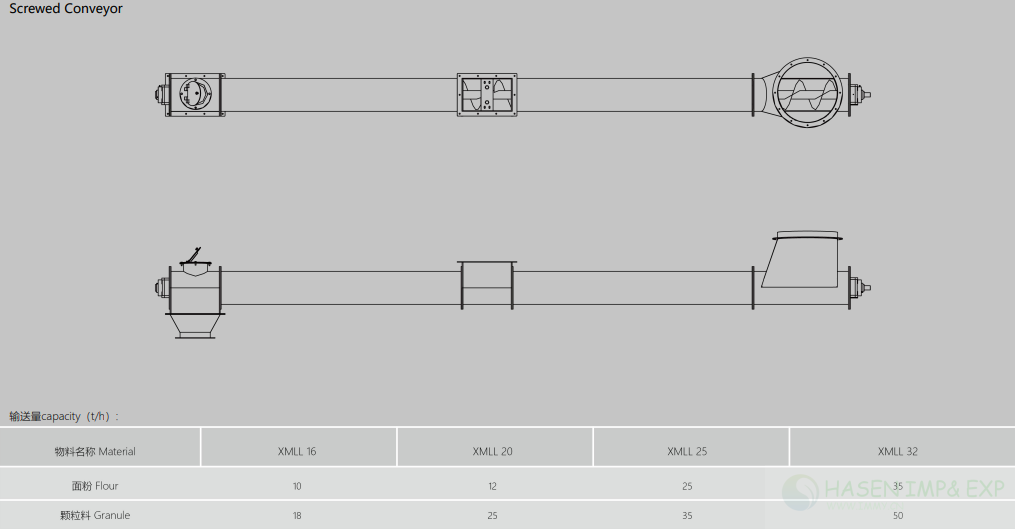

The sealing structure is reliable, clean, sanitary and free of residue; Special feed inlet design, no arching of materials, full length cleaning door maintenance,convenient cleaning;

The middle suspension bearing has good wear resistance and needs no maintenance;

Modular design, can be extended and combined arbitrarily, up to 12m;

Strong conveying performance, suitable for conveying, distribution and unloading of multiple feed ports and discharge ports.

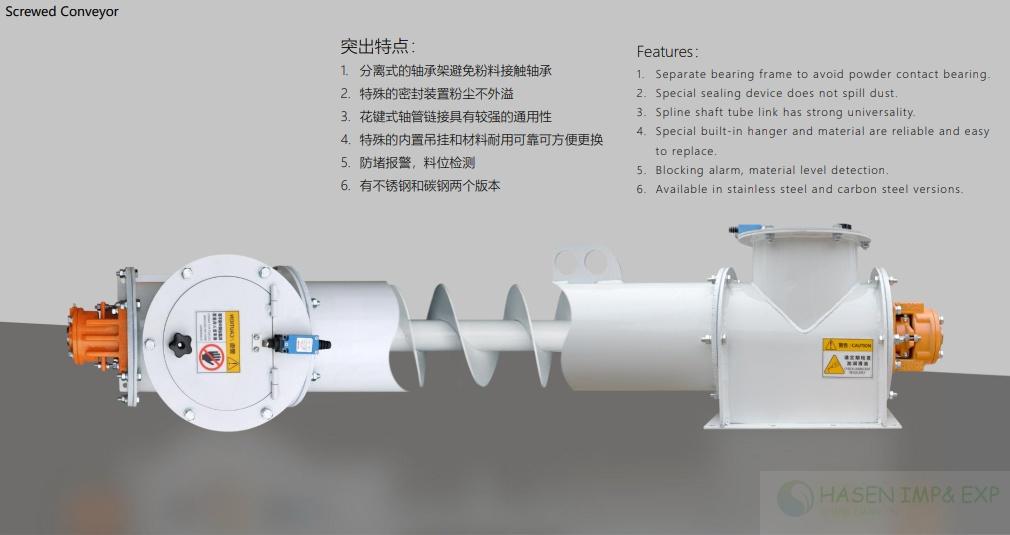

Separate bearing frame to avoid powder contact bearing.

Special sealing device does not spill dust.

Spline shaft tube link has strong universality.

Special built-in hanger and material are reliable and easy to replace.

Blocking alarm, material level detection.

Available in stainless steel and carbon steel versions.

For more information please visit:

https://wordpress.com/stats/post/800/wheatflourmill0.wordpress.com

https://www.blogger.com/blog/post/edit/4145872885004376169/4641448540248052883

https://www.instagram.com/flourmachine/

https://www.facebook.com/flourmachinechina

https://www.linkedin.com/company/28728730/admin/feed/posts/

https://www.youtube.com/@wheatmaizemillingmachinema3053/about

https://youtu.be/N39aSTLPAEQ

Screw Conveyor Round Tube twist is a highly refined factory assembly designed for conveying, feeding and unloading. It is used for horizontal and inclined conveying and discharging of coarse powder and fine powder as well as fine and coarse material in flour mill, feed mill, oil factory, malt mill, wine making and other industries. It is often used together with vibration unloader. www.immyhitech.com

A SCREW CONVEYOR Screw Conveyor Round Tube twist is a highly refined factory-assembled conveying system designed for efficient conveying, feeding, and unloading of bulk materials. It consists of a rotating helical screw (twist) enclosed in a round tube, which moves materials smoothly from one point to another. This type of screw conveyor is widely used for both horizontal and inclined conveying of powders, granules, and small lump materials across many industrial applications.

The SCREW CONVEYOR Screw Conveyor Round Tube twist is suitable for conveying a wide range of materials, including coarse powder, fine powder, granules, fine materials, and coarse materials. Typical materials include flour, grain, feed, oilseed meal, malt, sugar, sand, chemical powders, and similar bulk solids. Its enclosed round tube design helps reduce dust, spillage, and contamination during material transport.

The SCREW CONVEYOR Screw Conveyor Round Tube twist is extensively used in industries such as flour mills, feed mills, oil factories, malt mills, wine-making facilities, chemical plants, food processing factories, and agricultural processing units. Due to its compact structure and reliable performance, it is also widely adopted in bulk material handling systems where cleanliness, efficiency, and controlled discharge are required.

The primary functions of a SCREW CONVEYOR Screw Conveyor Round Tube twist include conveying, feeding, and unloading bulk materials. It can transfer materials between processing stages, feed materials into mixers or reactors, and discharge finished or semi-finished products. The system ensures continuous, stable, and controllable material flow, making it an essential component in automated production lines.

Yes, the SCREW CONVEYOR Screw Conveyor Round Tube twist is designed for both horizontal and inclined conveying. For inclined applications, the screw design, pitch, and rotational speed are optimized to reduce material backflow and maintain conveying efficiency. Inclined screw conveyors are commonly used where space constraints or process layouts require vertical or angled material transfer.

The round tube structure of the SCREW CONVEYOR Screw Conveyor Round Tube twist offers several advantages, including excellent sealing performance, reduced dust leakage, improved hygiene, and enhanced structural strength. Compared with U-shaped trough screw conveyors, the round tube design provides better rigidity, making it suitable for longer conveying distances and higher operating stability.

A SCREW CONVEYOR Screw Conveyor Round Tube twist improves production efficiency by enabling continuous material flow with minimal manual intervention. Its stable conveying speed ensures consistent feeding rates, reduces downtime, and supports automated production systems. The enclosed design also minimizes material loss, ensuring higher yield and cleaner working environments.

Yes, the SCREW CONVEYOR Screw Conveyor Round Tube twist is particularly suitable for fine powders. The enclosed tube prevents dust dispersion, while precision-manufactured screw blades ensure smooth and uniform material movement. This makes it ideal for handling flour, starch, chemical powders, and other fine particulate materials.

The SCREW CONVEYOR Screw Conveyor Round Tube twist is often used together with a vibration unloader. The vibration unloader helps loosen and evenly discharge materials from storage bins or silos, while the screw conveyor transports the material efficiently to the next process. This combination significantly improves unloading efficiency and prevents material bridging or blockage.

Most SCREW CONVEYOR Screw Conveyor Round Tube twist systems are manufactured using high-quality carbon steel, stainless steel, or wear-resistant alloy steel, depending on application requirements. For food and pharmaceutical industries, stainless steel is commonly used to meet hygiene and corrosion-resistance standards. Surface treatments such as polishing or coating can also be applied to extend service life.

Maintenance of a SCREW CONVEYOR Screw Conveyor Round Tube twist is relatively simple. Regular inspection of bearings, seals, and screw blades is recommended. Proper lubrication and timely replacement of worn components help maintain optimal performance. The robust factory-assembled design ensures long service life with minimal maintenance costs.

Yes, SCREW CONVEYOR Screw Conveyor Round Tube twist systems can be customized according to conveying capacity, length, inclination angle, material characteristics, and installation environment. Customization options include screw diameter, pitch, motor power, discharge outlets, and material of construction, ensuring the system meets specific operational requirements.

The SCREW CONVEYOR Screw Conveyor Round Tube twist is designed for energy-efficient operation. Its optimized screw geometry and stable drive system minimize power consumption while delivering reliable conveying performance. Energy efficiency helps reduce operational costs and supports sustainable industrial practices.

Safety is a key feature of the SCREW CONVEYOR Screw Conveyor Round Tube twist. The enclosed tube structure prevents accidental contact with moving parts, while reliable seals reduce dust-related hazards. Optional safety features such as overload protection, emergency stop systems, and speed monitoring can further enhance operational safety.

A factory-assembled SCREW CONVEYOR Screw Conveyor Round Tube twist ensures high manufacturing precision, consistent quality, and reliable performance. Pre-assembly and testing reduce installation time and minimize commissioning issues on-site, allowing customers to quickly integrate the system into their production lines.

The SCREW CONVEYOR Screw Conveyor Round Tube twist is a highly refined factory assembly designed for conveying, feeding, and unloading. With its ability to handle coarse powder, fine powder, and both fine and coarse materials, it is an indispensable solution for flour mills, feed mills, oil factories, malt mills, wine-making facilities, and many other industries. Its enclosed round tube design, compatibility with vibration unloaders, and customizable configurations make it a reliable, efficient, and cost-effective material handling system.

Please contact with WUXI HASEN (www.immyhitech.com) Screw Conveyor Round Tube twist is a highly refined factory assembly designed for conveying, feeding and unloading.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000